Patents

Literature

86results about How to "Improve anti-PID performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar cell with composite dielectric passivation layer structure and preparation process thereof

PendingCN110459615AIncrease short circuit currentIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationDielectricRefractive index

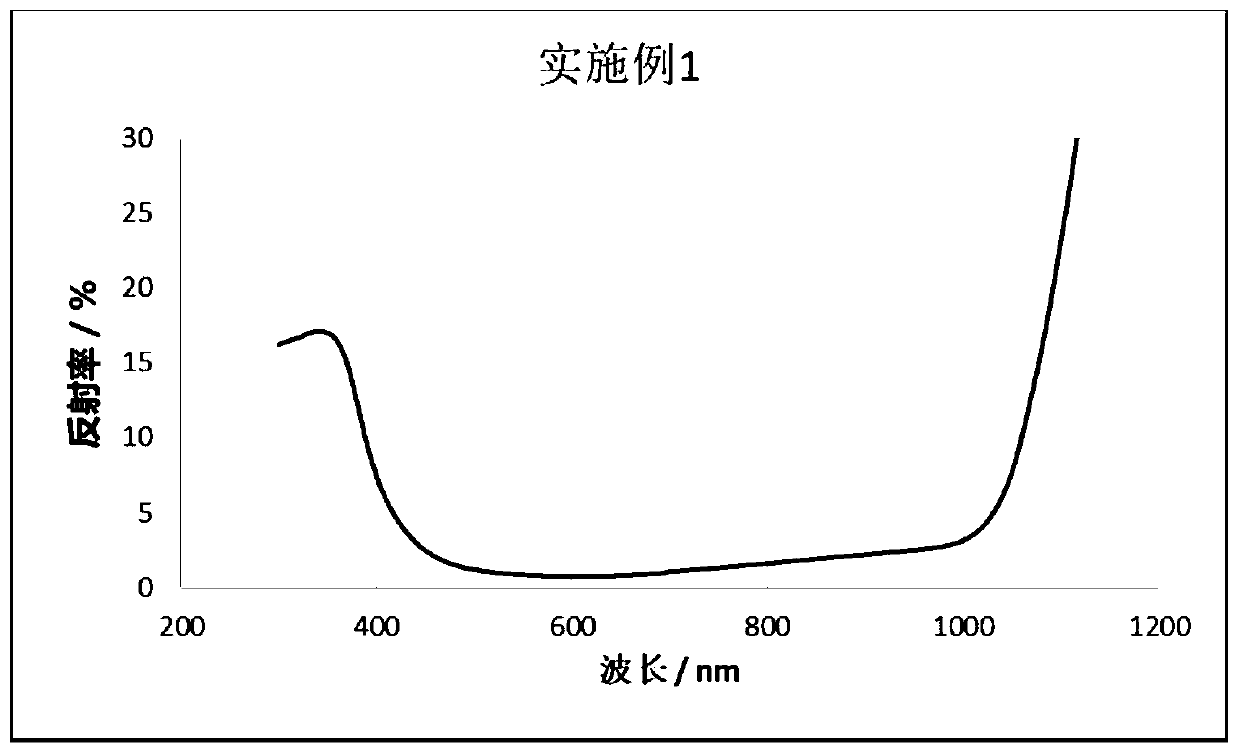

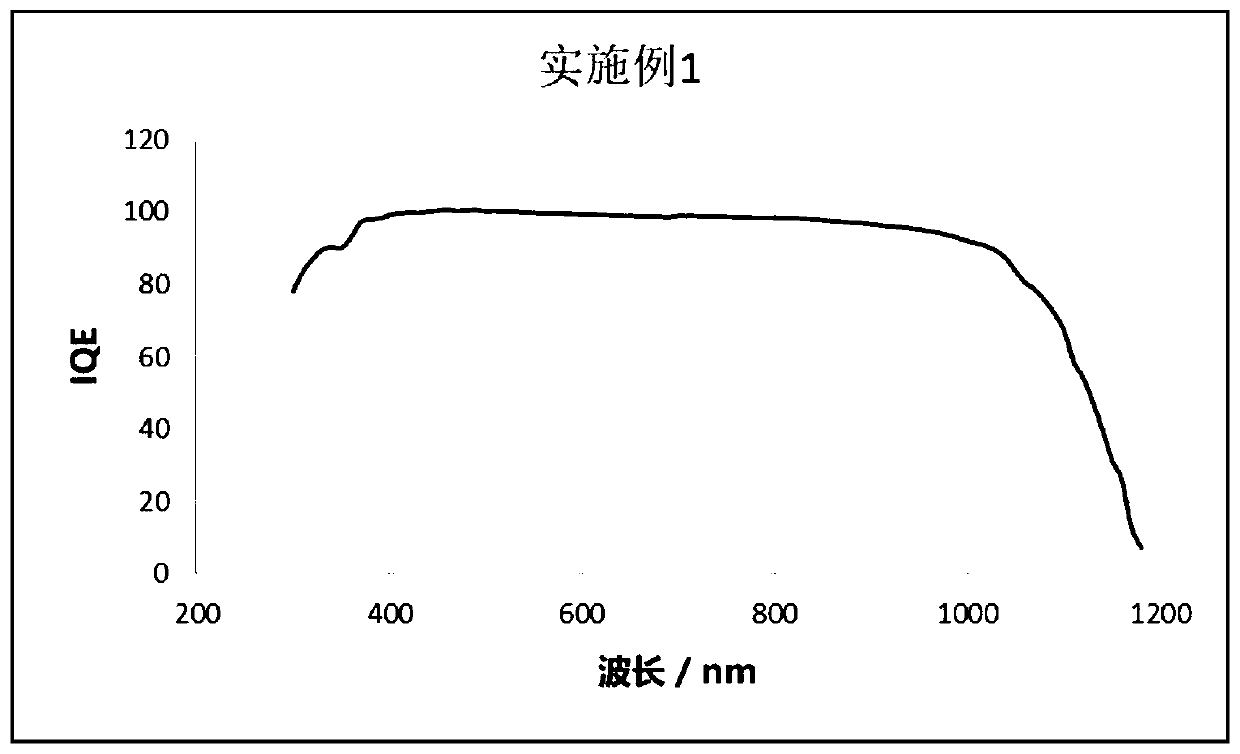

The invention discloses a solar cell with a composite dielectric passivation layer structure and a preparation process thereof. A silicon oxide film, an alumina film and a silicon nitride or silicon oxynitride film are deposited in turn on the front, back and sides of a p-type silicon substrate to form a composite dielectric film on the whole surface, and windows are opened locally to lead electrodes out. Through aluminum oxide, silicon dioxide, silicon oxynitride, silicon nitride with different refractive indexes and a back surface passivation layer with a laminated structure of the materials, the back surface recombination rate is greatly reduced, the back reflectivity is improved, the CTM of a module is reduced, and the light attenuation and heat-assisted light attenuation and the anti-PID performance of the cell are improved. The structure can be made on a boron / gallium-doped p-type monocrystalline silicon, p-type polycrystalline silicon or p-type monocrystalline-silicon-like substrate, and a passivation method based on the composite dielectric film passivation structure can be used to manufacture PERC cells, double-sided PERC+ cells and imbricate PERC cells. Based on the preparation process steps and sequence, the corresponding preparation mode and the process parameter range of the laminated structure, the making of the cell can be well completed.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID +2

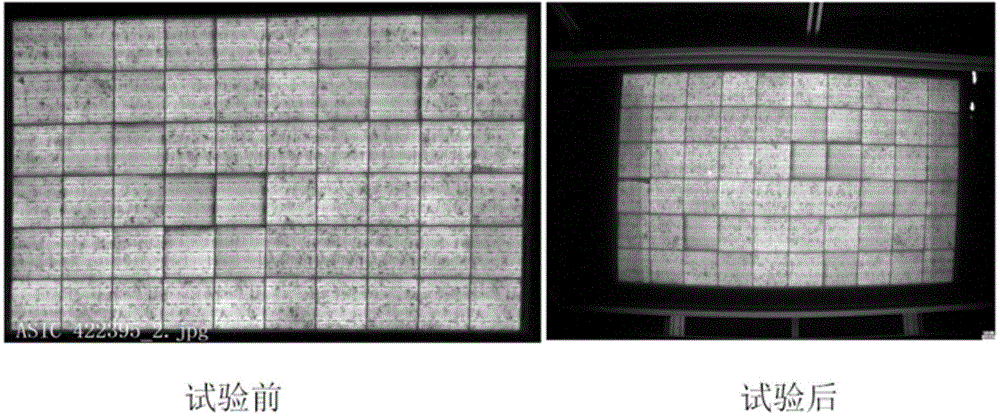

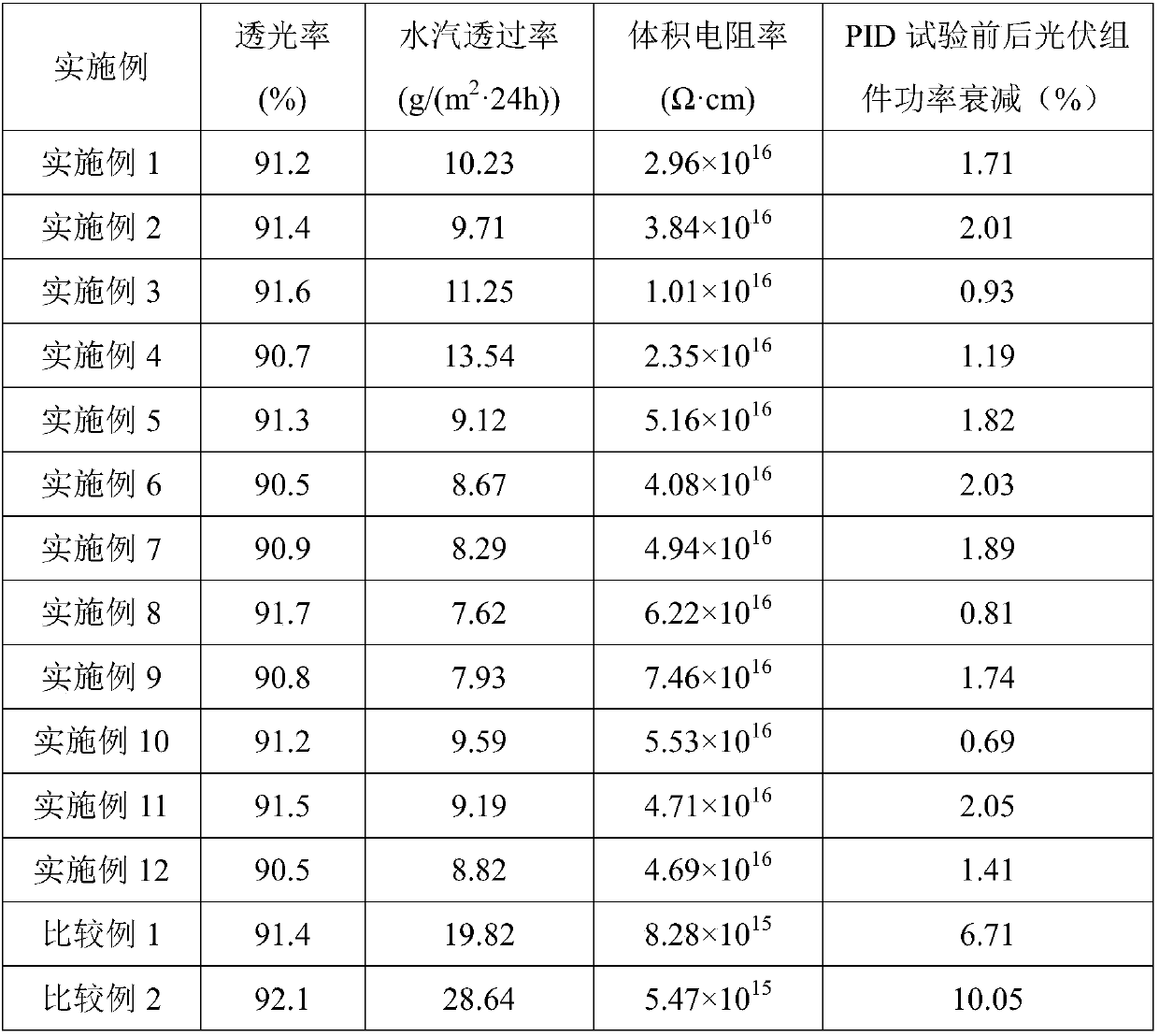

Anti-PID (potential induced degradation) polyolefin adhesive film for solar cell module

InactiveCN105950039ALow water vapor transmission rateHigh volume resistivityNon-macromolecular adhesive additivesFilm/foil adhesivesPotential induced degradationPolyolefin

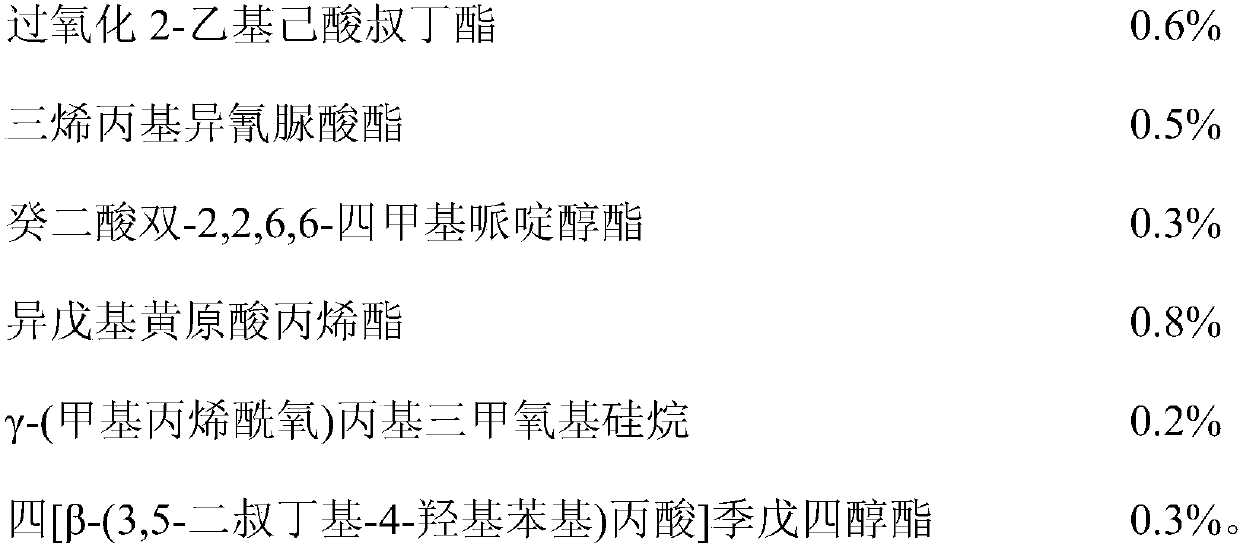

The invention discloses an anti-PID (potential induced degradation) polyolefin adhesive film for a solar cell module. The anti-PID adhesive film is an A / B / A three-layer film; the mass ratio of three layers A, B and A is (10-20):(60-80):(10-20); the layer B of adhesive film is a copolymer of ethylene and alpha-olefin; the DSC (differential scanning calorimetry) melting point of the layer B of adhesive film is higher than 90 DEG C. The anti-PID polyolefin adhesive film has the advantages that the permeation rate of water vapor is lower, the volume resistivity is higher, and the solar cell module has better anti-PID property; by matching with the outer layer A of the adhesive film, the crosslinking property, adhering property and flexibility of low-melting point polyolefin resin composition, and the heat-resistant property, blocking property and electric insulation property of high-melting point polyolefin resin composition are also realized.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

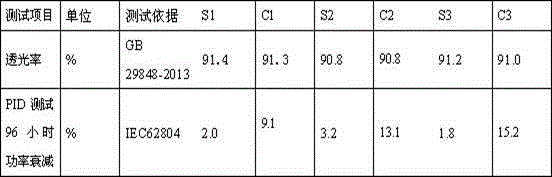

PID-resistant encapsulation adhesive film used for photovoltaic cell

ActiveCN104530994ANo hydrolysis reactionCohesive solutionNon-macromolecular adhesive additivesFilm/foil adhesivesPolyolefinAlpha-olefin

The invention discloses a PID-resistant encapsulation adhesive film used for a photovoltaic cell. The PID-resistant encapsulation adhesive film comprises, by mass, polyolefin resin 80%-95%, polyhedral oligomeric silsesquioxane 1%-20%, a peroxide crosslinking agent 0.1-2%, an auxiliary crosslinking agent 0.01-1%, a light stabilizing agent and an ultraviolet absorber, wherein the polyolefin resin is an ethylene / alpha-olefin copolymer or a composition of the ethylene / alpha olefin copolymer; the polyhedral oligomeric silsesquioxane contains a hydrolysable radical which is selected from one or more of a methoxy group, an ethoxy group, a methoxyethoxy group and an acetoxyl group. The PID-resistant encapsulation adhesive film has good adhesive performance and ageing-resistant performance while having excellent PID-resistant performance, thereby having positive practical significance.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

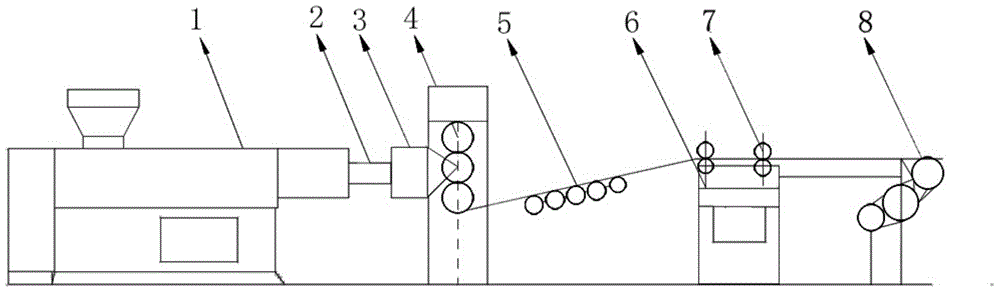

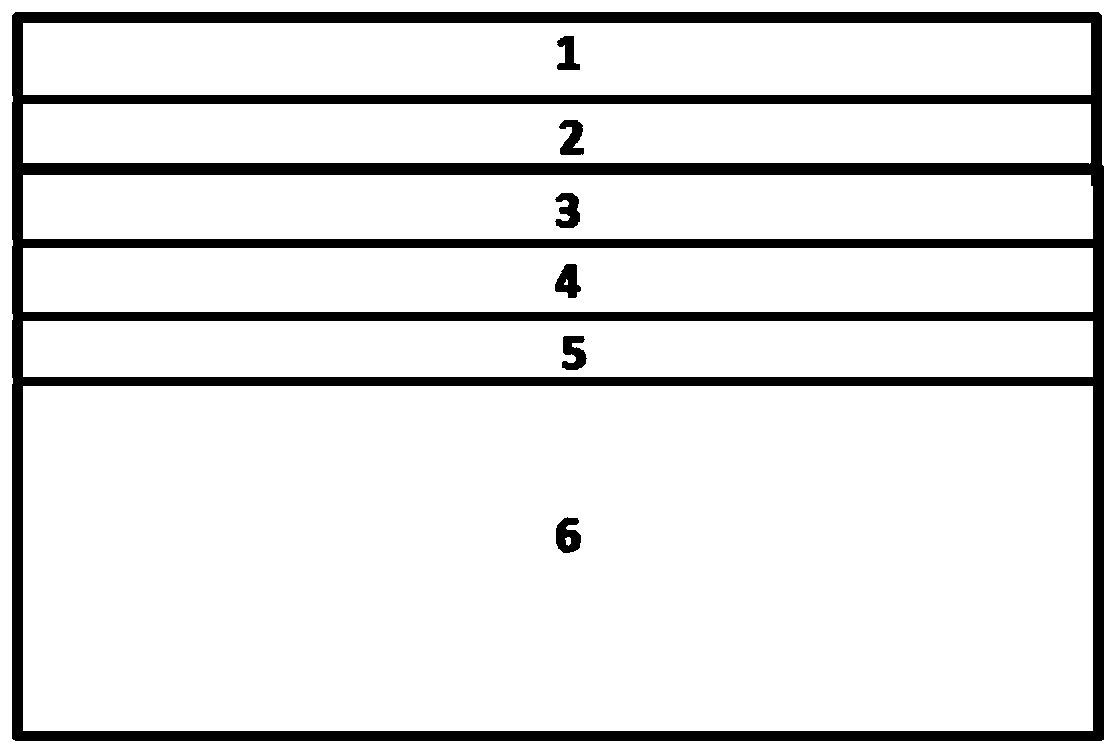

Multi-layer packaging material used for solar module and preparation technology and device thereof

InactiveCN104538471AReduce manufacturing costIncrease productivitySynthetic resin layered productsElectrical equipmentColloidal particleBackplane

The invention discloses a multi-layer packaging material used for a solar module. The multi-layer packaging material is composed of a POE surface layer A, an EVA core layer B and a POE surface layer C in sequence. The POE surface layer A is an adhesive film, and is made of ethylene and POE colloidal particles, and the surface of the POE surface layer A makes contact with a solar battery piece. The EVA core layer B is made of EVA polymers and performance additives. The POE surface layer C is an adhesive film, and is made of ethylene and POE colloidal particles, and the surface of the POE surface layer A makes contact with a back board in the solar module. The ageing-resistant performance of the material is high.

