Pipeline outer wall anti-corrosion cathode protection device and construction installation method of filling material thereof

A technology for pipeline outer wall and cathodic protection, applied in pipeline anticorrosion/rust protection, pipeline protection, damage protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

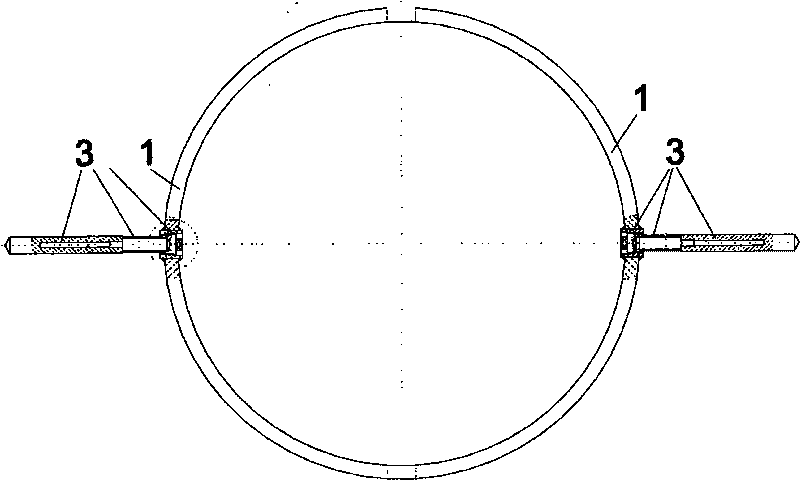

[0084] The construction and installation method of the anti-corrosion cathodic protection device for the outer wall of the pipeline and its packing material. The process pipeline is a pipeline for pipe jacking construction in sections, and the sections are fixed together by welding; The sacrificial anode protection device 3 on the outer wall, the entire pipeline is provided with a protective coating; the main points are:

[0085] 1) After the joints are welded and coated with the joint coating, the installation method of the sacrificial anode protective device for the corrosion control of the outer wall of the pipeline is specifically as follows:

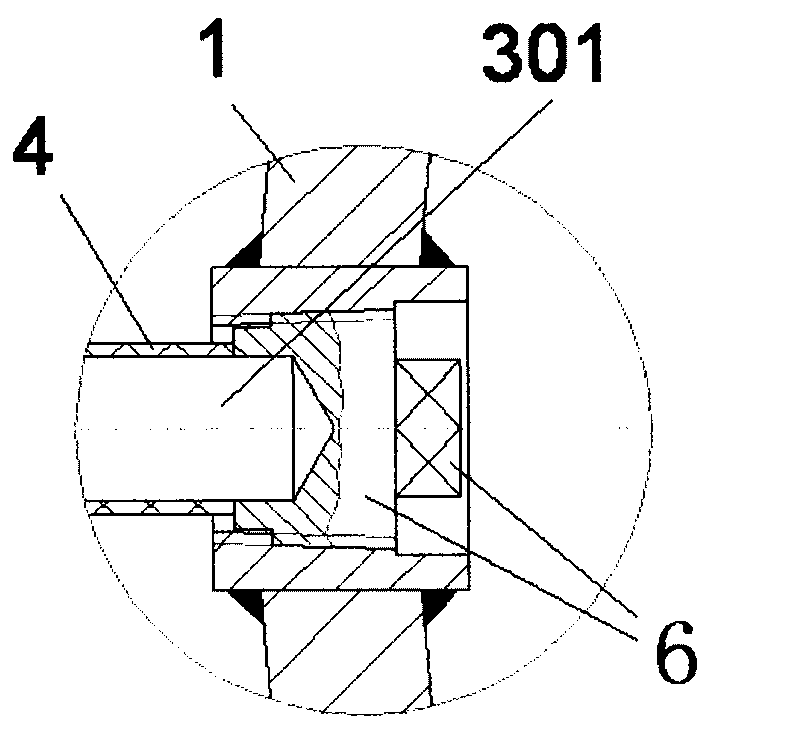

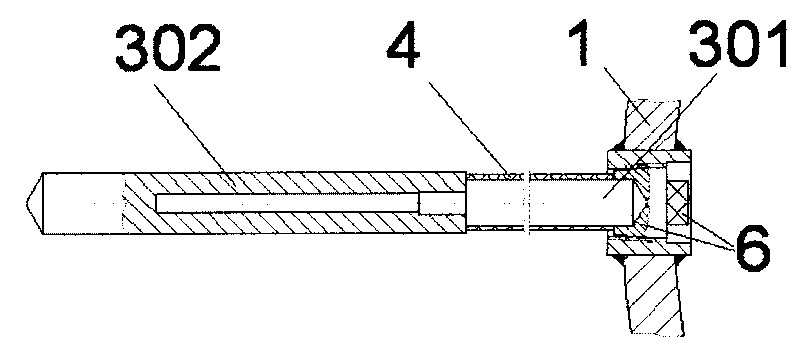

[0086] First, use the grouting hole on the pipe wall of the pipe 1 or punch a hole in the pipe as the installation hole, and inject the pasty sacrificial anode filling material into the hole;

[0087] Then, install the sacrificial anode protection device 3 from the inside of the pipeline to the outside of the pipeline: install the s...

Embodiment 2

[0113] The content of this embodiment is basically the same as that of Embodiment 1, and its difference mainly lies in:

[0114] The mass percentage composition of the pasty sacrificial anode filling material meets the following requirements: bentonite: gypsum powder: industrial sodium sulfate=20:75:5.

[0115] The plug 6 is riveted or welded to the supporting steel rod as the supporting connection part 301 ; the plug 6 and the pipe 1 are connected by welding or clamping.

[0116] The outer wall coating of the pipeline is specifically fused-bonded epoxy high-performance and long-life pipeline coating (SEBF1-7 series coatings produced by the Institute of Metal Research, Chinese Academy of Sciences, which are commercially available products); SEBF1-7 series coatings are suitable for different pipelines , can be selected according to the specific situation.

[0117] The coating materials used for jointing on the outer wall of the road can be:

[0118] The SEBF1~7 series of fusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com