Concrete for high-durability construction

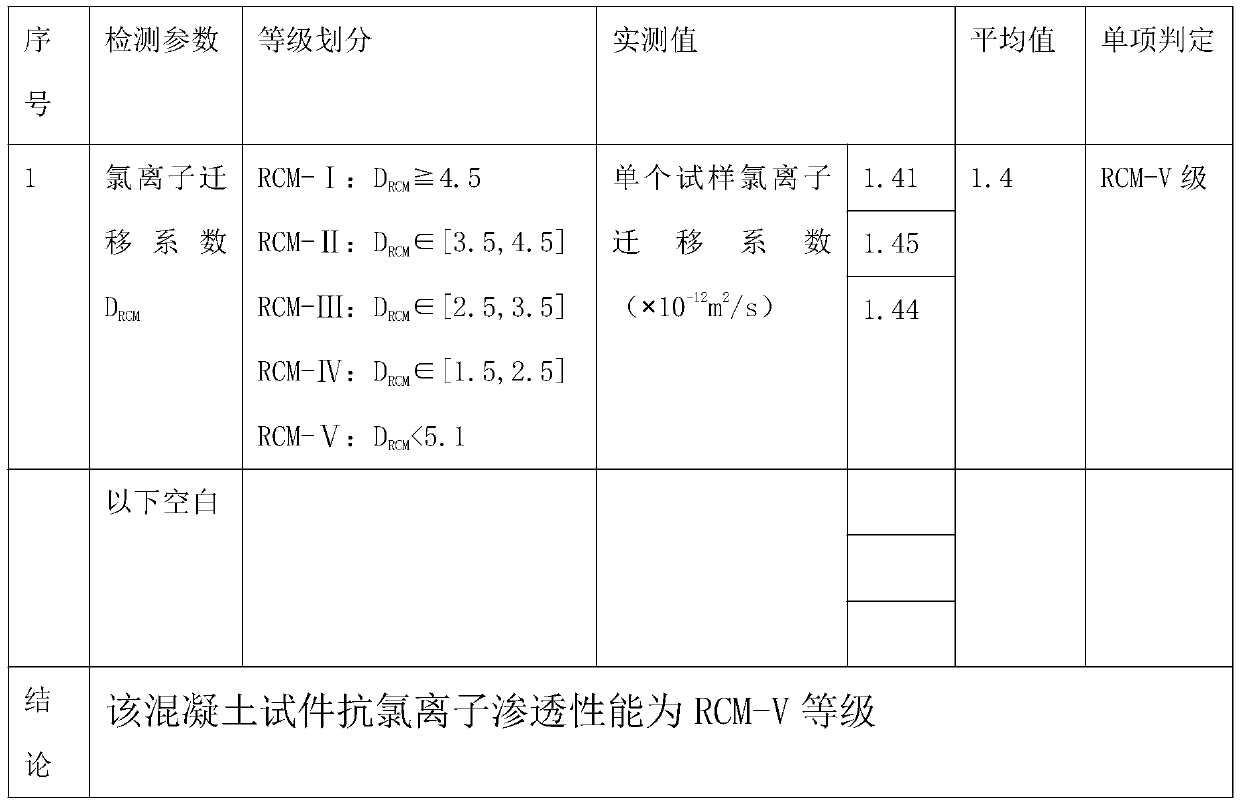

A kind of durability and concrete technology, applied in the field of construction materials, can solve the problems of anti-chloride ion permeability crossover, long construction period, etc., achieve good durability, wide application range, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]In this embodiment, the concrete includes the following raw materials in parts by mass:

[0043] 155 parts of cement, 110 parts of limestone powder, 20 parts of mineral powder, 780 parts of water sand, 1160 parts of pebble, 1010 parts of crushed stone and 155 parts of water;

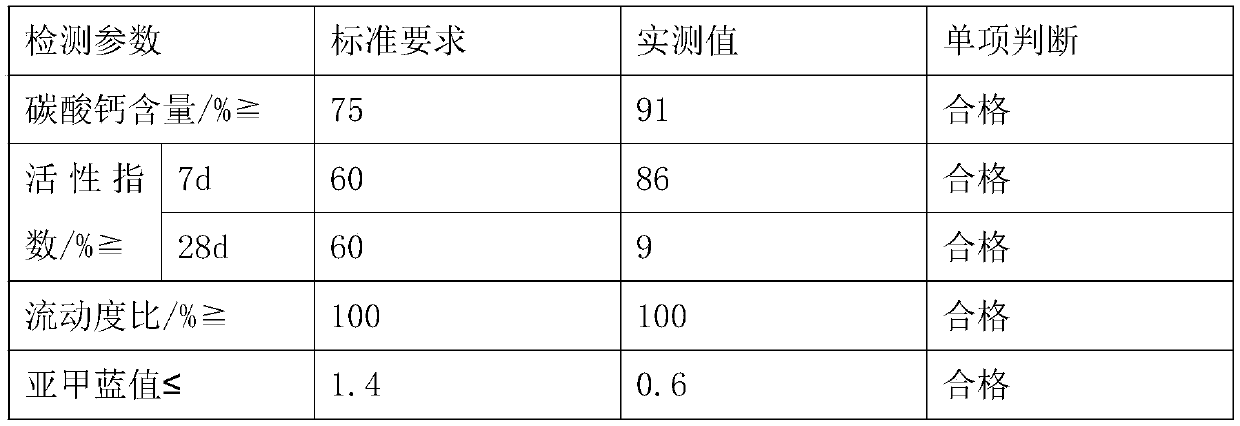

[0044] In the present embodiment, the specific surface area of limestone powder is 550m 2 / kg.