Owner:CHANGZHOU JIUHE NEW ENERGY

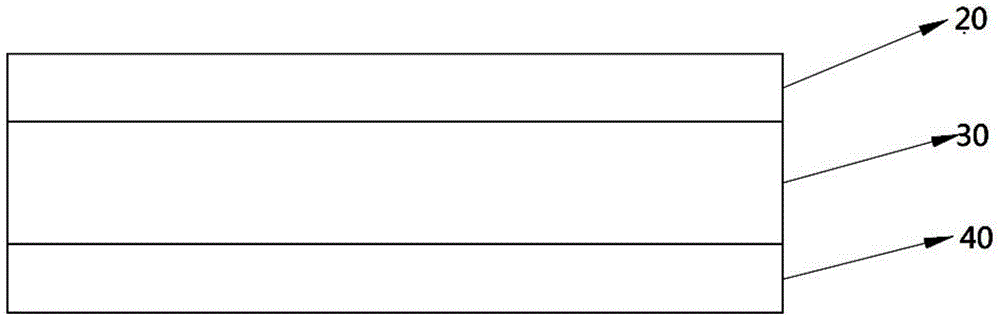

Three-layer co-extrusion composite adhesive film for packaging photovoltaic module and preparation method thereof

PendingCN111793442AGood compatibilitySolve the bubblesNon-macromolecular adhesive additivesFilm/foil adhesives without carriersPolymer scienceTransmittance

The invention relates to the technical field of photovoltaic module packaging adhesive films, in particular to a three-layer co-extrusion composite adhesive film for packaging a photovoltaic module and a preparation method thereof. The composite adhesive film comprises EVA layers, a POE anti-polarization layer and an EVA layer which are sequentially arranged from top to bottom, wherein EVA resin has a melt flow rate of 5 g / 10 min-30 g / 10 min, light transmittance of larger than 85%, volume resistivity of larger than or equal to 1.0 * 10<14>, melting temperature of 30-80 DEG C, and VA content of5-30%; POE resin has a melt flow rate of 3 g / 10 min-20 g / 10 min, light transmittance of greater than 86%, volume resistivity of greater than or equal to 1.0 * 10<15> and melting temperature of 30-80DEG C. The EVA layers are adopted on the two sides of the composite adhesive film, the compatibility of the EVA layers and polar auxiliaries is good, and the problems of bubbles, slippage and piece combining during assembly laminating can be solved.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Solar cell multi-layer anti-reflection grading film and preparation method thereof

PendingCN110391304ALow refractive indexHigh refractive indexFinal product manufactureChemical vapor deposition coatingRefractive indexSilicon oxide

The invention discloses a solar cell multi-layer anti-reflection grading film and a preparation method thereof. The solar cell multi-layer anti-reflection grading film comprises a first silicon nitride film, a second silicon nitride film, a first silicon oxynitride film, a second silicon oxynitride film and a silicon oxide film which are arranged in order from bottom to top, and the refractive index of each film is reduced layer by layer from bottom to top. The solar cell multi-layer anti-reflection grading film is formed by the two layers of silicon nitride films, the two layers of oxynitridefilms and a layer of the silicon oxide film, the refractive index of each film is reduced layer by layer, the problem is solved that the difference of the refractive indexes between the current silicon nitride films is large to cause the light loss due to optical mismatch, the whole refractive index of the front surface of the solar cell is lower, the light absorption is increased, and the conversion efficiency of the solar cell is improved; and moreover, the refractive index of the silicon nitride film at the inner layer is large, the silicon nitride film has an excellent passivation effectto further enhance the short-wave response of the solar cell and improve the anti-PID performance of the solar cell.

Owner:TIANJIN AIKO SOLAR ENERGY TECH CO LTD

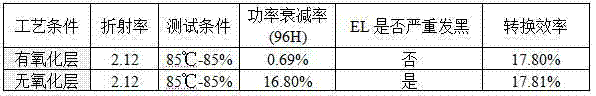

Low-pressure oxidation technology for solar cell

ActiveCN107681018AReduce pressureStable airflowFinal product manufacturePhotovoltaic energy generationPower flowEngineering

The invention discloses a low-pressure oxidation technology for a solar cell, and the technology mainly comprises the steps: preprocessing, reaction preparation, oxidation reaction, cooling and annealing, and boat withdrawing. A silicon dioxide film generated through the technology in a low-pressure environment where the temperature is less than 800 DEG C prolongs the service life of a few of carriers, and finally increases a short-circuit current and an open-circuit voltage of the cell, thereby improving the photoelectric conversion efficiency. A low-pressure diffusion furnace, compared witha normal pressure diffusion furnace, is small in pressure intensity, and is stable in air flow, thereby enabling the structure of the generated silicon dioxide film to be more compact and uniform. Theprepared silicon dioxide film is better in PID resistance.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

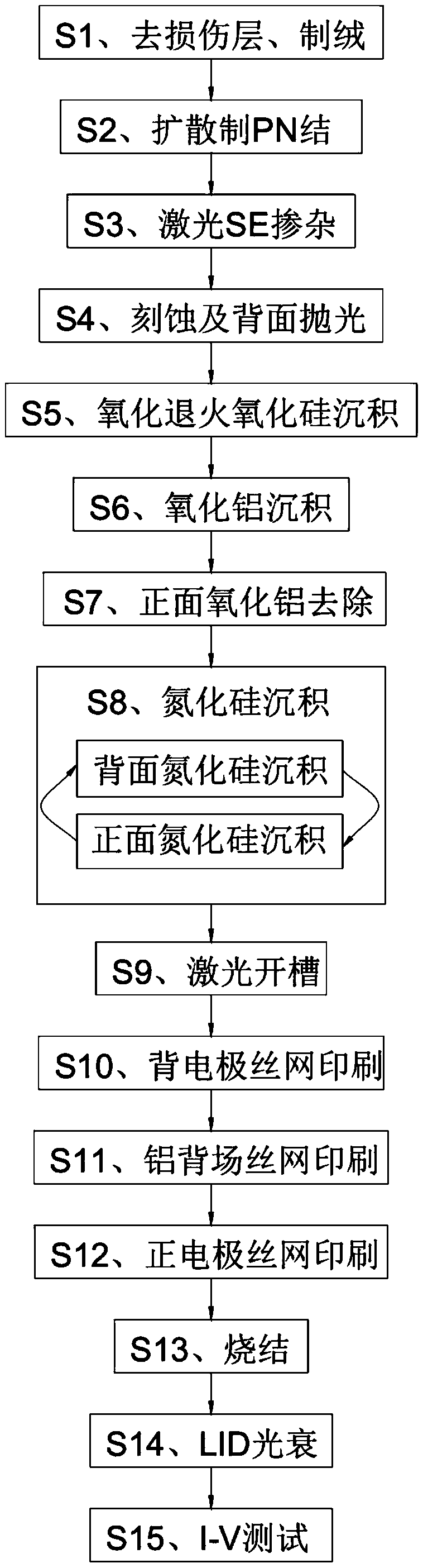

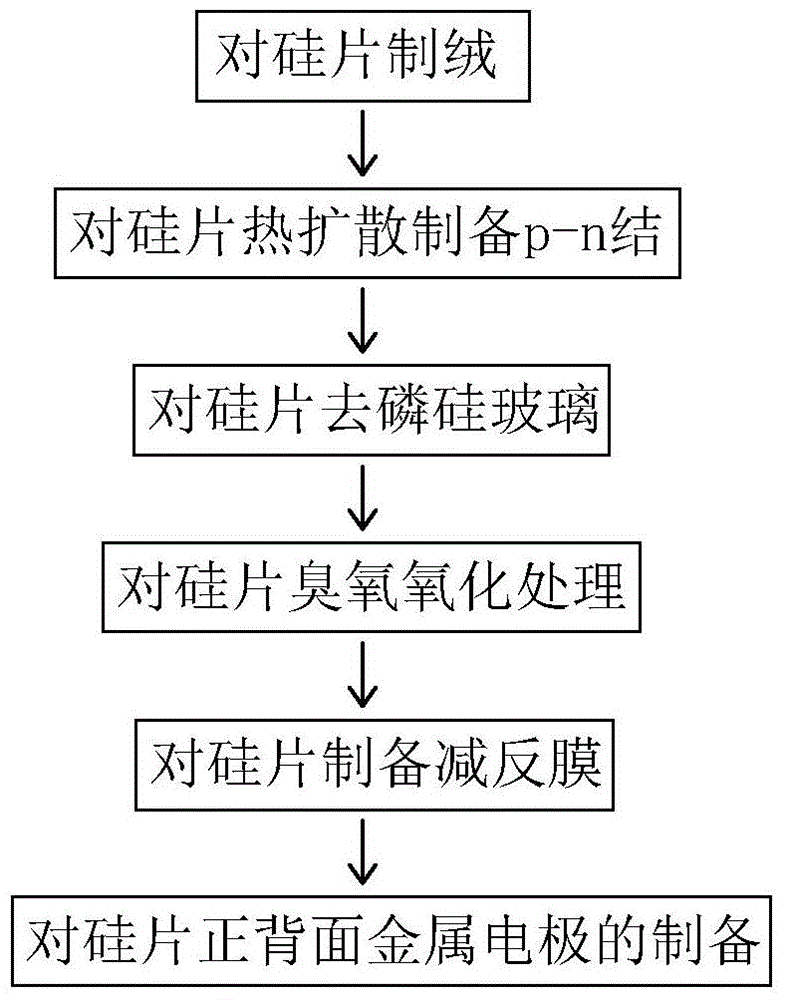

Method for preparing anti-potential induced degradation solar cell

ActiveCN104821345AImprove yield rateImprove anti-PID performanceFinal product manufacturePhotovoltaic energy generationPotential induced degradationScreen printing

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD +1

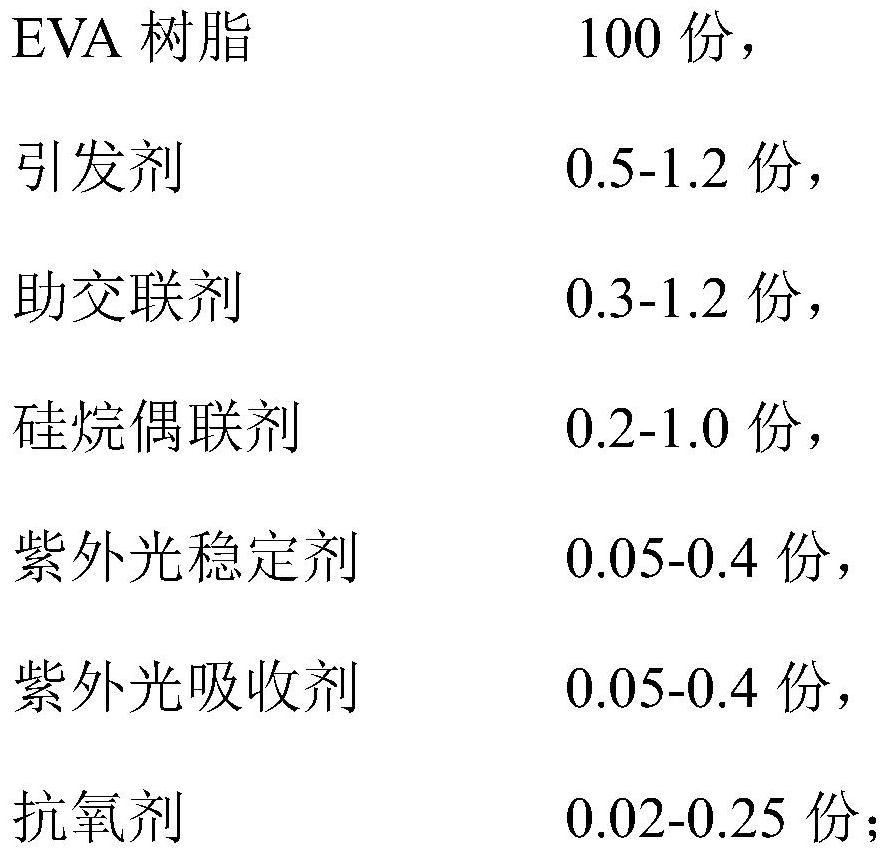

EVA adhesive film for encapsulating solar cell and preparing process of EVA adhesive film

ActiveCN104861886AGood water vapor barrierTransmittance is not affectedNon-macromolecular adhesive additivesFilm/foil adhesivesAcetic acidTransmittance

The invention discloses an EVA adhesive film for encapsulating a solar cell and a preparing process thereof. The EVA adhesive film is mainly characterized in that polyacrylamide is added into raw material components, the polyacrylamide is used as an acid-absorbing water repellent, and a small quantity of free acetic acid in EVA and acid micromolecular substances generated in the ageing process are effectively eliminated or neutralized, so that the encapsulating adhesive film has excellent vapor blocking performance. As the adopted polyacrylamide is nanoscale granules or powder and does not influence the light transmittance of the adhesive film basically, the PID resistance of the assembly is effectively improved.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

Photovoltaic encapsulation material EVA adhesive film resisting potential induced attenuation

ActiveCN108034372AImprove anti-PID performanceHigh volume resistivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesLow-density polyethyleneWater vapor

The invention discloses a photovoltaic encapsulation material EVA adhesive film resisting potential induced attenuation. EVA with the VA content being 8 to 21wt percent and low-density polyethylene orvinyl copolymer with the melting rang being 70 to 130 DEG C are mixed into matrix resin; then the matrix resin, complex absorbing sodium ion and other assistants are subjected to premixing, melt extrusion, casting and film formation, cooling, slitting and rolling processes, so that the adhesive film is formed. The ion mobility is reduced through proper reducing of the VA content, the improvementof the volume resistivity of the EVA adhesive film and the reducing of the content of acetic acid in a photovoltaic system from the source. The volume resistivity of the EVA adhesive film is improvedthrough the adding of the high-melting polyethylene or vinyl copolymer, and meanwhile water vapor transmittance is reduced. Environment of sodium ion on the surface of a battery is reduced through theadding of the complex absorbing sodium ion, passivation phenomenon caused in a battery piece antireflection layer is weakened or even eliminated, and the potential induced attenuation resistance of the adhesive film is improved.

