Electrolytic cleaning tank adopting polar plate polarity-unchanging middle conductor method

An electrolytic cleaning and intermediate conductor technology, applied in the electrolytic process, electrolytic components, etc., can solve the problems of limiting the cleaning efficiency and cleaning quality of electrolytic cleaning tanks, increasing the time for stopping production to process plates, and reducing the cleaning quality of strip steel, etc. Achieve the effects of solving the decline in strip cleaning quality, improving cleaning efficiency and cleaning quality, and solving the problem of stopping production and dealing with a large workload of plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

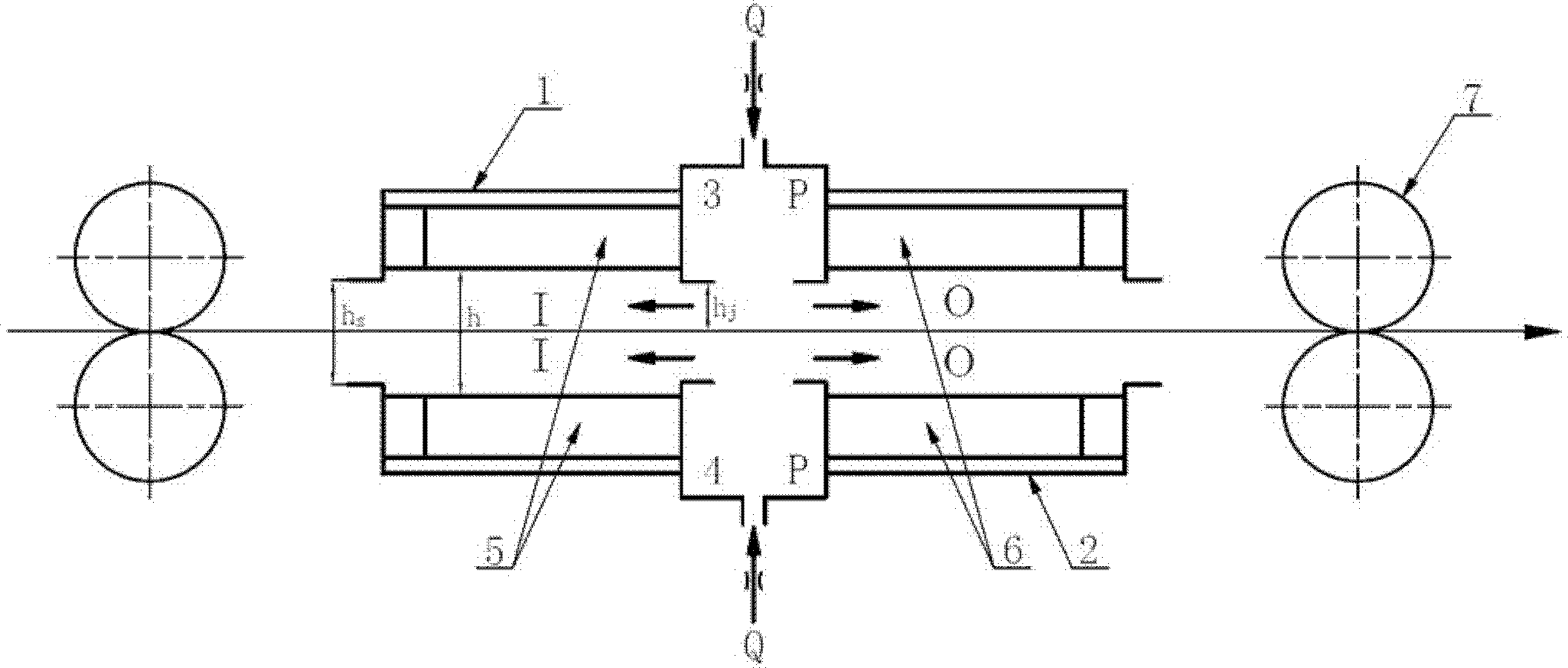

[0009] Embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing: figure 2 The shown electrolytic cleaning tank adopts the method of not changing the polarity of the intermediate conductor on the pole plate. Its structure is mainly composed of upper tank body 1, lower tank body 2, upper static pressure chamber 3, lower static pressure chamber 4, anode plate 5, and cathode plate 6. Composed of squeeze rollers 7, the entrance cleaning area I is located from the entrance of the electrolytic cleaning tank to the left edge of the upper and lower static pressure chambers, and the outlet cleaning area O is located from the exit of the electrolytic cleaning tank to the right side of the upper and lower static pressure chambers edge; the height of the entrance and exit of the electrolytic cleaning tank is hs, and the value of hs is less than the distance h between the upper and lower electrode plates; hj. is the distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com