Comprehensive protective system for open-cut subway station under strongly corrosive environment and construction method for comprehensive protective system

A protection system and strong corrosion technology, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve problems such as failure to meet the durability requirements of concrete, achieve simple and flexible construction procedures, strong operability, and improve corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in combination with specific embodiments.

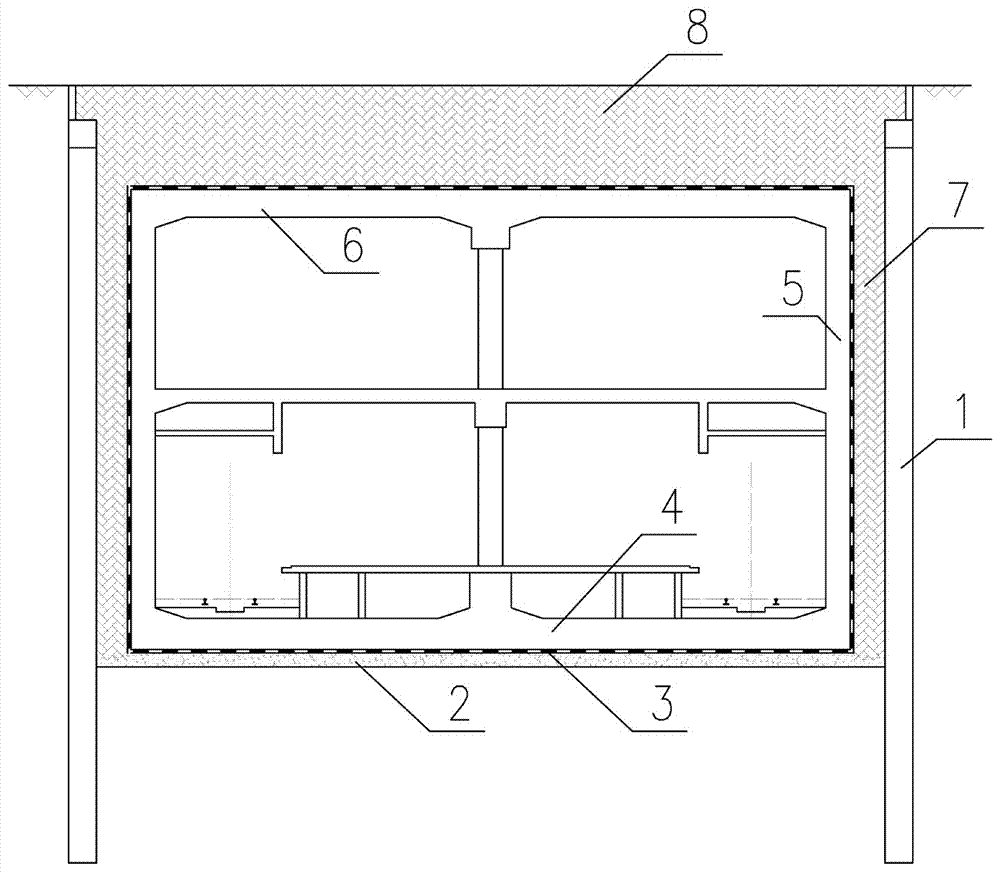

[0040] The comprehensive protection system of subway open excavation stations under the strong corrosion environment involved in the present invention mainly includes structural self-waterproof and anti-corrosion + reinforced anti-corrosion layer + reinforced waterproof layer + isolation layer, and the specific structure is:

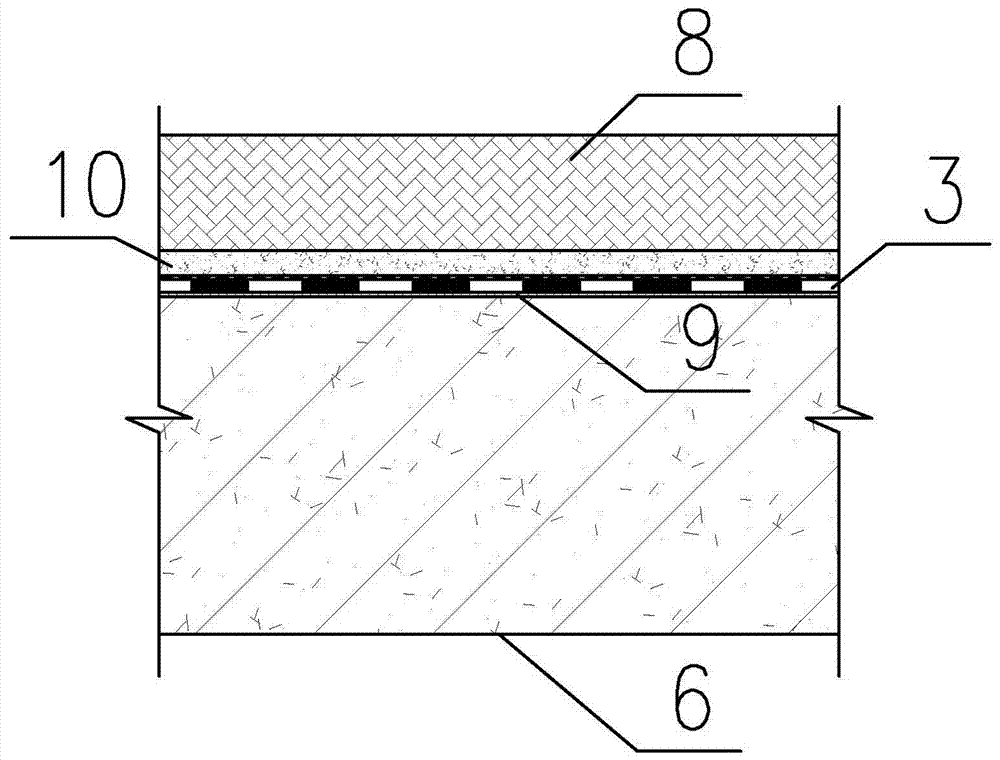

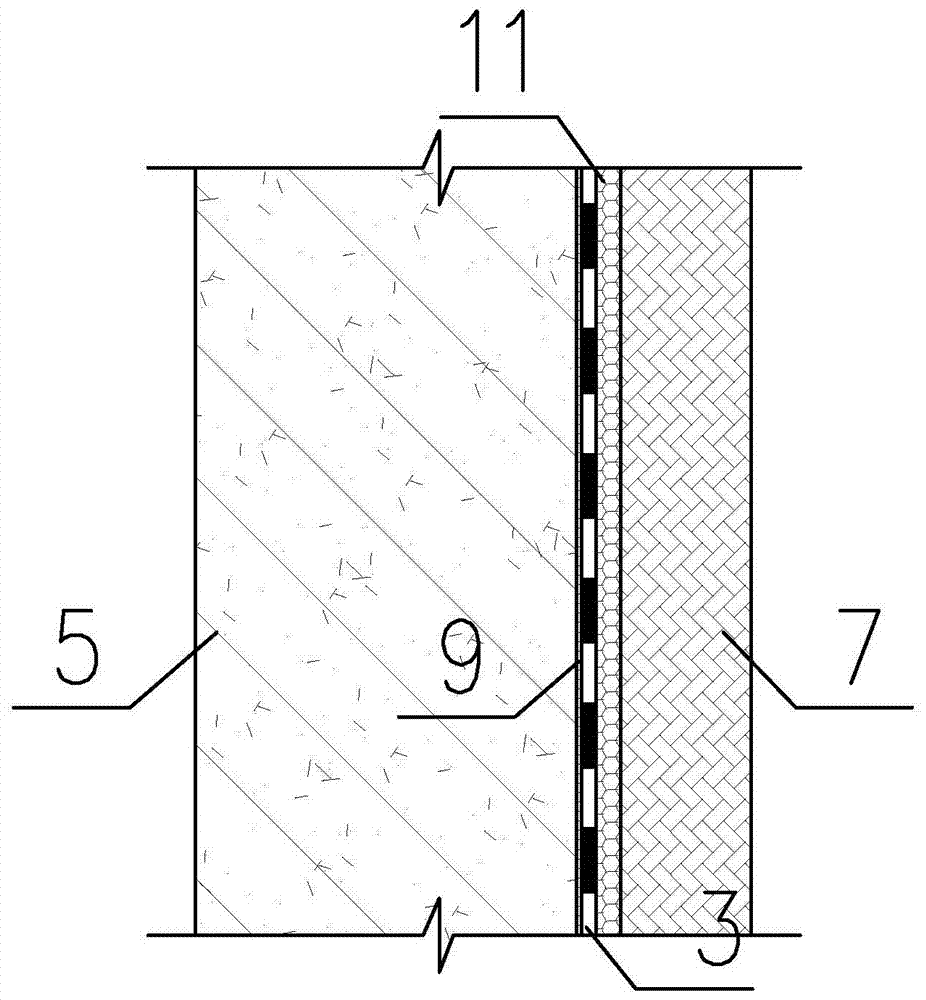

[0041] A fully-wrapped reinforced waterproof layer 3 is arranged outside the top plate 6, the bottom plate 4 and the side wall 5 of the station. The top of the reinforced waterproof layer 3 of the top plate 6 is compacted by the covering soil layer 8, the plain concrete cushion layer 2 is arranged under the reinforced waterproof layer 3 of the bottom plate 4, and the outer side of the reinforced waterproof layer 3 of the side wall 5 and the foundation pit support of the main body of the station on the outer side of the side wall 5 The protective str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com