Owner:福斯特(滁州)新材料有限公司

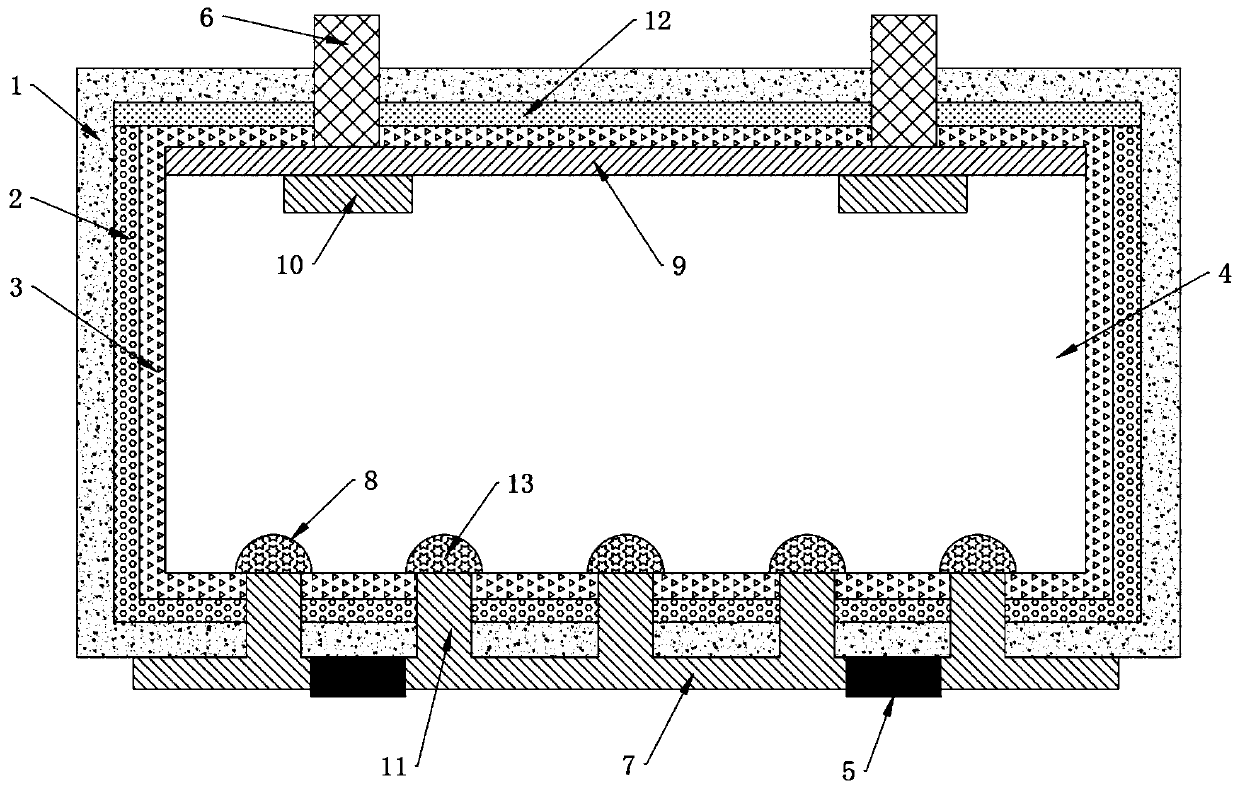

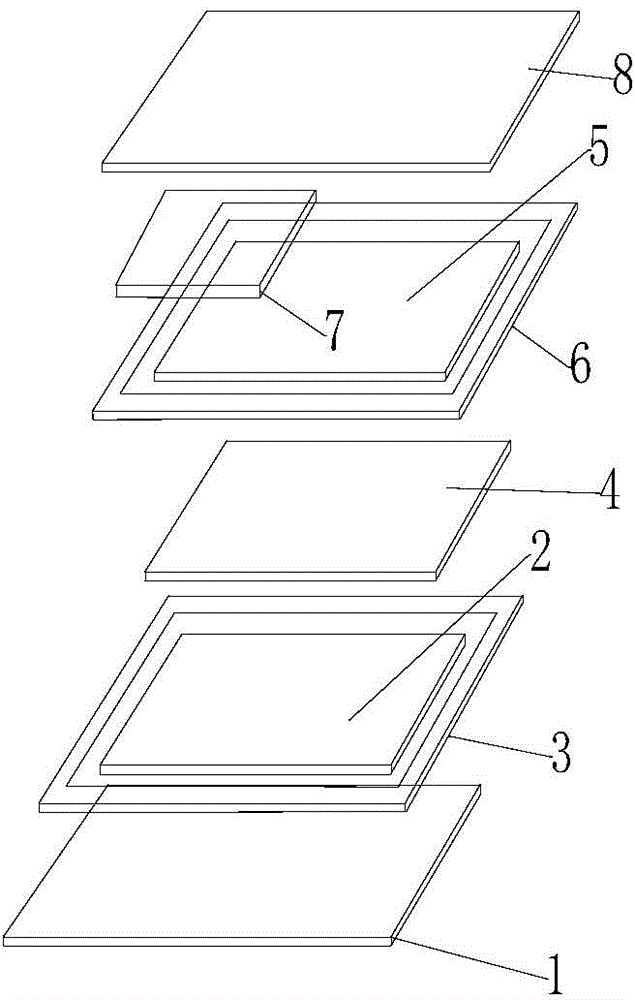

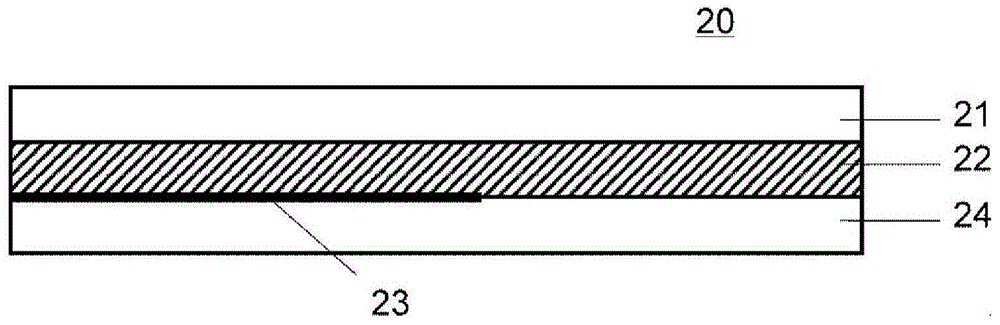

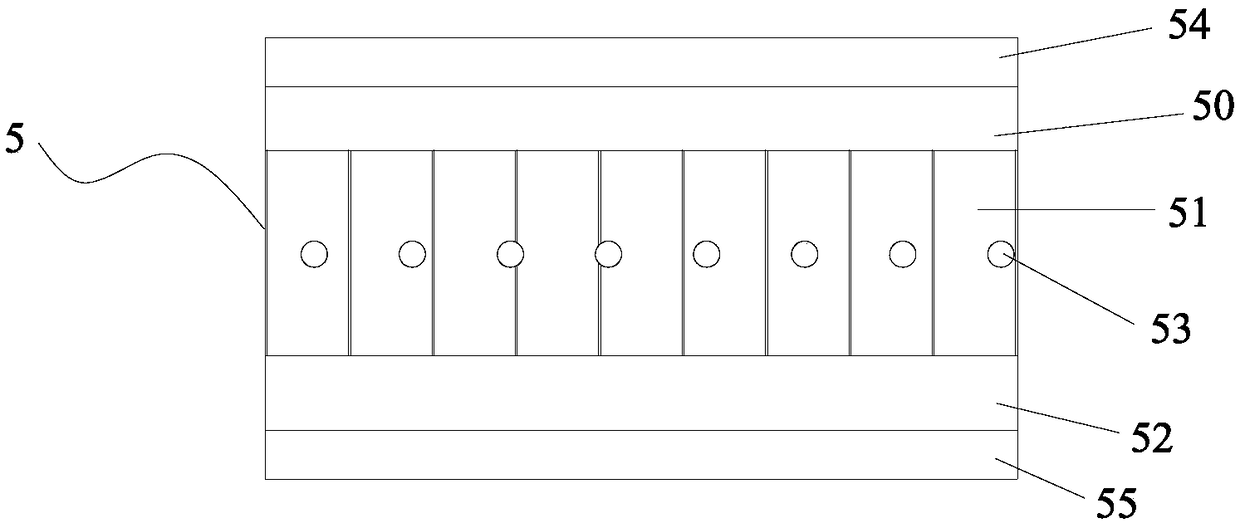

Anti-PID (potential Induced Degradation) photovoltaic module

ActiveCN104966743AAvoid PID phenomenaImprove anti-PID performancePhotovoltaic energy generationSemiconductor devicesPotential induced degradationEngineering

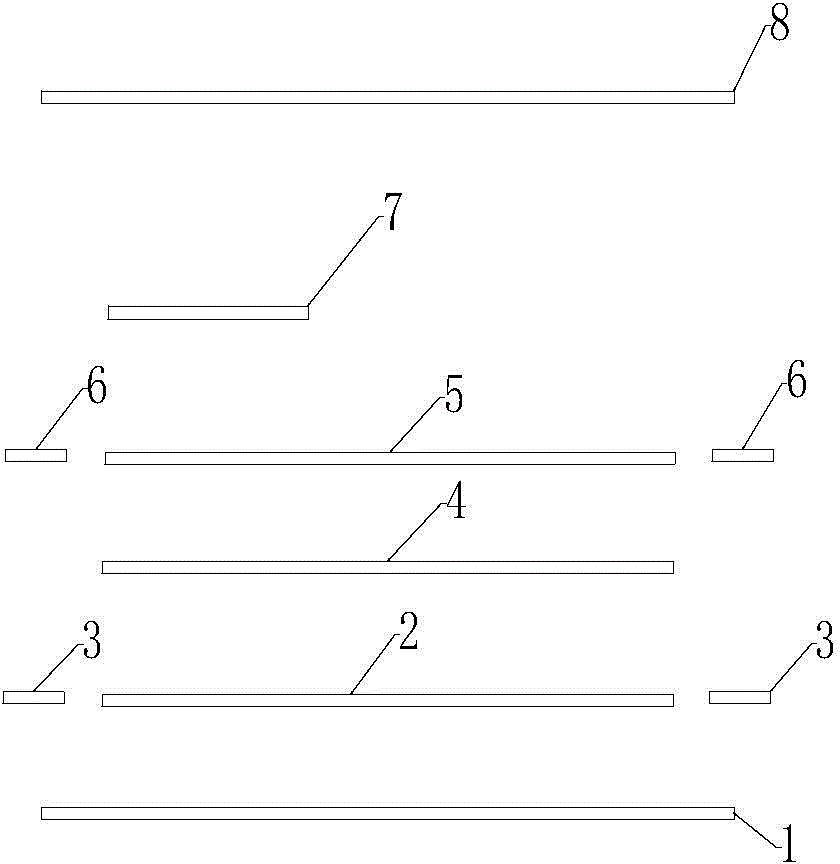

The invention provides an anti-PID (potential Induced Degradation) photovoltaic module, which comprises an ultra clear glass layer, a first anti-PID packaging layer, a first EVA film layer, a solar cell layer, a second anti-PID packaging layer, a second EVA film layer, a third anti-PID packaging layer and a backplane layer overlapped sequentially from bottom to top, wherein both the first anti-PID packaging layer and the second anti-PID packaging layer have a box structure; the first EVA film layer is located in the first anti-PID packaging layer and the first anti-PID packaging layer is packaged around the first EVA film layer; the second anti-PID packaging layer is located in the second EVA film layer and the second anti-PID packaging layer is packaged around the second EVA film layer; the third anti-PID packaging layer is overlapped on the second EVA film layer; and the third anti-PID packaging layer is laid at the position of a leading-out wire of the backplane layer. The above anti-PID photovoltaic module has good anti-PID performance.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

Water-based environment-friendly white glaze for high-reflection anti-PID photovoltaic backboard glass and preparation method of water-based environment-friendly white glaze

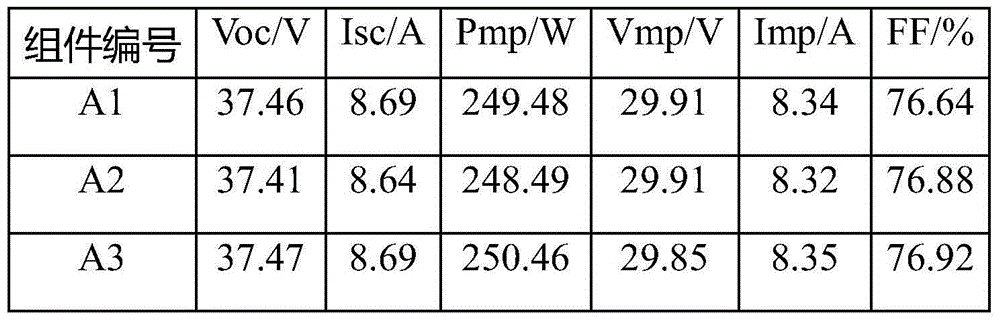

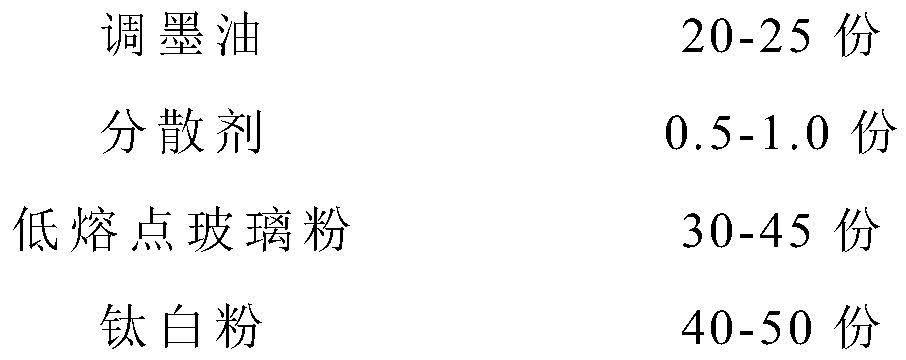

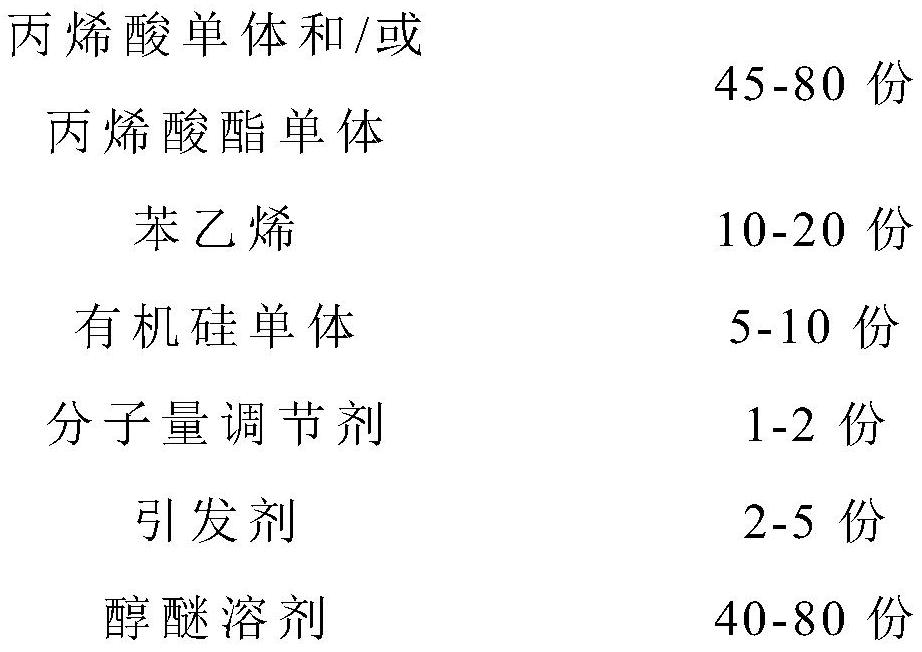

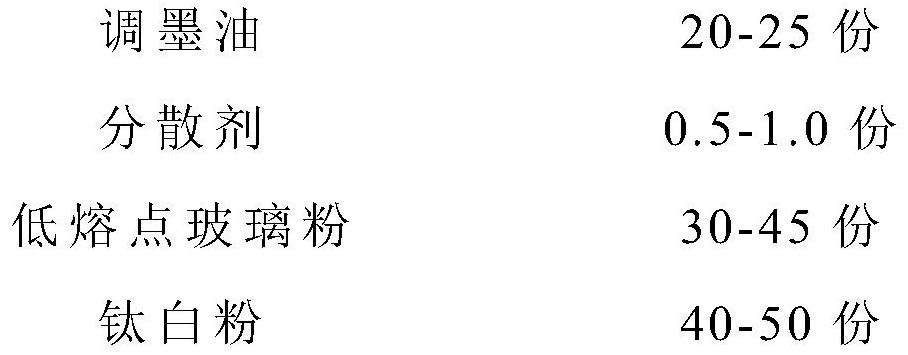

The invention discloses a water-based environment-friendly white glaze for high-reflection anti-PID photovoltaic backboard glass and a preparation method and application of the water-based environment-friendly white glaze. The water-based environment-friendly white glaze is composed of varnish, a dispersing agent, low-melting-point glass powder, titanium dioxide, a flatting agent and a defoaming agent, and the water-based environment-friendly white glaze has the high reflectivity (larger than or equal to 78%) on visible light and resists PID (potential-induced degration). The softening temperature of the low-melting-point glass powder is 450-550 DEG C, the total melting temperature of the low-melting-point glass powder is 520-560 DEG C, so that the water-based environment-friendly white glaze is completely molten within a short time within the tempering temperature range of 600-720 DEG C, the linear expansion coefficient of the low-melting-point glass powder is 80-85 * 10 <-7 > / K (30-300 DEG C) and is close to that of matrix glass, and the stress between the low-melting-point glass powder and the matrix glass is close in the cooling process; and the adhesive force of a glaze layer and the dimensional stability of glazed glass are ensured. The titanium dioxide is prepared through a chlorination method, the impurity content is extremely low, silicon oxide and aluminum oxide are used for coating treatment, lattice defects caused by titanium dioxide under the ultraviolet irradiation condition can be blocked, light activation points on the surface of titanium dioxide can be shielded, and the PID resistance is improved.

