Self-repairing conversion permeation type antirust coating based on rusty matrix and preparation method thereof

An anti-rust coating and self-repairing technology, which is applied in the field of anti-corrosion coatings, can solve the problems of complex construction and difficult control of the proportion, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

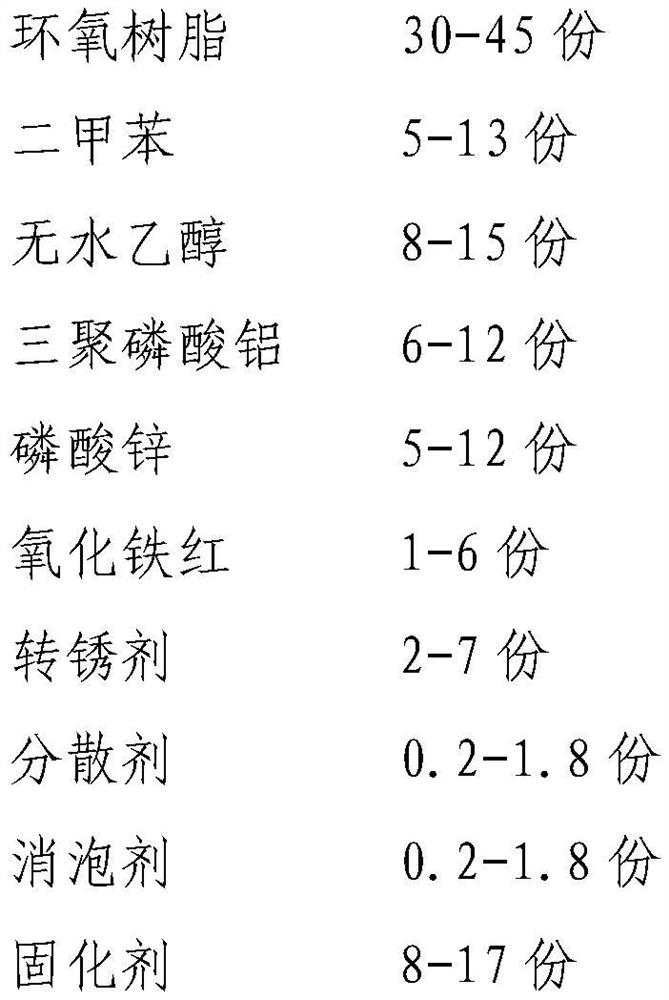

[0056] The technical scheme of the present invention is described below according to the detailed preparation method.

[0057] First prepare the rust-reducing agent: according to the mass ratio of phosphoric acid and potassium ferrocyanide is 7:1. Weigh phosphoric acid and put it into a container and stir it with a magnetic stirrer. Slowly add potassium ferrocyanide into phosphoric acid to prevent ferrocyanide Potassium chloride agglomerated, sealed after adding and continued to stir for about 1.5h. Pour into an airtight container when done.

[0058] Preparation method of self-repairing conversion penetrating antirust coating based on rusty substrate:

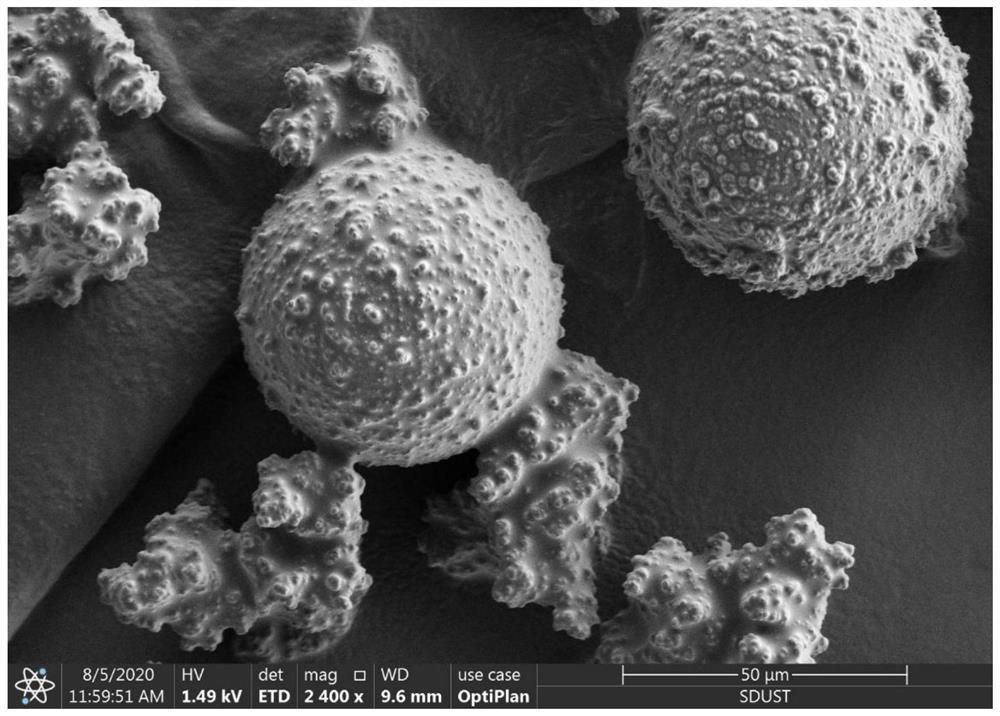

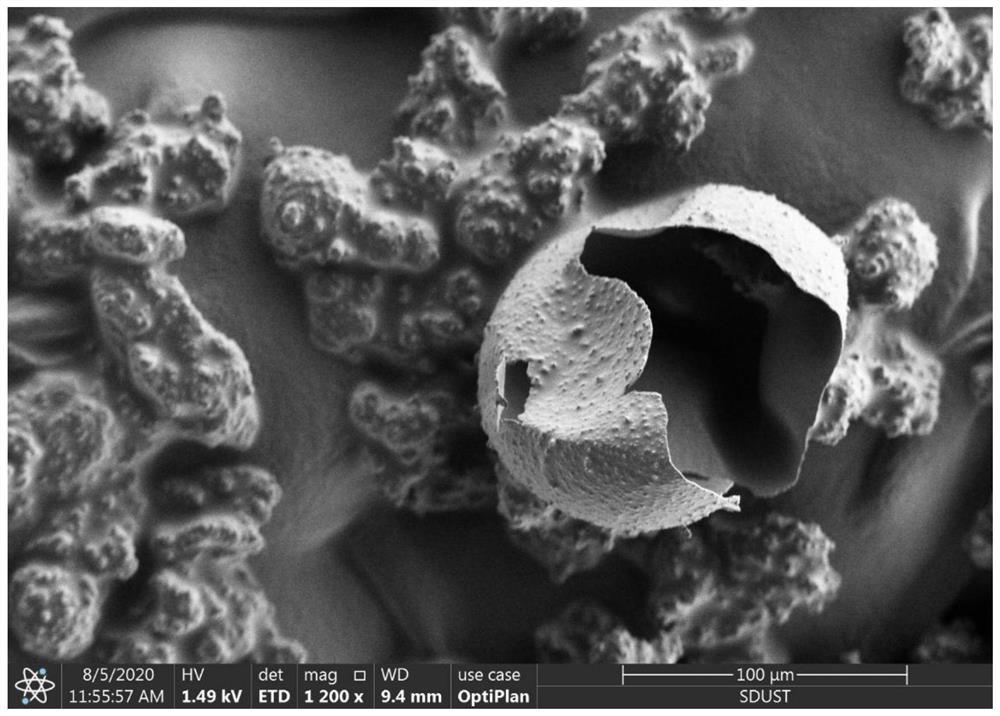

[0059] Step 1: Preparation of self-healing microcapsules

[0060] 1.1: Mix 5.00kg of urea and 10L of formaldehyde solution with a concentration of 37%, add to the container and stir to dissolve, adjust the pH value to 8-9 with triethanolamine, heat in a water bath at 70°C for 1 hour to prepare a urea-formaldehyde resin prepol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com