Machining and manufacturing method for thermal insulation type steel frame roof panels

A technology for processing and manufacturing roof panels, which is applied in the field of steel frame thermal insulation and light-weight roof panels, can solve the problems of insufficient corrosion allowance, high energy consumption, waste of resources, etc., so as to reduce processing procedures, reduce production costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

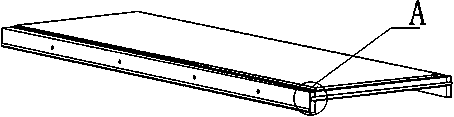

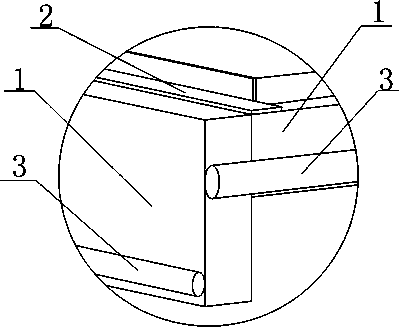

[0024] Such as figure 1 with figure 2 As shown, this embodiment includes the following steps:

[0025] (A) Weld four channel steels 1 and four triangle steels 2 into a standard rectangular frame, first weld two parallel angle steels 2 on a pair of parallel channel steels 1, so that the angle steels 2 and channel steel 1 The surface forms steps;

[0026] (B) The steel mesh is welded within the rectangular frame, and the steel mesh is located in the middle of the frame;

[0027] (C) After the filling material is laid in the rectangular frame, the roof panel can be formed, and the filling material is filled between the two triangle steels 2 to form a plane, and the angle steel 2 forms a step with the surface of the rectangular frame, and the two adjacent roof panels The steps form recesses for caulking the gaps between the roof panels. During production, build a step first, the width of the step matches the distance between the two supports on the frame, lay a plastic film o...

Embodiment 2

[0029] Such as figure 2 As shown, this embodiment is based on Embodiment 1. The channel steel 1 in the step (A) includes an upper surface and a lower surface parallel to each other, and a side surface connecting the upper surface and the lower surface. The upper surface of the channel steel 1 The surface, the side surface and the lower surface are connected sequentially.

[0030] One side of the rectangular frame in the step (A) is a plane, on which a pair of channel steel 1 is welded on the surface of the angle steel 2, one side of the triangle steel 2 is located in the plane of the frame, and the other side is perpendicular to the plane of the frame.

[0031] In the step (A), the height of one pair of the four channel steels 1 is greater than that of the other pair, and the channel steel 1 with the larger height protrudes from the channel steel 1 with the smaller height to form two supporting parts. In order to protect the filling material from external force and prevent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com