Owner:WUJIANG CSG GLASS CO LTD +1

Manufacturing method of anti-PID battery piece and photovoltaic component

ActiveCN106328723AIncreasing the thicknessImprove compactnessPhotovoltaic energy generationSemiconductor devicesSiliconMixed gas

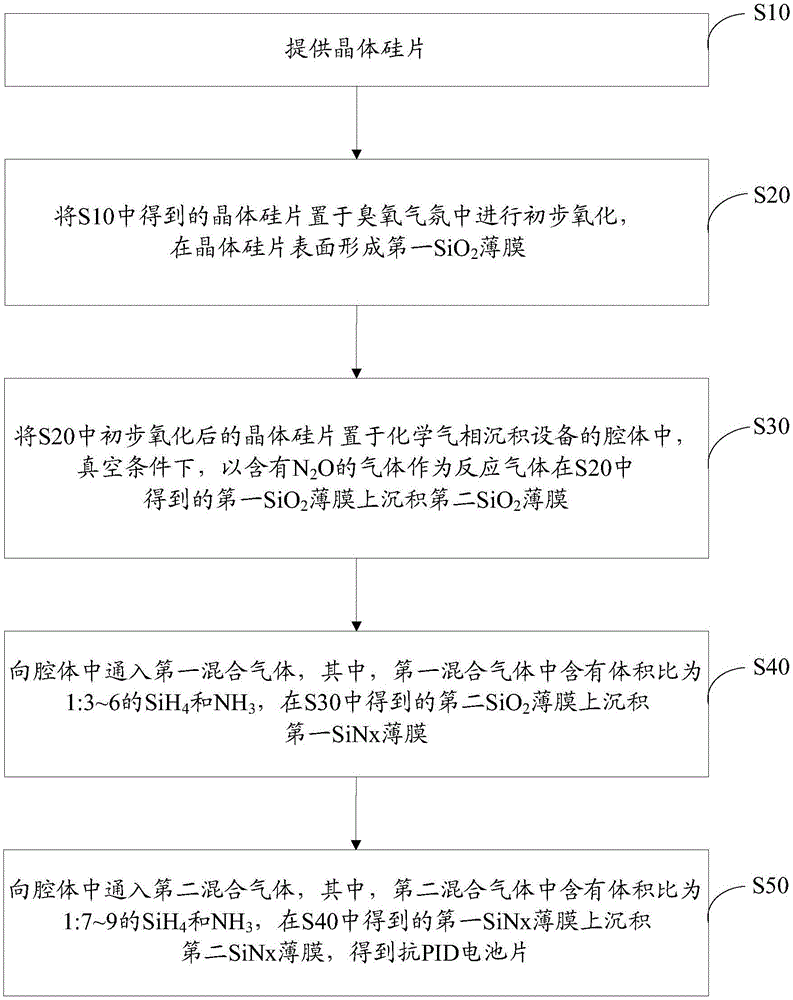

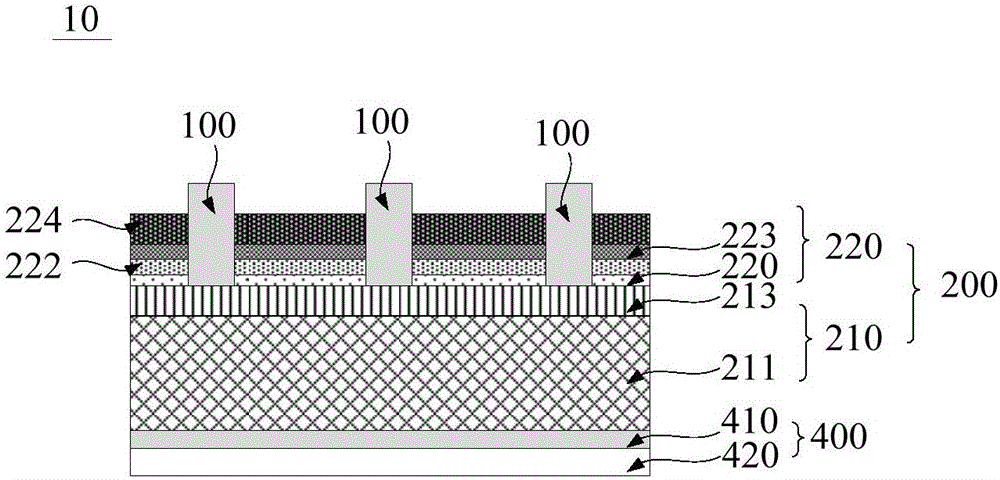

The invention relates to a manufacturing method of an anti-PID battery piece and a photovoltaic component. The manufacturing method includes: putting a crystal silicon wafer in an ozone atmosphere for primary oxidation to form a first SiO2 thin film; using gas containing N2O as reaction gas to deposit a second SiO2 thin film on the first SiO2 thin film; depositing a first SiNx thin film in first mixed gas and a second SiNx thin film in second mixed gas. The second SiO2 thin film can make up incomplete coverage of primary oxidation and can increase thickness and compactness of a SiO2 film layer. Cooperation between the first SiNx thin film and the second SiNx thin film can enhance absorption of the surface of the battery piece to ultraviolet short waves. By the method, the battery piece is high in compactness of the film layer, more continuous in interface and good in anti-PID performance.

Owner:CSG PVTECH +1

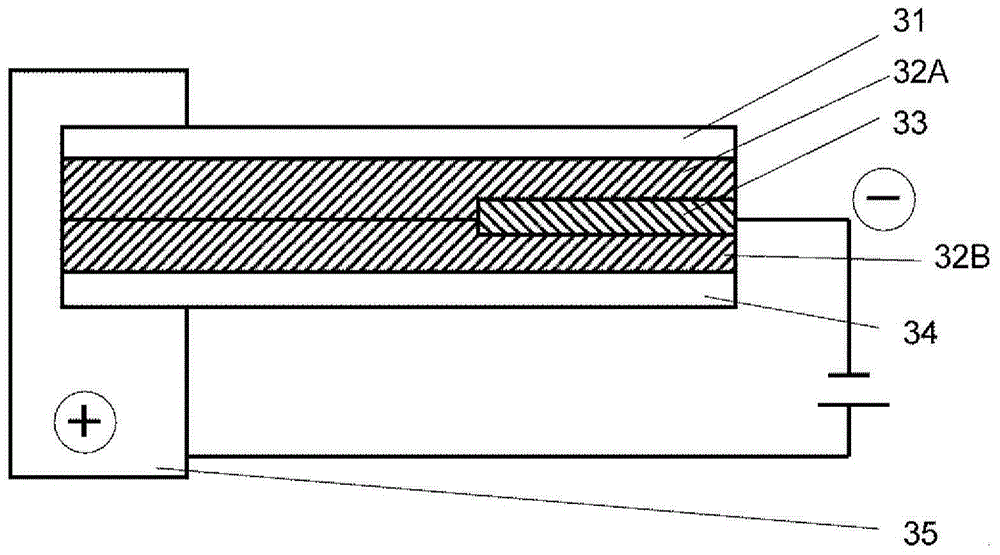

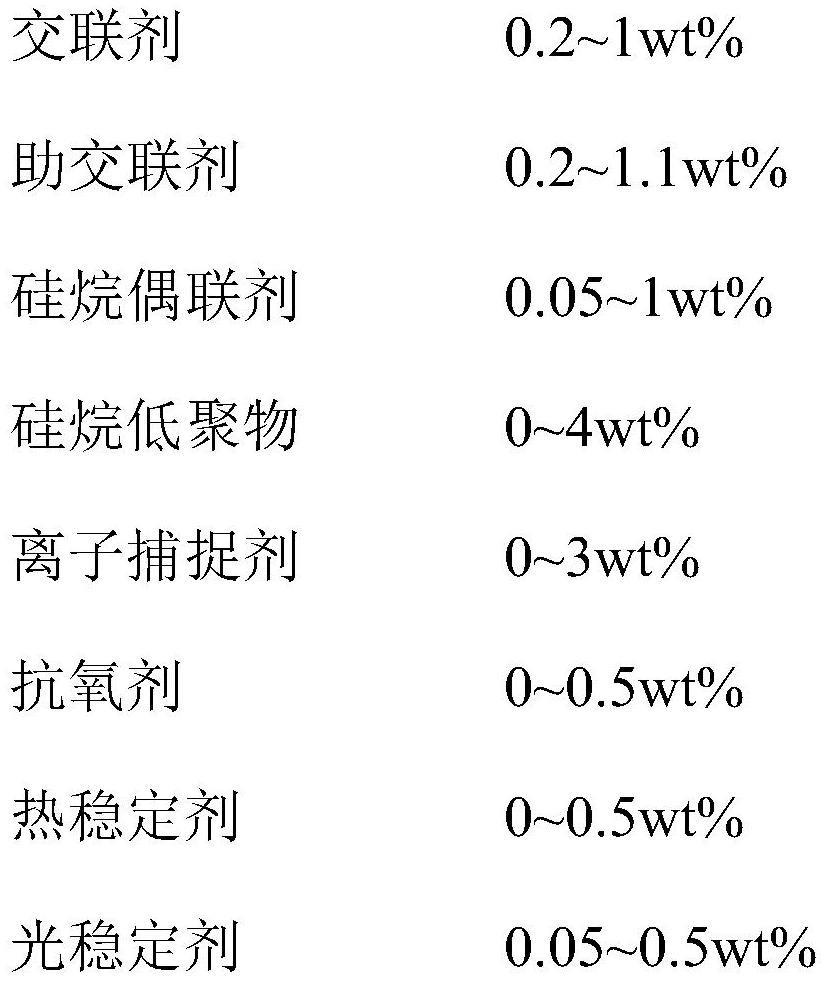

Anti-PID photovoltaic EVA packaging film and preparation method thereof

ActiveCN107841256AGuaranteed anti-PID performanceOvercoming polarity reductionNon-macromolecular adhesive additivesFilm/foil adhesives without carriersIonDamp heat

The invention provides an anti-PID photovoltaic EVA packaging film and a preparation method thereof. The EVA packaging film is prepared from EVA resin and the following raw materials: based on the mass of the EVA resin, 0.5 to 0.8% of a main cross-linking agent, 0.4 to 0.6% of an auxiliary cross-linking agent, 0.2 to 0.5% of a light stabilizing agent, 0.3 to 1.2% of an ion capturing agent, 0.1 to0.5% of a coupling agent and 0.1 to 0.5% of an anti-oxidant. The EVA packaging film prepared in the invention has volume resistivity of no less than 1016 omega.cm and shrinkage of no more than 0.5%; after testing under the conditions of a temperature of 85 DEG C and relative humidity of 85% for 2000 h, the EVA packaging film has a damp-heat aging yellowing value of no more than 2.5 and an ultraviolet aging yellowing value of no more than 2.5; and the EVA packaging film has good PID resistance, reliability and stability.

Owner:CSI SOLAR POWER GROUP CO LTD +1

Resin composition for solar cell sealing materials, master batch for solar cell sealing materials, and solar cell sealing material

ActiveCN105009305AGood dispersionHigh transparencyOther chemical processesPhotovoltaic energy generationPhosphatePhosphoric acid

The purpose of the present invention is to provide a resin composition for solar cell sealing materials, which is capable of forming a solar cell sealing material with good resistance to PID, while having good transparency and suppressing decrease of adhesion to a light receiving surface-side protection glass even after long-term use. A resin composition for solar cell sealing materials according to the present invention contains an ethylene copolymer and an inorganic ion scavenger. The inorganic ion scavenger contains one or more compounds that are selected from the group consisting of oxides of pentavalent metals, oxides of hexavalent metals, oxides of heptavalent metals and metal phosphate salts. This resin composition for solar cell sealing materials contains 0.01-0.5 part by weight of the inorganic ion scavenger per 100 parts by weight of the ethylene copolymer.

Owner:TOYO INK SC HOLD CO LTD +1

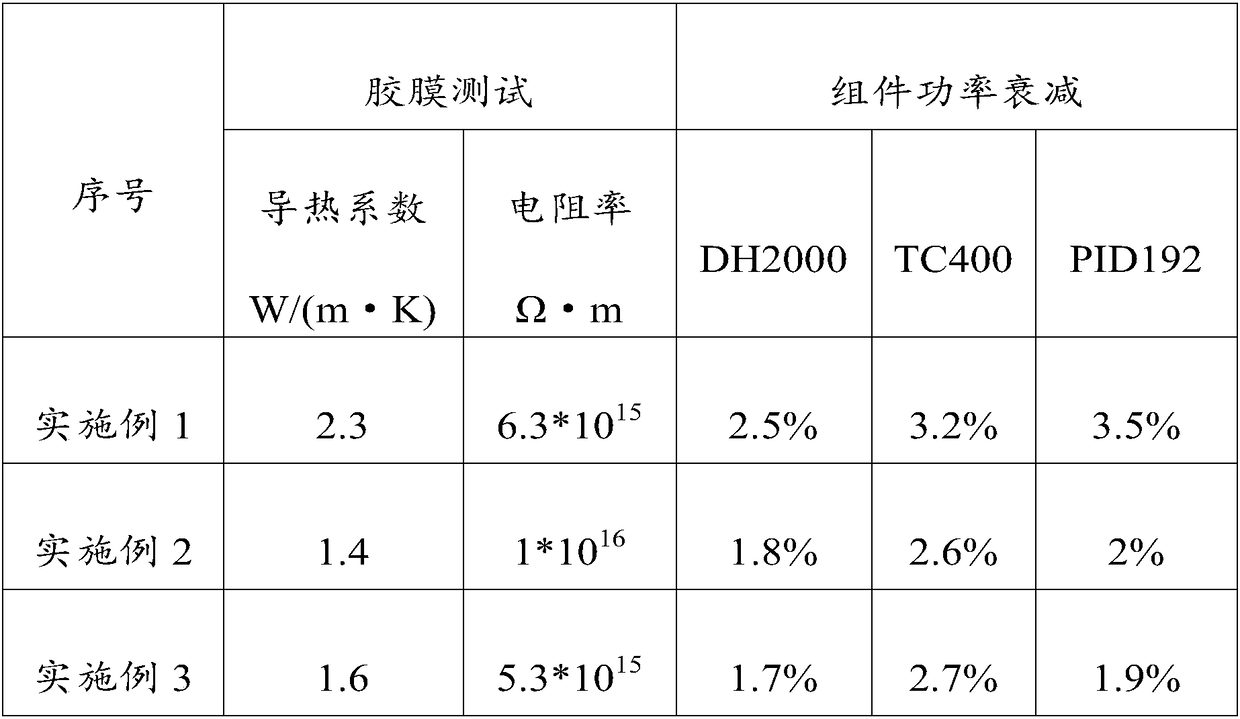

Anti-PID heat conduction glue film, photovoltaic assembly and photovoltaic power generation system

ActiveCN109321148AReduce light transmittanceImprove reflectivityNon-macromolecular adhesive additivesFilm/foil adhesives without carriersPhotovoltaic power generationBackplane

The invention relates to an anti-PID heat conduction glue film, a photovoltaic assembly and a photovoltaic power generation system, and belongs to the technical field of photovoltaics. The anti-PID heat conduction glue film comprises a glue film body and core-shell particles doped in the glue film body; each core-shell particle comprises an insulation inorganic heat conduction material inner coreand a protection outer shell coated at the outer surface of the insulation inorganic heat conduction material inner core. The photovoltaic assembly comprises the anti-PID heat conduction glue film; the anti-PID heat conduction glue film is bonded between a backboard of the photovoltaic assembly and a battery of the photovoltaic assembly. The photovoltaic power generation system comprises a plurality of photovoltaic assemblies in series connection and / or parallel connection arrangement. Insulation and heat conduction core-shell particles are doped in the glue film body and can be stably dispersed in the glue film for a long time. When the photovoltaic assembly is locally shielded or works at high irradiation, the core-shell particles can realize fast heat absorption or heat radiation; the battery temperature is reduced; the assembly output power is improved. Meanwhile, the core-shell particles have good insulation performance; the current passage channel can be isolated; the volume resistivity of the glue film is improved; the anti-PID performance of the assembly is greatly improved.

