High-performance low-prestressed concrete hollow square pile

A technology of low prestress and hollow square piles, which is applied in the foundation field of buildings, can solve the problems affecting the durability of prefabricated piles, the lack of protection measures for connections, and the shortened service life of buildings, so as to meet the requirements of green construction and solve the problem of piling illusion , The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below:

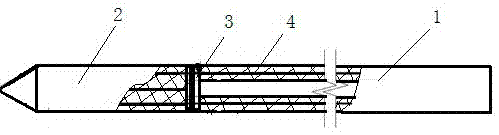

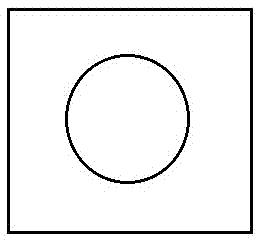

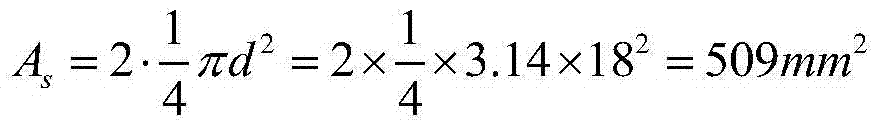

[0022]As shown in the figure, a high-performance low prestressed concrete hollow square pile includes a pile body 1, a pile head 2, and the pile body 1 is composed of at least one unit pile. It is characterized in that the section of the unit pile is a square with a round hole in the center. shape, the pile wall of the unit pile is composed of concrete and parallel steel bars 4 with a prestress of 0.1σ-0.8σ in the concrete, the two ends of the unit pile are respectively provided with connecting plates 3, and the two ends of the steel bars 4 are respectively connected to the connecting plates 3-phase connection, the adjacent unit piles are welded by the connecting plate to form the pile body, the thickness of the connecting plate 3 is 8-16mm, the connecting plate 3 is located at both ends of the unit pile mold, and the distance between the connecting plates 3 is the length of the unit pile, generally 1.0 -2.0mm, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com