[0045] In the present embodiment, the unit water consumption of limestone powder is 8Kg; Calcium carbonate content is 80%, and the flow ratio of limestone powder is 100%; Particle diameter is 20mm; The methylene blue value of limestone powder is 0.6.

[0046] In the prior art, the calcium carbonate content in the limestone powder is mostly stipulated to be not less than 75%. Although it meets the requirements, the calcium carbonate in the limestone powder is hydrated with cement to produce basic calcium carbonate, and CaCO 3 to C 3 S hydration has a good promoting effect and can increase strength, ...

Embodiment 2

[0051] In this embodiment, the concrete includes the following raw materials in parts by mass:

[0052] 400 parts of cement, 80 parts of limestone powder, 60 parts of mineral powder, 750 parts of water sand, 1150 parts of pebble, 980 parts of crushed stone and 160 parts of water;

[0053] In the present embodiment, the specific surface area of limestone powder is 550m 2 / kg.

[0054] In the present embodiment, the unit water consumption of limestone powder is 8Kg; Calcium carbonate content is 85%, and the flow ratio of limestone powder is 100%; Particle diameter is 20mm; The methylene blue value of limestone powder is 0.8.

[0055] In this embodiment, the apparent density of crushed stone is 2710kg m -3 , the bulk density of the crushed stone is 1570, the needle flake content of the crushed stone is 5%, the crushing value of the crushed stone is 10%, and the gradation of the crushed stone is 5mm.

[0056] In this embodiment, fly ash is also included, and the added amount ...

Embodiment 3

[0061] In this embodiment, the concrete includes the following raw materials in parts by mass:

[0062] 155 parts of cement, 60 parts of limestone powder, 20 parts of mineral powder, 780 parts of water sand, 1010 parts of gravel and 160 parts of water;

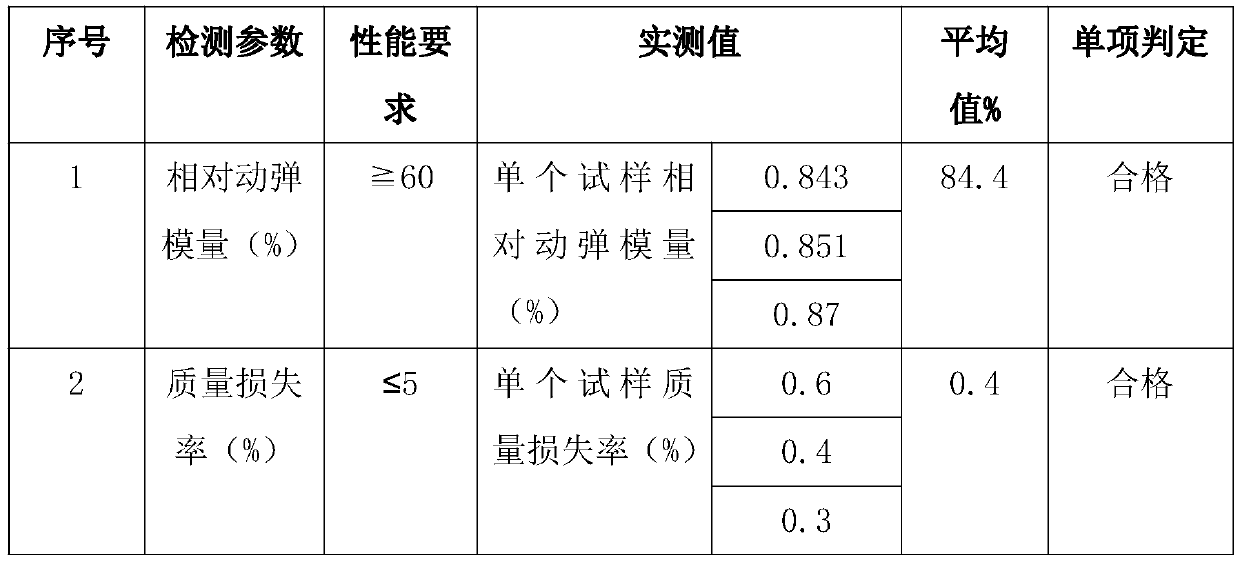

[0063] In this embodiment, although there are no pebbles, the strength of concrete is provided by crushed stones and mineral powder.

[0064] In the present embodiment, the specific surface area of limestone powder is 550m 2 / kg.

[0065] In the present embodiment, the unit water consumption of limestone powder is 9Kg; Calcium carbonate content is 91%, and the flow ratio of limestone powder is 105%; Particle diameter is 50mm; The methylene blue value of limestone powder is 1.0.

[0066] In this embodiment, the apparent density of crushed stone is 2710kg m -3 , the bulk density of the crushed stone is 1570, the needle flake content of the crushed stone is 5%, the crushing value of the crushed stone is 10%, and the gradatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Expansion | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com