Owner:CECEP SOLAR ENERGY TECH (ZHENJIANG) CO LTD

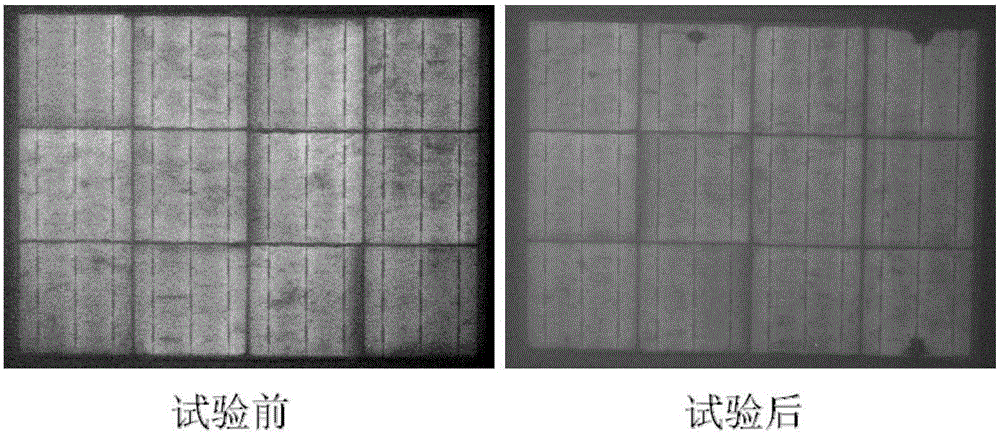

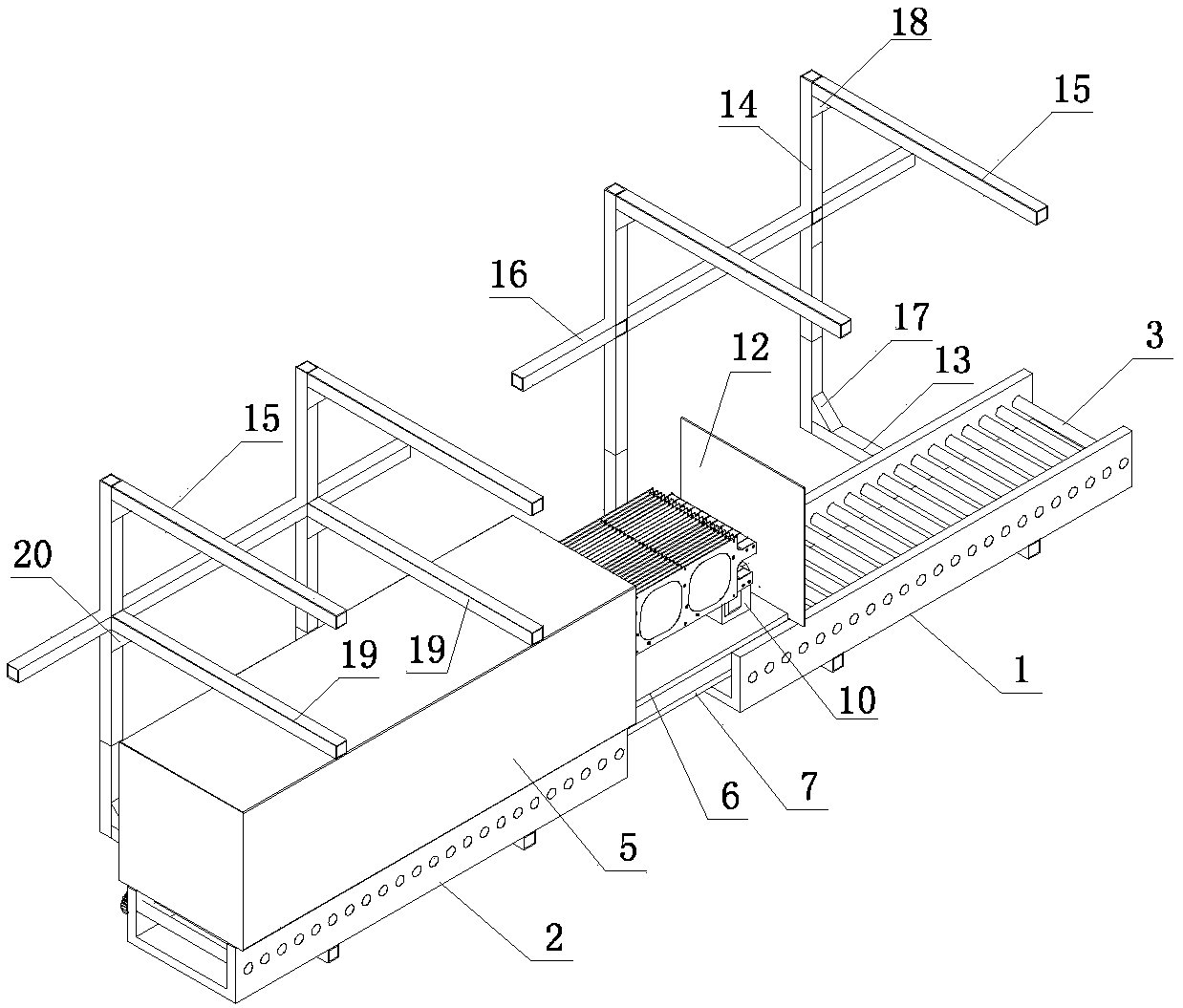

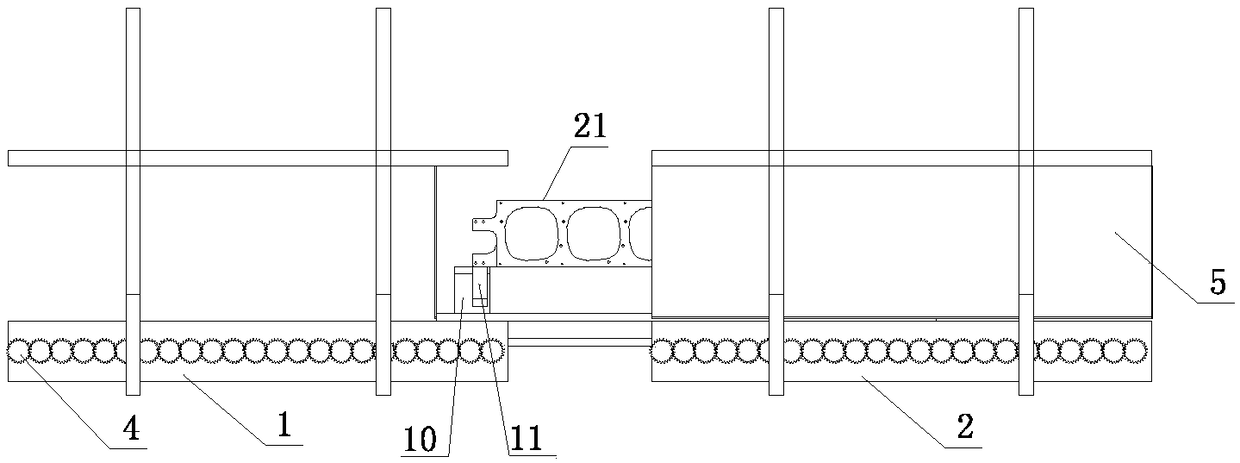

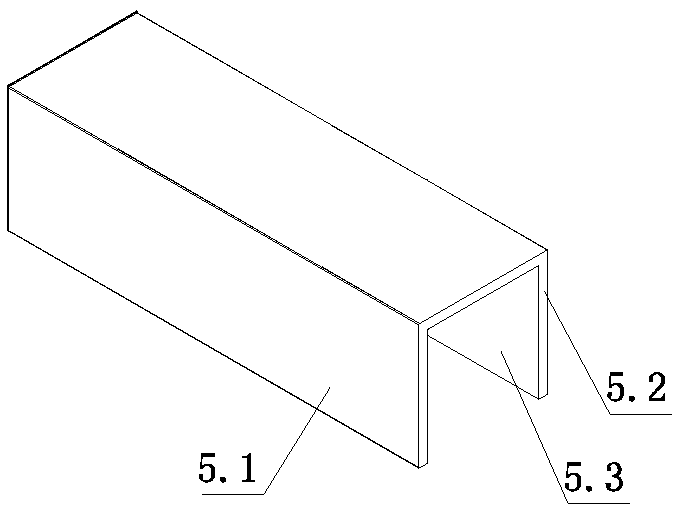

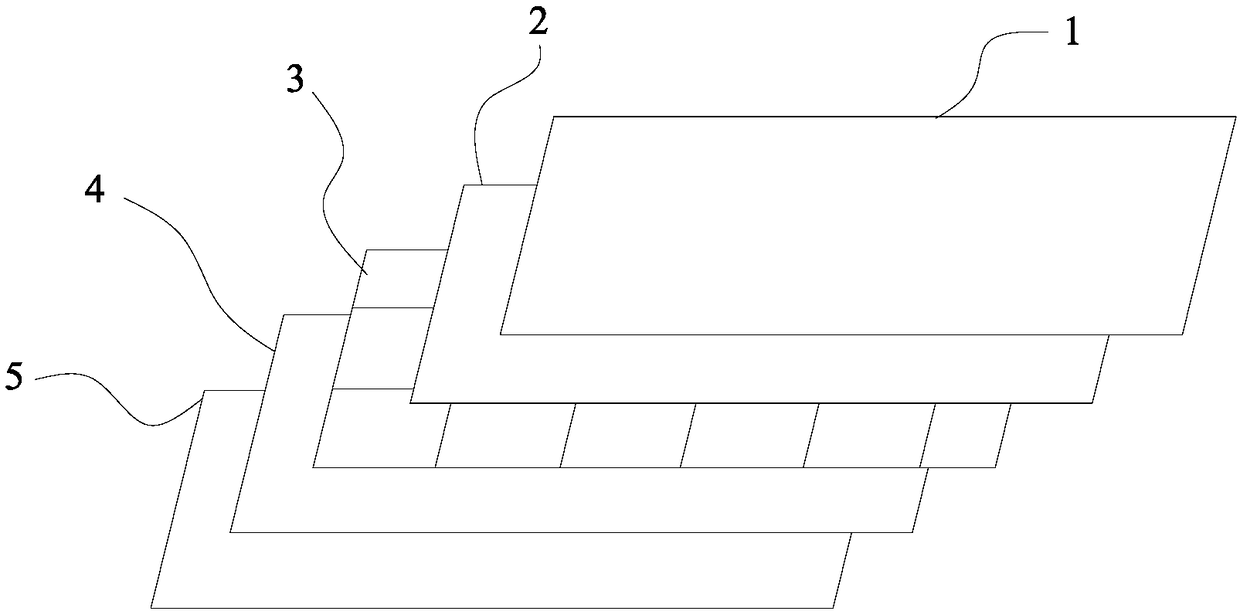

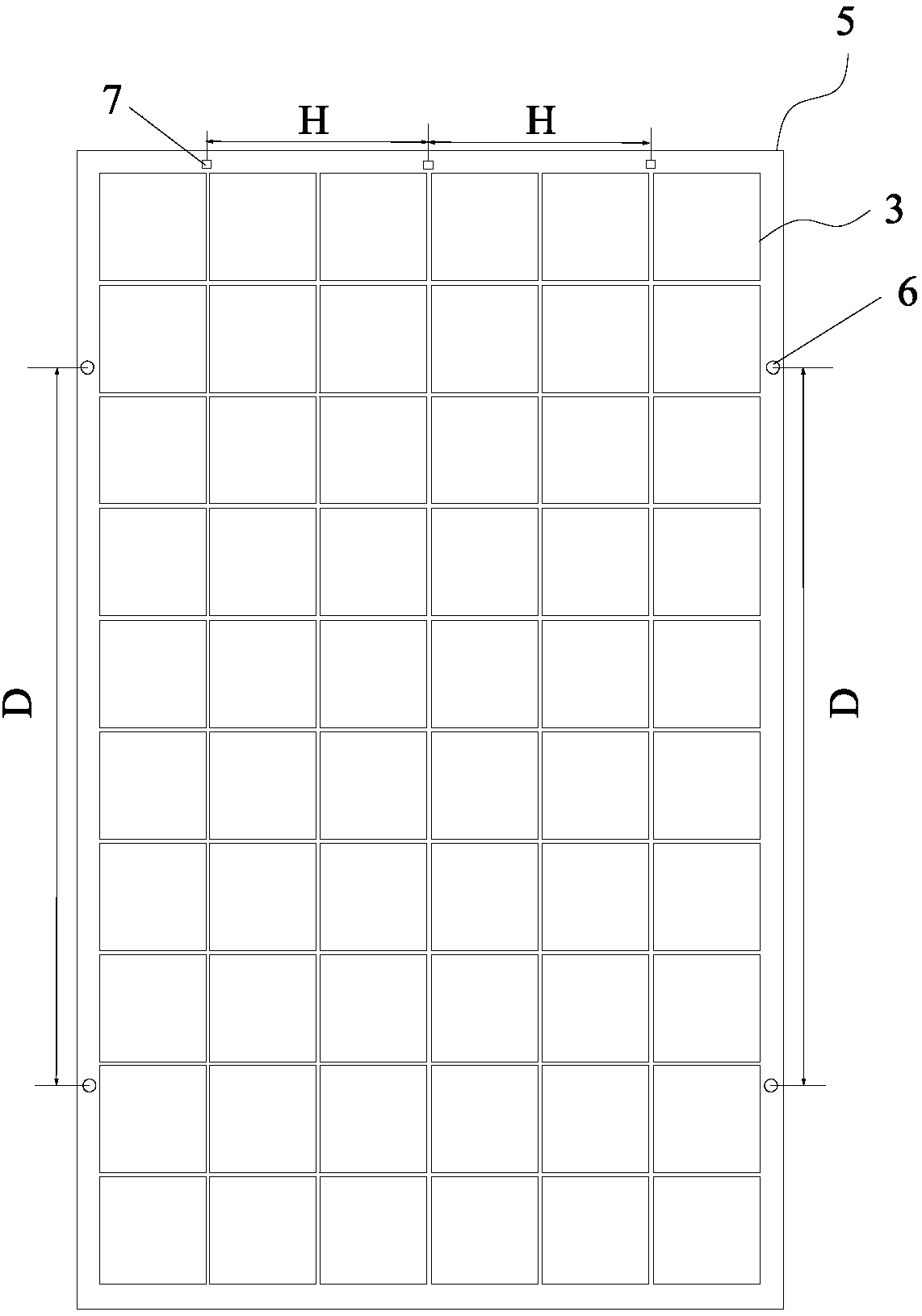

Tubular PECVD storage boat preheating device for crystalline silicon solar cell and coating method

ActiveCN108950514AImprove passivation effectImprove anti-PID performanceChemical vapor deposition coatingGraphiteEngineering

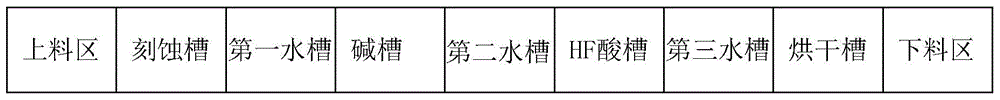

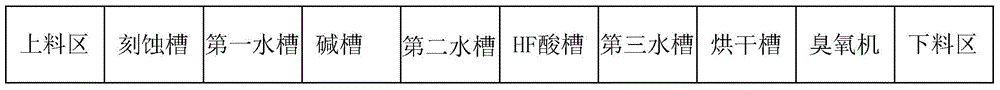

The invention relates to a tubular PECVD storage boat preheating device for a crystalline silicon solar cell and a coating method. According to the storage boat preheating device, an original storageboat frame is omitted, a transmission rail A and a transmission rail B are additionally arranged on a position of the original storage boat frame and are on the same straight line of the original storage boat frame, a storage boat preheating box is arranged right above the transmission rail B, and a transmission tray slides between the two rails. During operation, the transmission tray is firstlypositioned on the rail A, a mechanical arm loads a graphite boat to the transmission tray, the transmission tray carries the graphite boat to be conveyed to the rail B and loaded into the storage boatpreheating box; the graphite boat is preheated in the box during the time period of waiting for an empty tube, and meanwhile, oxygen in the air is used for oxidizing a silicon wafer, so that the ozone oxidation process at an etching blanking position can be omitted; and when the empty tube is available, the transmission tray and the graphite boat are conveyed to the rail A and then enter the empty tube for coating. Due to the fact that the graphite boat is preheated and oxidized in advance, an original heating step is omitted in coating process, the whole process period in the tube is shortened by about 13.7 minutes, and yield is increased by 50%.

Owner:WUXI SUNTECH POWER CO LTD

Light photovoltaic module

ActiveCN109390422AReduce usagePrevent precipitationLayered productsSemiconductor devicesInsulation layerEngineering

The present invention relates to a light photovoltaic module. The light photovoltaic module comprises a transparent front plate, a first package layer, a solar cell, a second package layer and a backplate which are arranged in order in a stack mode. The back plate comprises a first substrate layer, a honeycomb core layer and a second substrate layer which are arranged in order in a stack mode, the first substrate layer and the honeycomb core layer and the second substrate layer and the honeycomb core layer are spliced by employing adhesion agents, the first substrate layer is located betweenthe second package layer and the honeycomb core layer, the first substrate layer is a resin insulation layer or a metal layer, when the first substrate layer is the metal layer, the light photovoltaicmodule further comprises a first insulation layer arranged between the second package layer and the first substrate layer. The back plate of the light photovoltaic module employs a back plate with aporous honeycomb structure to allow the light photovoltaic module to be light in weight, to be easy to install, to meet the high-load requirement and to extend the module application range, and therefore, the light photovoltaic module has larger advantages on the application of large-scale projects such as a distributed power station project.

Owner:CYBRID TECHNOLOGIES INC

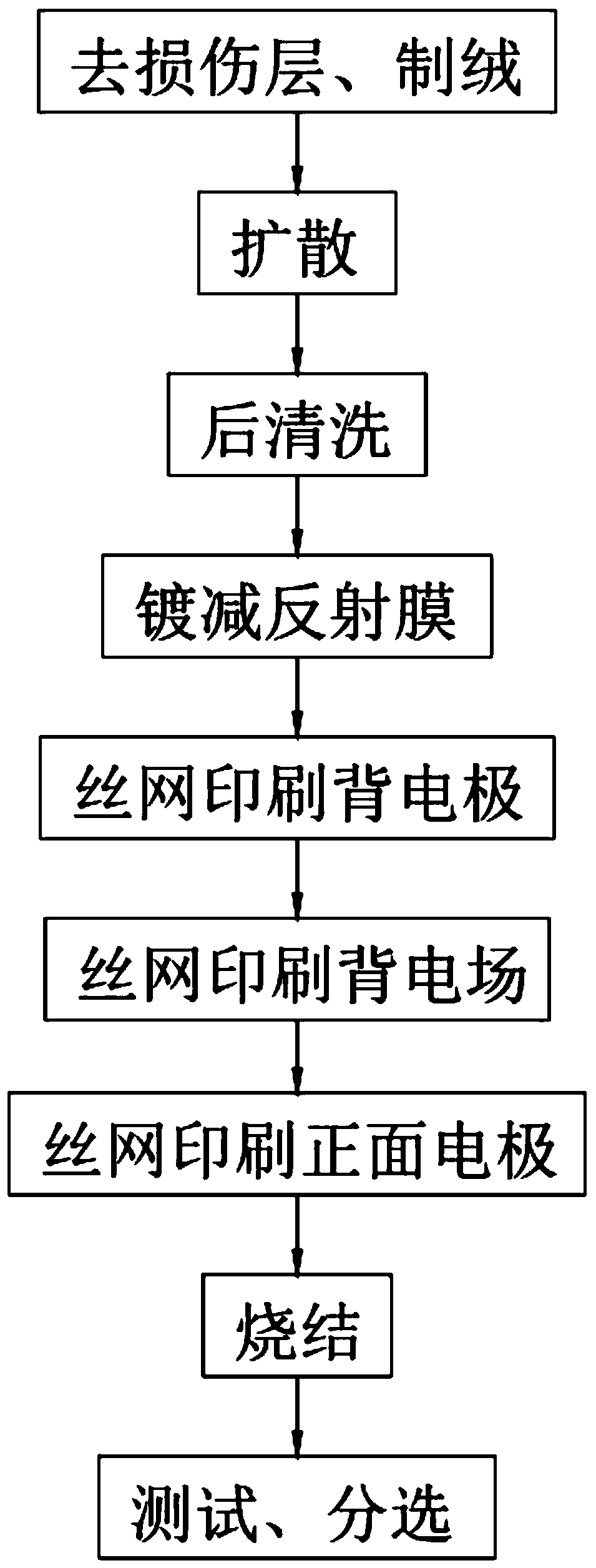

Method for preparing PID-resisting film

InactiveCN103943718AImprove passivation effectReduce lossesFinal product manufacturePhotovoltaic energy generationEngineeringSilicon oxide

The invention discloses a method for preparing a PID-resisting film. The method includes the following steps that a crystal silicon wafer is selected, after texturing and diffusing are performed, double layers of films of a silicon oxide film and a silicon nitride film or a silicon oxynitride film and a silicon nitride film are sequentially generated on a light receiving face of the crystal silicon wafer. The silicon oxide film is deposited in an ultraviolet photosensitized oxidation mode or a PECVD mode, silicon nitride or silicon oxynitride is deposited in a PECVD mode, silicon oxide or the silicon oxynitride located at a bottom layer has the blocking action on foreign ions, the passivation effect is good, the silicon nitride film located on a top layer is combined, losses of the photoelectric conversion efficiency of solar cell pieces can be reduced, and the PID-resisting performance of the solar cell pieces can be enhanced.

