Electric flocculation method and device for recovering and processing desulfurized wastewater

A technology for desulfurization wastewater, recycling and treatment, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problem of increasing flue gas humidity or HCl content, low temperature corrosion of electrostatic precipitators, and high investment. problem, to achieve the effect of wide processing range, good processing effect and high processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

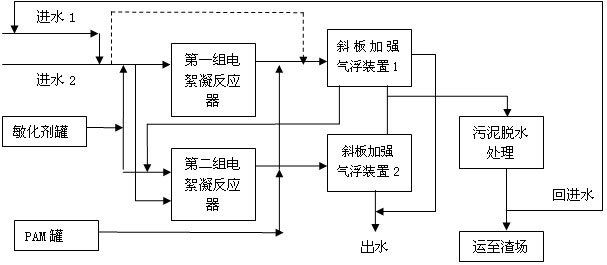

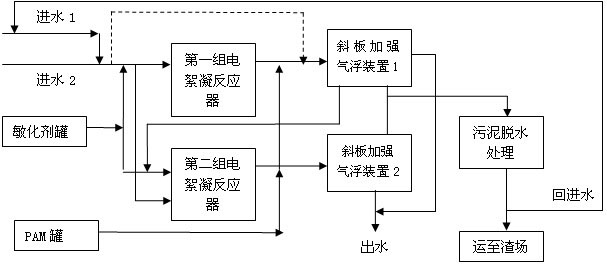

[0084] Embodiment 1 of the present invention: a method for electrocoagulation recovery and treatment of desulfurization wastewater: desulfurization wastewater is collected into the electrocoagulation reactor, and a sensitizer is added to the electrocoagulation reactor by a medicament addition system at a rate of 0.2 kg / ton of water (water Commonly used sensitizers in the treatment field, purchased from the market), the pH value in the reactor is controlled at 5-8, the working pressure is 0.2-0.5Mpa, the working water temperature

[0085] 10-20°C; then use the inclined plate to strengthen the air flotation device for solid-liquid separation, add polyacrylamide (PAM) 2PPM to the solid-liquid separation system through the chemical addition system, the air-water ratio of the air flotation device is 11:1, and the separation Area surface load 8 ~ 12m 3 / (h.m 2 ); the separated clarified effluent is returned to the ash flushing system of the power plant, and the sludge is transporte...

Embodiment 2

[0093] Embodiment 2 of the present invention: the method for electrocoagulation recovery and treatment of desulfurization wastewater: desulfurization wastewater is collected into the electrocoagulation reactor, and a sensitizer (purchased on the market) is added to the electrocoagulation reactor by 0.2 kg / ton of water through the medicament addition system ), the PH value in the reactor is controlled at 4-9, the working pressure is 0.1-0.6Mpa, and the working water temperature is 5-15°C; then the inclined plate is used to strengthen the air flotation device for solid-liquid separation, and the chemical addition system is added to the solid-liquid separation system Add polyacrylamide (PAM) 2PPM, the air-water ratio of the air flotation device is 10:1, and the surface load of the separation area is 5.4-10m 3 / (h.m 2 ); the separated clarified effluent is directly discharged, the sludge is transported to the sludge treatment system for dehydration, and the effluent of the sludge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com