Owner:JA SOLAR TECH YANGZHOU

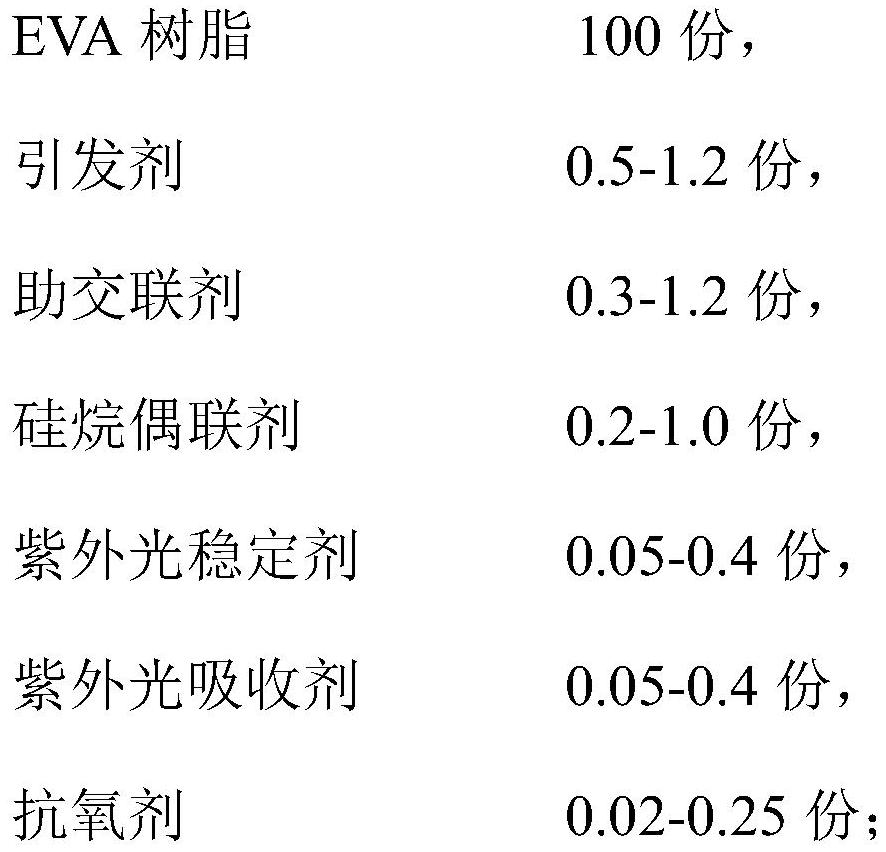

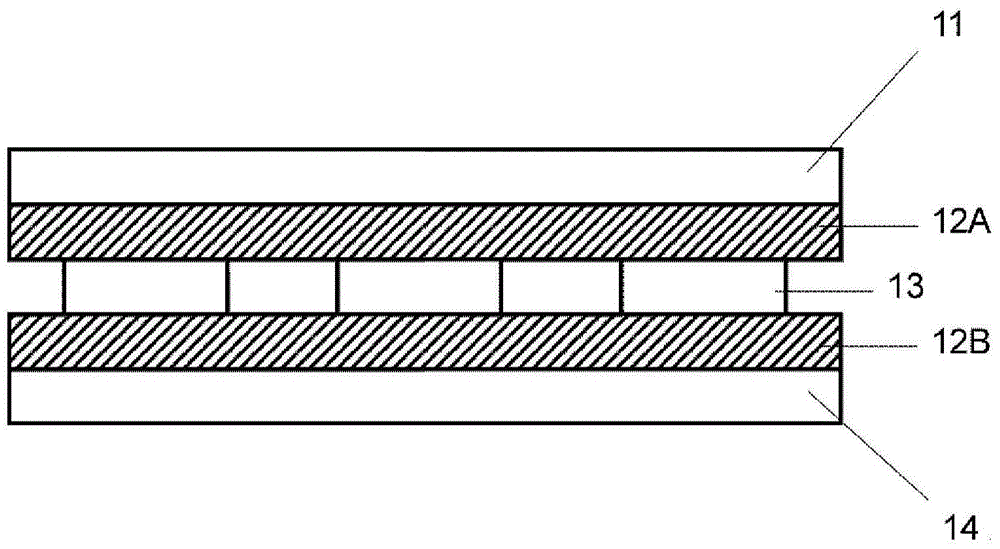

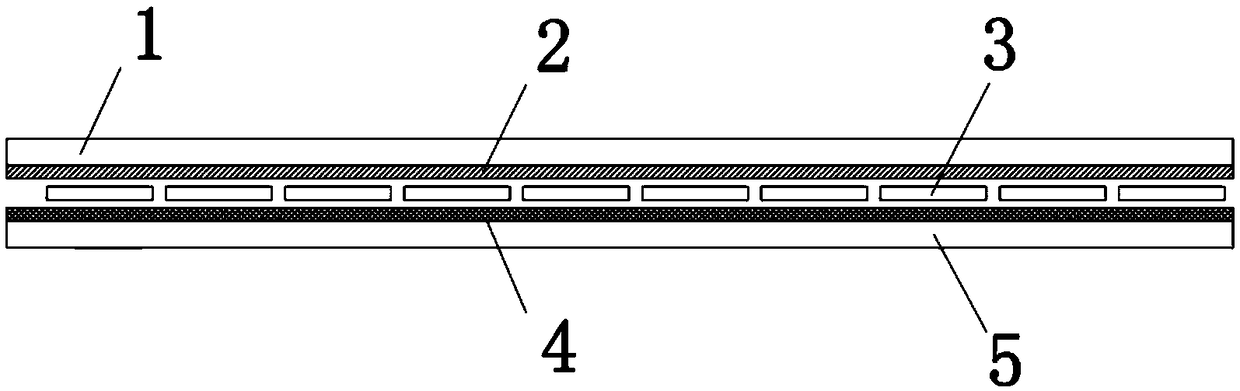

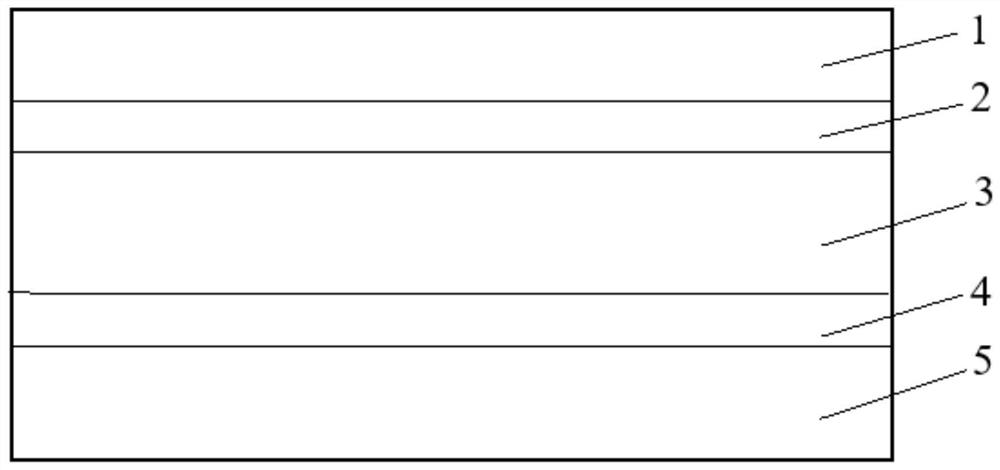

Photovoltaic module containing multilayer packaging adhesive film and preparation method thereof

PendingCN111863996AExcellent anti-PID performanceImprove production yieldNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesiveBattery cell

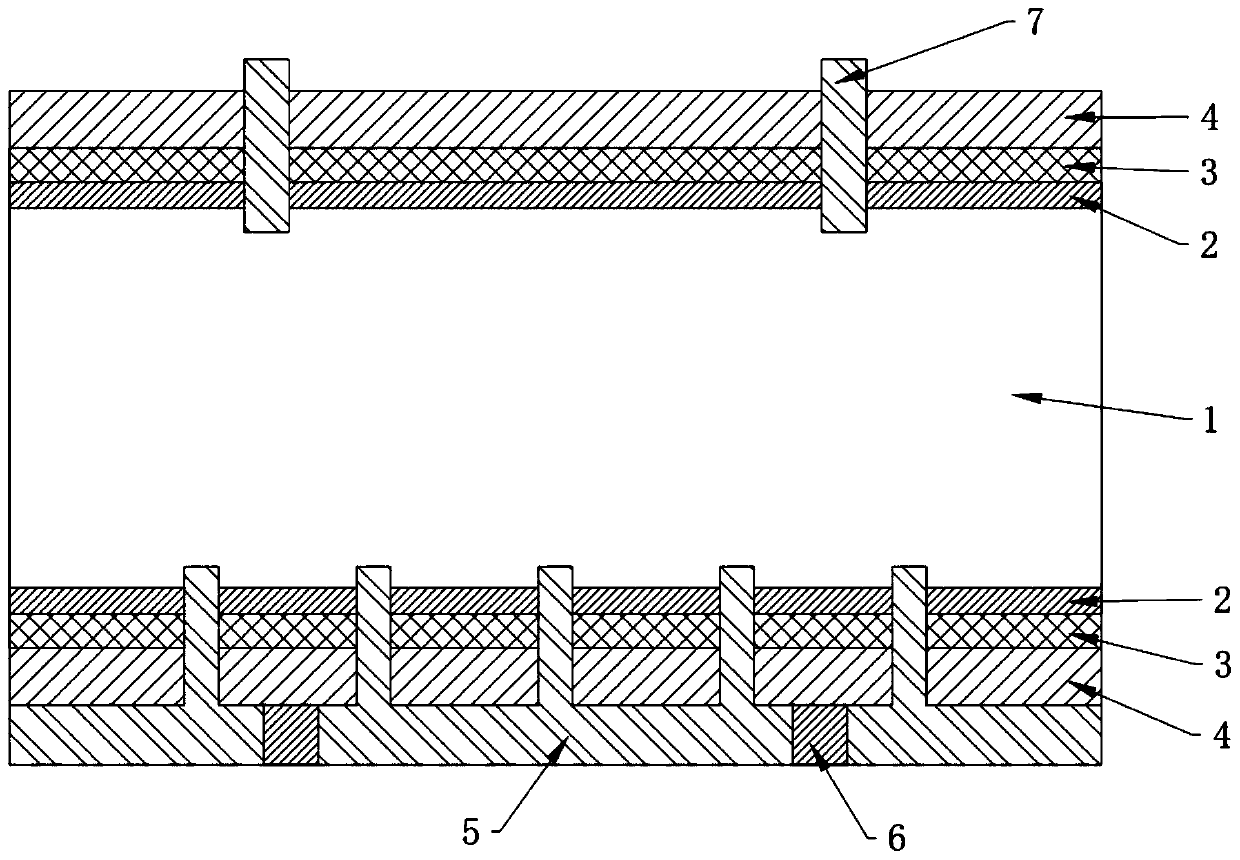

The invention provides a photovoltaic module containing a multilayer packaging adhesive film and a preparation method thereof. The photovoltaic module containing the multilayer packaging adhesive filmcomprises a front plate, an upper layer adhesive film, a battery piece, a lower layer adhesive film and a rear plate which are sequentially arranged from top to bottom, at least one layer of the upper layer adhesive film and the lower layer adhesive film is the multilayer packaging adhesive films, and the multilayer packaging adhesive film comprises at least two layers of packaging adhesive films. The photovoltaic module containing the multilayer packaging adhesive film has excellent PID resistance, and can meet the requirements for the packaging adhesive films with different functions.

Owner:CYBRID TECHNOLOGIES INC

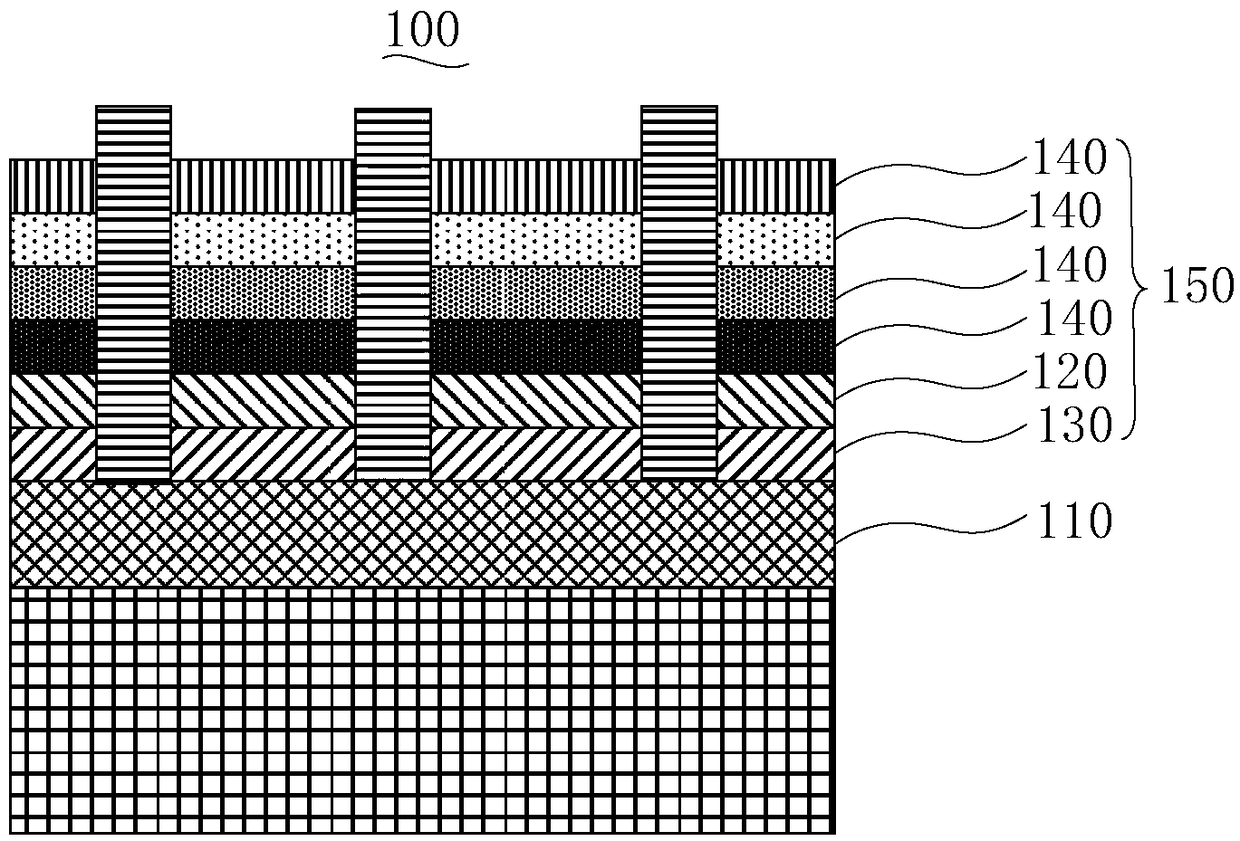

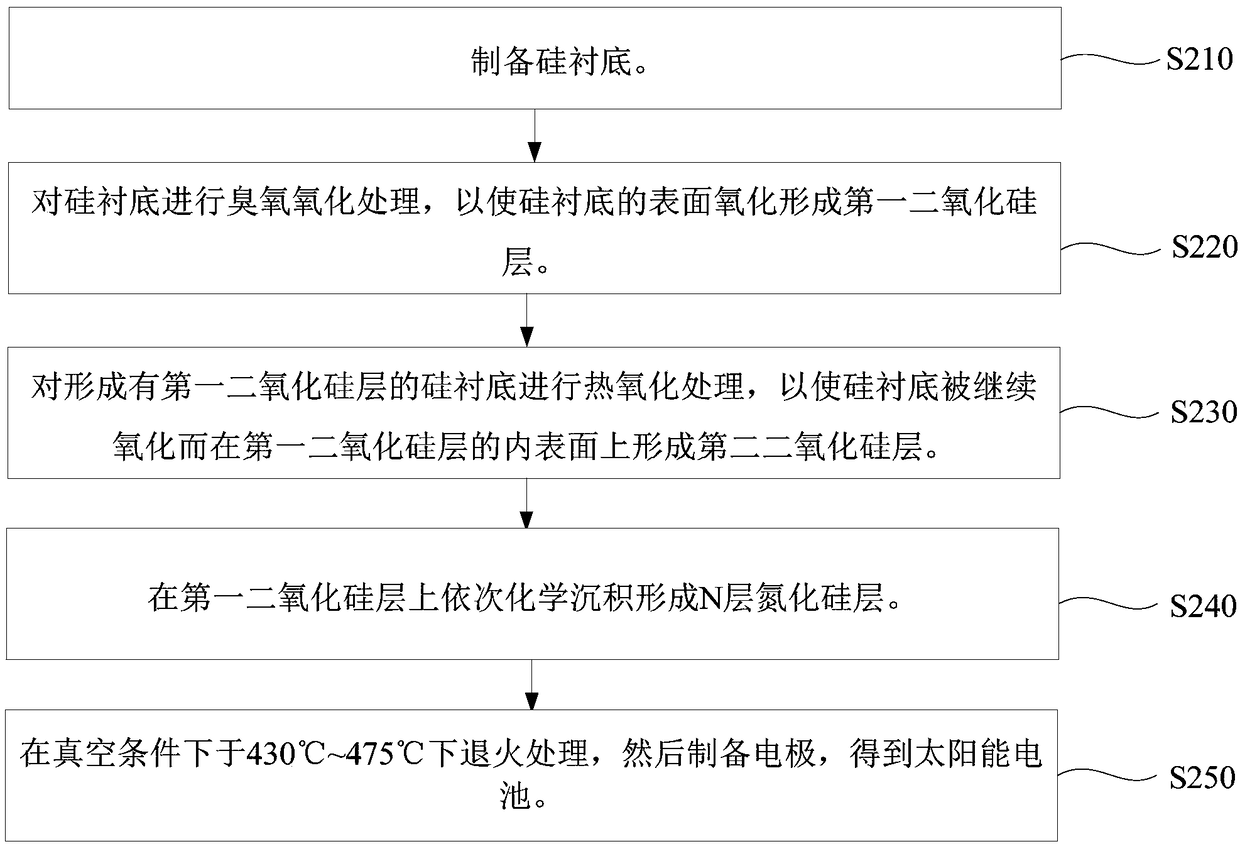

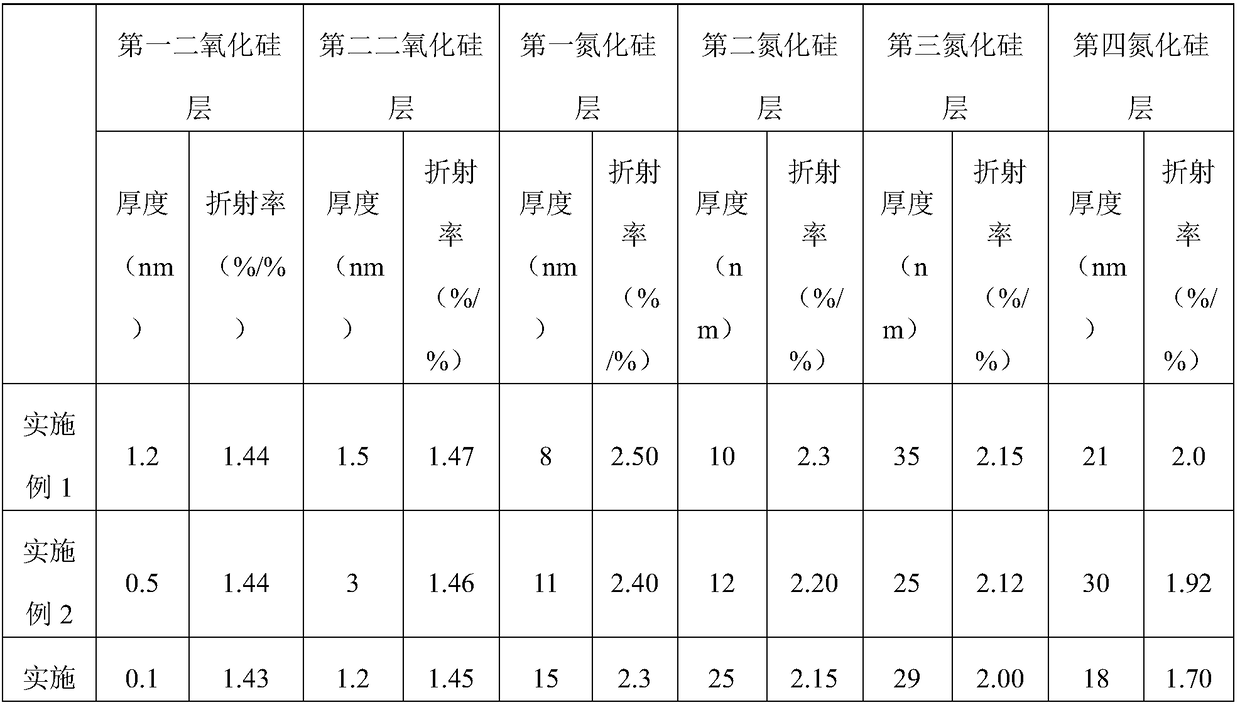

Solar cell and preparation method and photovoltaic module thereof

ActiveCN109004038AGuaranteed anti-PID performanceImprove anti-PID performanceMaterial nanotechnologyFinal product manufactureRefractive indexSolar cell

The invention relates to a solar cell, a preparation method thereof and a photovoltaic module. A second silicon dioxide layer of the solar cell, a first silicon dioxide layer and an N-layer silicon nitride layer are sequentially laminated on a silicon base layer, and the refractive index of the second silicon dioxide layer is larger than the refractive index of the first silicon dioxide layer. From the first silicon dioxide layer to the first silicon dioxide layer, the refractive index of the N-layer silicon nitride layer decreases in turn, and the thickness of the silicon nitride layer closest to the first silicon dioxide layer is the smallest among the N-layer silicon nitride layers. The conversion efficiency of the solar cell is high and the anti-PID performance is good.

Owner:CSG PVTECH +1

Photovoltaic cell module packaging adhesive film, and preparation method and application thereof

ActiveCN113913117AMitigating pitfalls in solar cell applicationsMitigate defectsMacromolecular adhesive additivesFilm/foil adhesives without carriersPolymer sciencePolyolefin

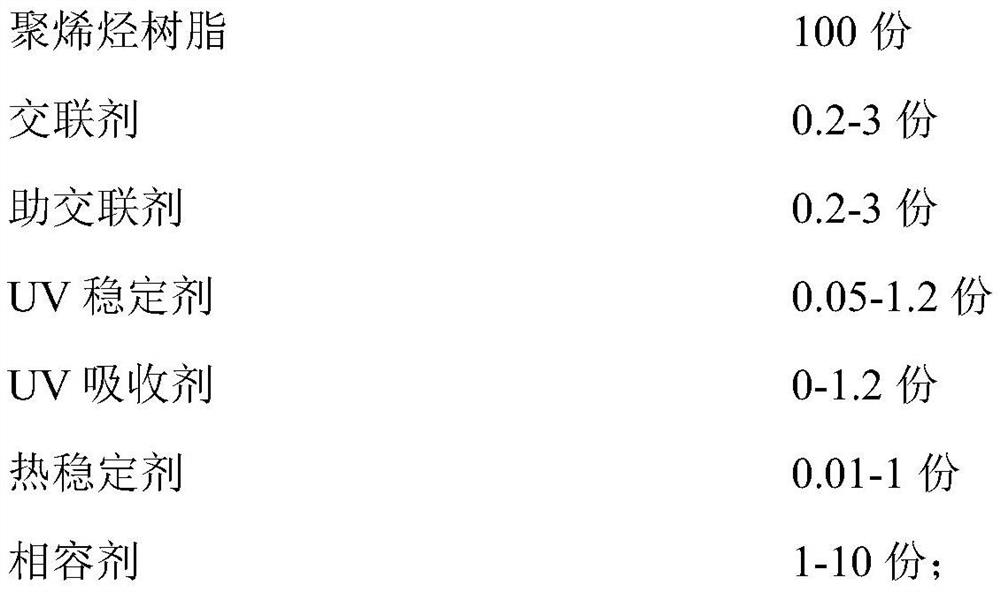

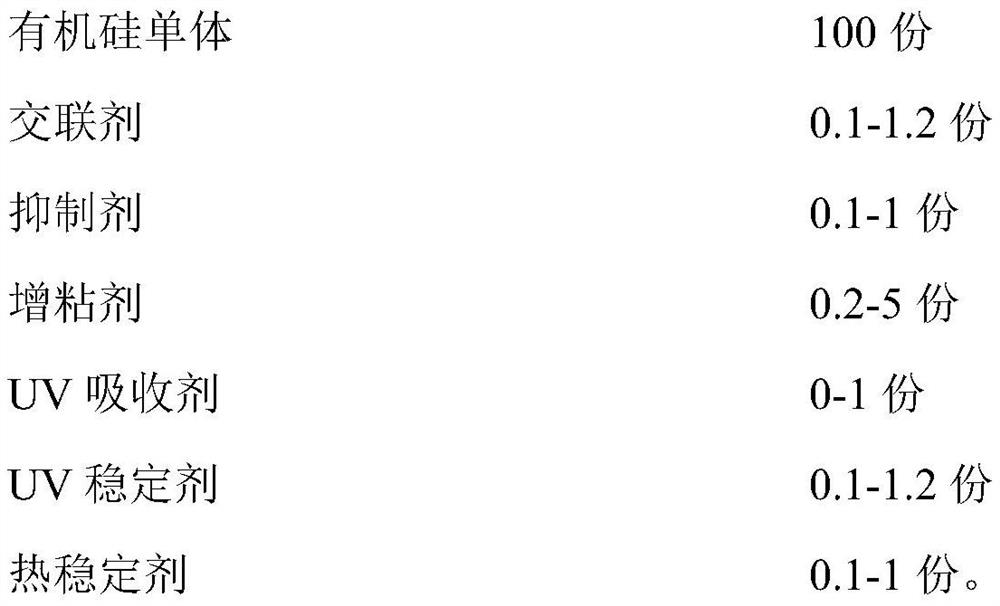

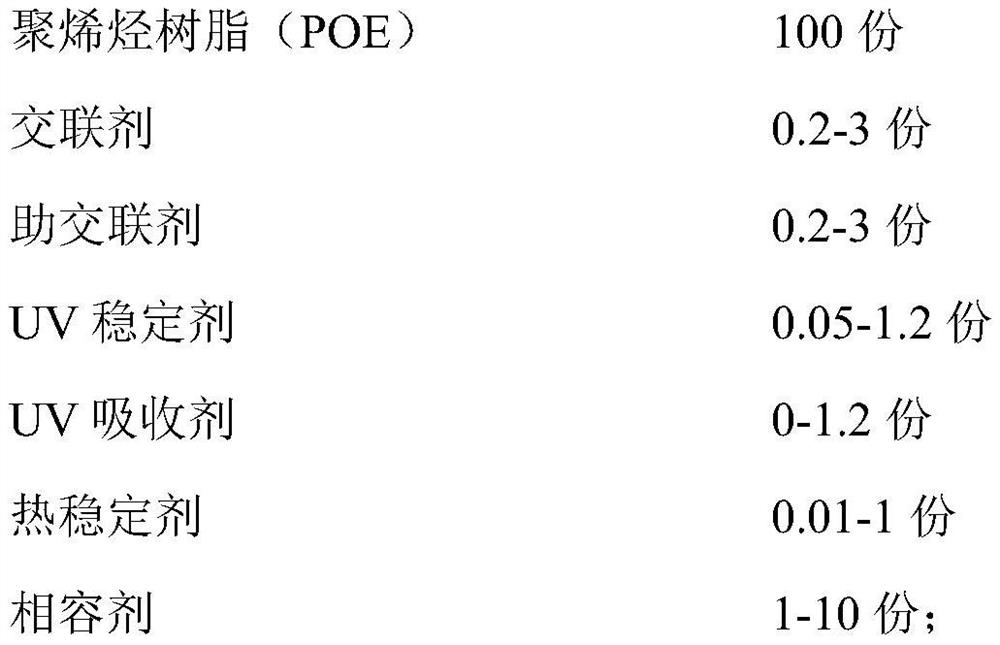

The invention discloses a photovoltaic cell module packaging adhesive film, and a preparation method and application thereof. The photovoltaic cell module packaging adhesive film comprises a polyolefin adhesive film layer, and the polyolefin adhesive film layer comprises polyolefin resin, a cross-linking agent, an assistant cross-linking agent, a UV stabilizer, a UV absorbent, a heat stabilizer and a compatilizer. According to the invention, after the compatibilizer is added into a POE layer, the compatibilizer has polarity, so that the compatibilizer can be well compatible with the auxiliary agent, the auxiliary agent is not easy to separate out and is not easy to slip when being combined with a battery piece, the defects of the POE in the application of the solar battery are relieved, and meanwhile, the compatibilizer still has the advantages of the POE in the application of the solar battery. In addition, due to the addition of the compatilizer, the POE layer and the organic silicon layer can be effectively combined, and the invention further discloses a photovoltaic cell module composite packaging adhesive film comprising a polyolefin adhesive film layer and a silicon rubber film layer located on the surface of the polyolefin adhesive film layer.

Owner:上海润势科技有限公司

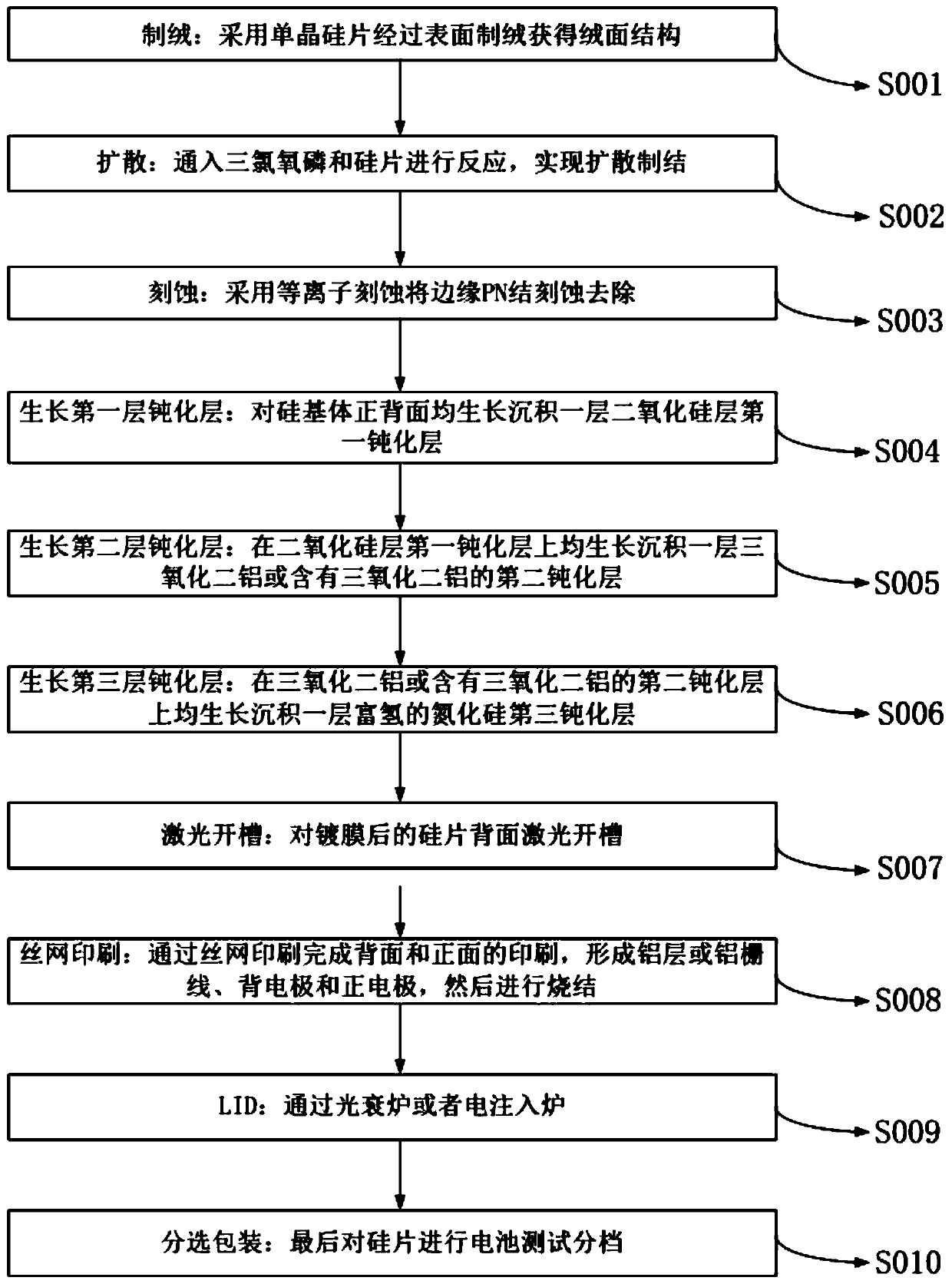

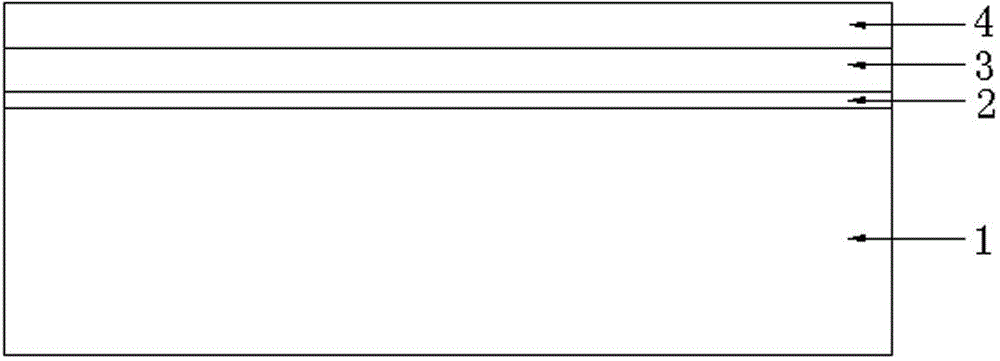

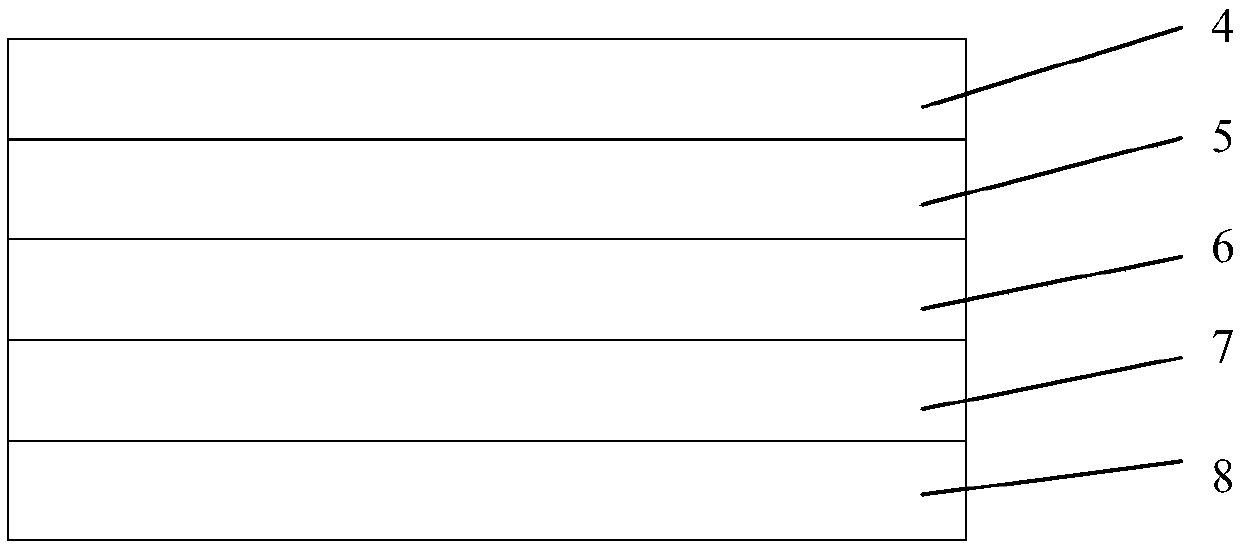

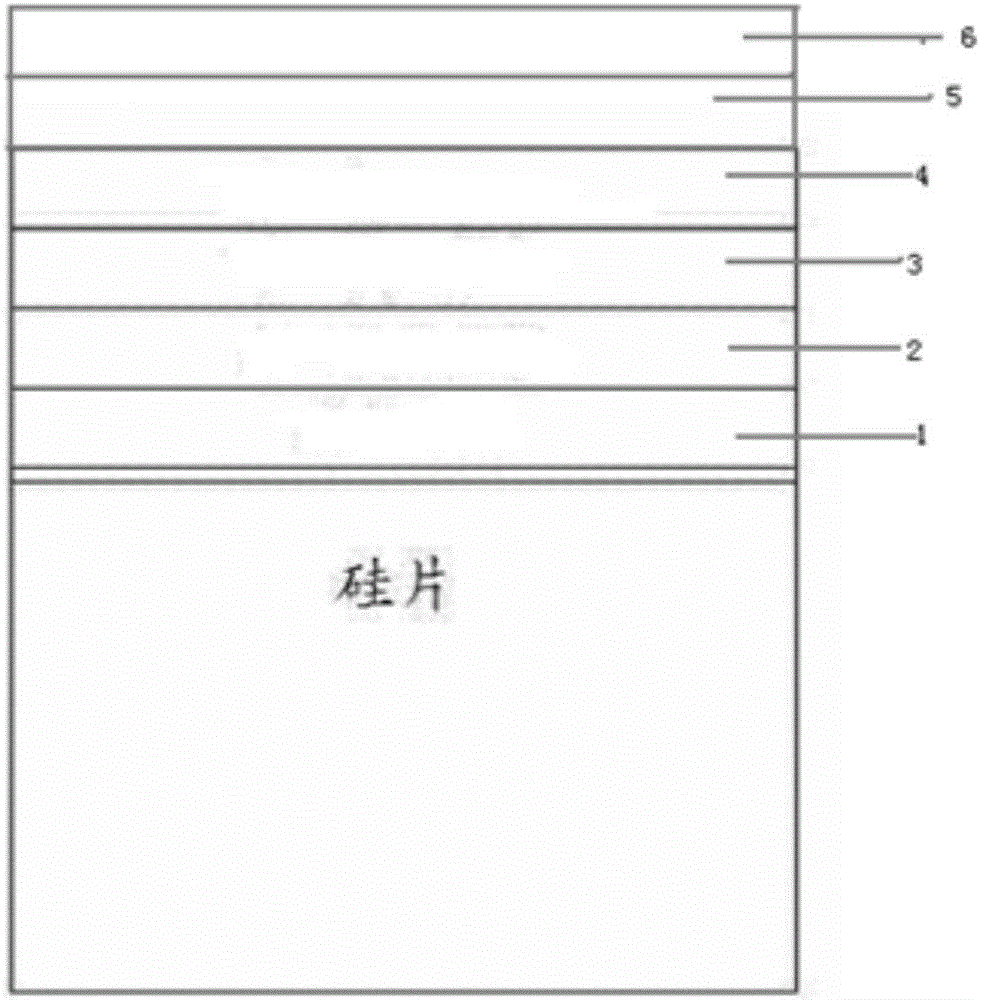

Solar cell with three-passivation layer structure, and preparation method of solar cell

PendingCN109888060AImprove passivation effectImprove anti-PID performanceFinal product manufactureSemiconductor devicesHydrogenSolar cell

The invention discloses a solar cell with a three-passivation layer structure. The solar cell comprises a silicon substrate; a silicon dioxide layer, a first passivation layer, aluminum oxide or a second passivation layer containing the aluminum oxide and a third hydrogen-rich silicon nitride passivation layer are sequentially deposited on each of the front surface and the back surface of the silicon substrate; the third hydrogen-rich silicon nitride passivation layer located on the back surface of the silicon substrate is printed with an aluminum layer or an aluminum gate line and forms ohmiccontact with silicon through laser grooving, and the back surface is provided with a back electrode; and the third hydrogen-rich silicon nitride passivation layer located on the front surface of thesilicon substrate is provided with a positive electrode and an auxiliary gate line. The invention further discloses a preparation method of the solar cell with the three-passivation layer structure. The silicon dioxide film layer is grown and deposited on each of the front surface and the back surface of a silicon wafer, so that the passivation effects of the front and back surfaces are well enhanced, the anti-PID performance of the cell is enhanced, and the cell efficiency can be effectively improved.

Owner:TONGWEI SOLAR HEFEI +4

Preparation method of crystalline silicon solar battery multi-layer antireflection film

InactiveCN104659150AGood anti-PID performanceImprove performanceFinal product manufacturePhotovoltaic energy generationSolar batteryCrystalline silicon

The invention discloses a preparation method of a crystalline silicon solar battery multi-layer antireflection film. When an antireflection film is prepared in a film plating process, firstly, a SiO2 film layer I is prepared on the surface of a solar battery silicon wafer, secondly, a SiO2 film layer II is prepared on the surface of the SiO2 film layer I, and finally, a SiNx antireflection film is prepared on the surface of the SiO2 film layer II. The preparation method comprises the following specific steps: (1), precleaning; (2), preparing the first SiO2 film layer I; (3), preparing the second SiO2 film layer II: plating the second SiO2 film II on the first SiO2 film layer I, inflating oxidizing gas into a PECVD furnace, and performing oxidation reaction to generate the SiO2 film layer II with the thickness of 45-55nm; (4), preparing the SiNxantireflection film. The crystalline silicon solar battery multi-layer antireflection film is high in anti-PID performance and higher in comprehensive performance; the efficiency of the film plating process is improved; the production cost is reduced.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

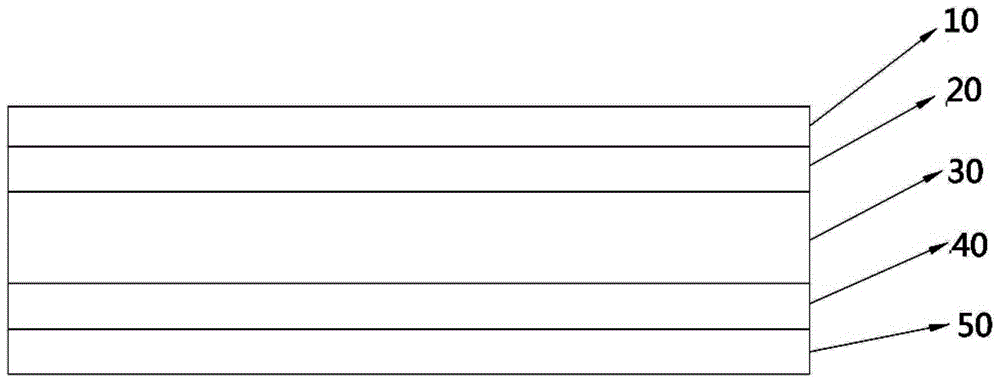

Packaging adhesive film for photovoltaic module

PendingCN110964447AImprove anti-PID performanceImprove bond reliabilityNon-macromolecular adhesive additivesFilm/foil adhesivesPhysical chemistryEngineering

The invention discloses a packaging adhesive film for a photovoltaic module. The packaging adhesive film comprises an outer layer which is in contact with glass or a back plate and has high bonding reliability, an inner layer which has a low stress effect on a battery piece, and a middle layer which has a high PID resistance effect. The overall thickness of the adhesive film is 200-1000 microns; the thickness of the middle layer is in a range of 160-750 microns, and the specific value of the thickness of the middle layer is related to the overall thickness of the film; the inner layer and theouter layer of the adhesive film are both made of EVA resin with a melt flow rate of 2-16 g / min and a VA content of 26%-32%; the middle layer is made of POE resin with a melt flow rate of 5-25 g / min;and the middle layer, the inner layer and the outer layer are all added with an anti-PID aid which is acrylate containing ethyoxyl or propoxyl groups, and the addition amount of the aid in each layerranges from 0.3% to 2.1%.

Owner:SHANGHAI HIUV NEW MATERIALS

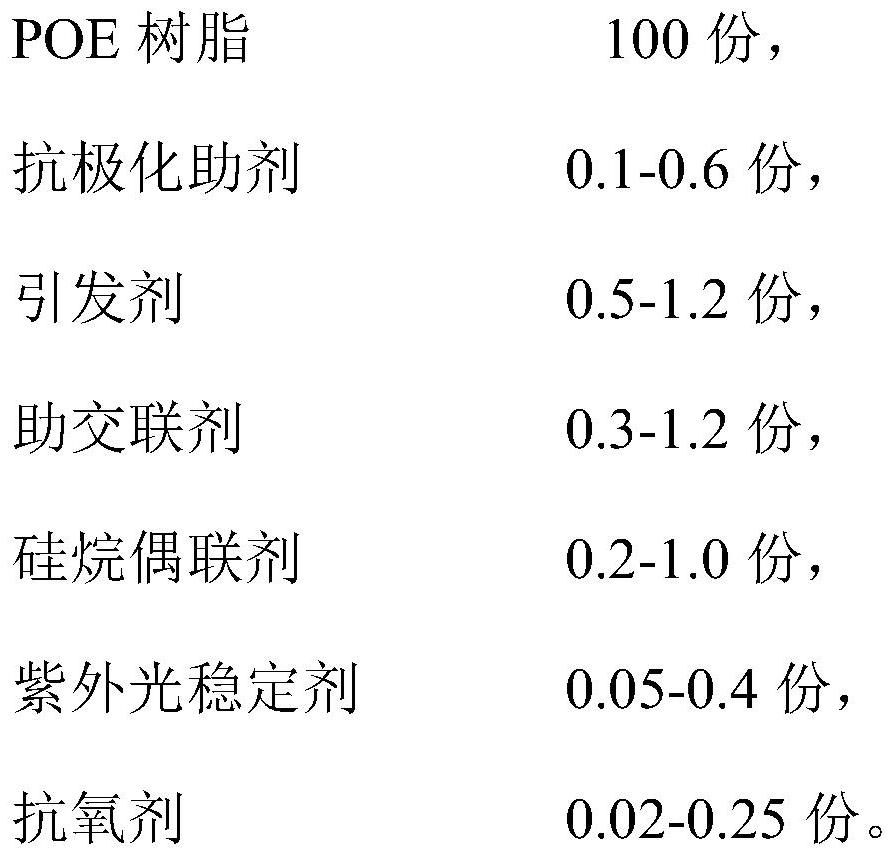

Anti-polarization packaging adhesive film for double-sided battery and preparation method thereof

PendingCN111732902AImprove anti-PID performanceTo avoidNon-macromolecular adhesive additivesFilm/foil adhesives without carriersSemiconductor materialsElectrical battery

The invention relates to the technical field of packaging adhesive films, in particular to a packaging adhesive film capable of improving PID resistance of a double-sided assembly and a preparation method of the packaging adhesive film. The packaging adhesive film comprises the following components in parts by mass: 100 parts of matrix resin, 0.1-20 parts of an N-type semiconductor, 0.01-2 parts of a peroxide cross-linking agent, 0.1-10 parts of an assistant cross-linking agent, 0.01-5 parts of a light stabilizer, 0.05-5 parts of an antioxidant, and 0.1-5 parts of a coupling agent. According to the anti-polarization packaging adhesive film for the double-sided battery, the N-type semiconductor material is added into the adhesive film, so that the adhesive film has certain electrons, polarization positive charges generated by the double-sided battery in the PID process can be neutralized, PID is avoided, and the anti-PID performance of the adhesive film is remarkably improved; the preparation method of the anti-polarization packaging adhesive film for the double-sided battery is simple in preparation process and low in production cost.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Multilayer antireflection coating of crystalline silicon cell and preparation method of multilayer antireflection coating

InactiveCN106449788AImprove anti-PID performanceGood light transmissionFinal product manufacturePhotovoltaic energy generationSilicon nitrideRefractive index

The invention discloses a multilayer antireflection coating of a crystalline silicon cell. The multilayer antireflection coating deposits on an N-shaped side of the crystalline silicon cell and comprises a silicon oxide film, a first silicon nitride film, a second silicon nitride film, a third silicon nitride film, a fourth silicon nitride film and a zirconium dioxide barrier layer from bottom to top, wherein the silicon oxide film is 5-25 nanometers in thickness and 1.4-1.5 in refractive index, the first silicon nitride film is 6-12 nanometers in thickness and 2.25-2.35 in refractive index, the second silicon nitride film is 18-25 nanometers in thickness and 2.15-2.24 in refractive index, the third silicon nitride film is 35-55 nanometers in thickness and 2.05-2.14 in refractive index, the fourth silicon nitride film is 15-30 nanometers in thickness and 1.95-2.04 in refractive index, and the zirconium dioxide barrier layer is 30-50 nanometers in thickness. The multilayer antireflection coating of the crystalline silicon cell has the advantages of fast short wave response, low refractive index, excellent light permeability and the like.

Owner:庞倩桃

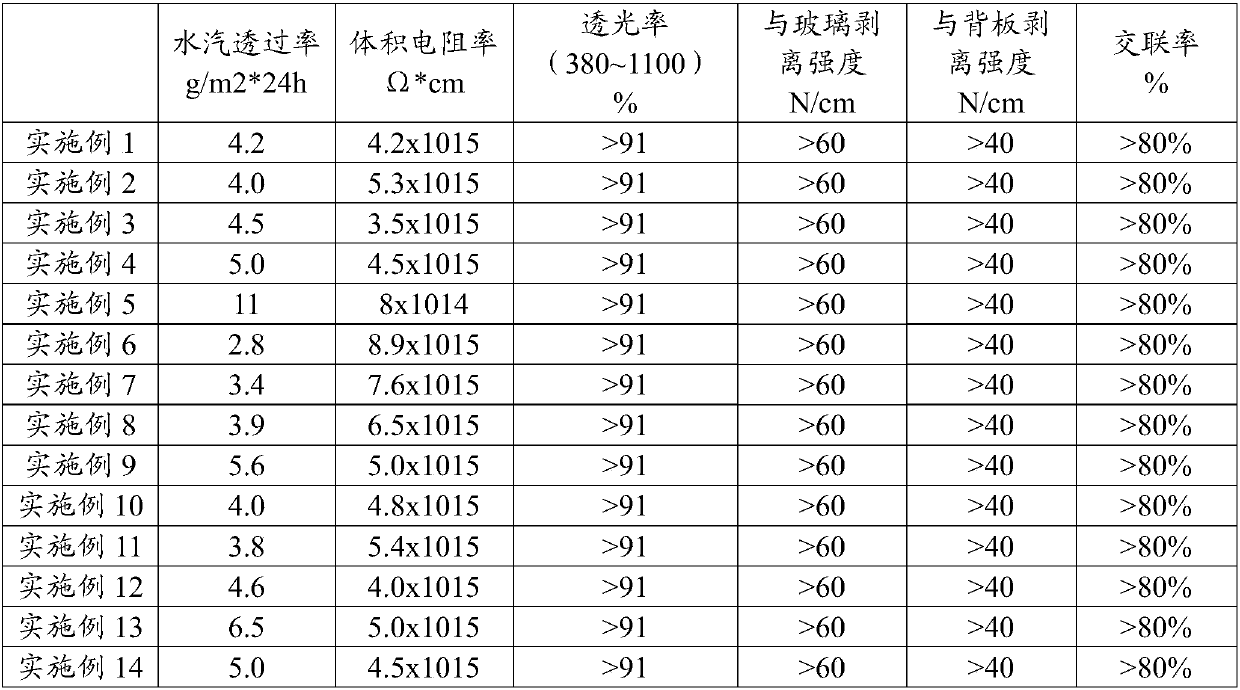

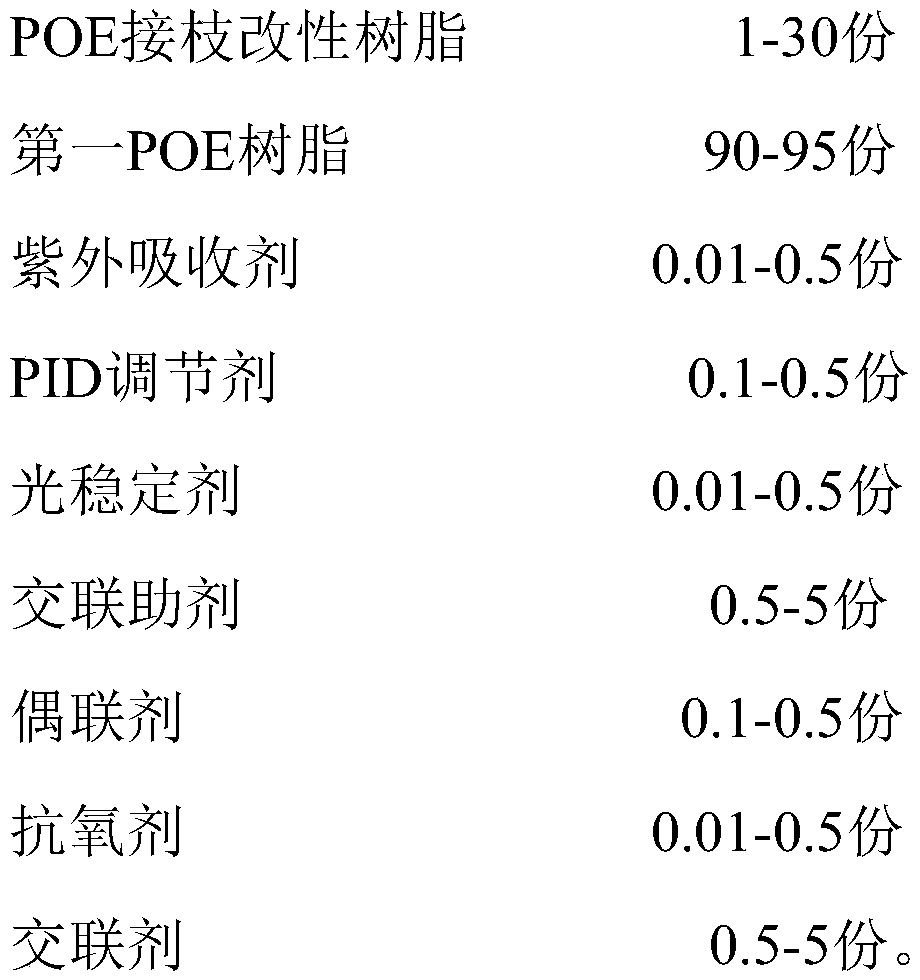

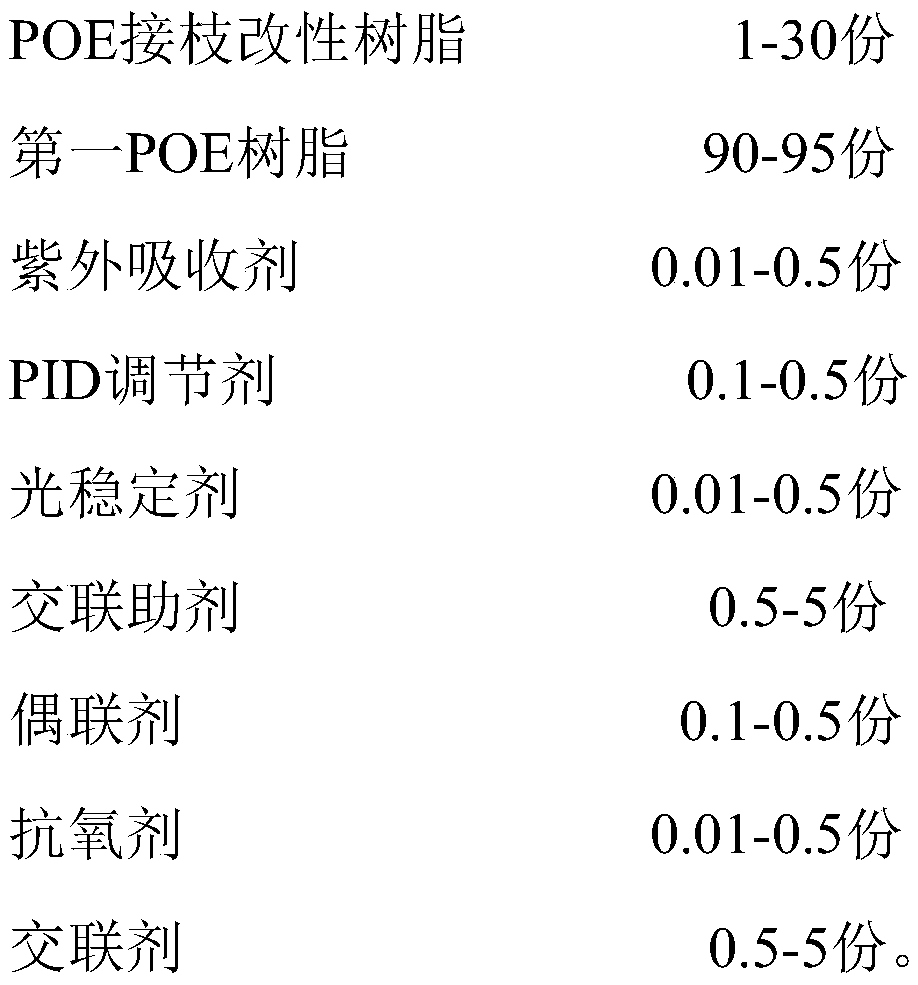

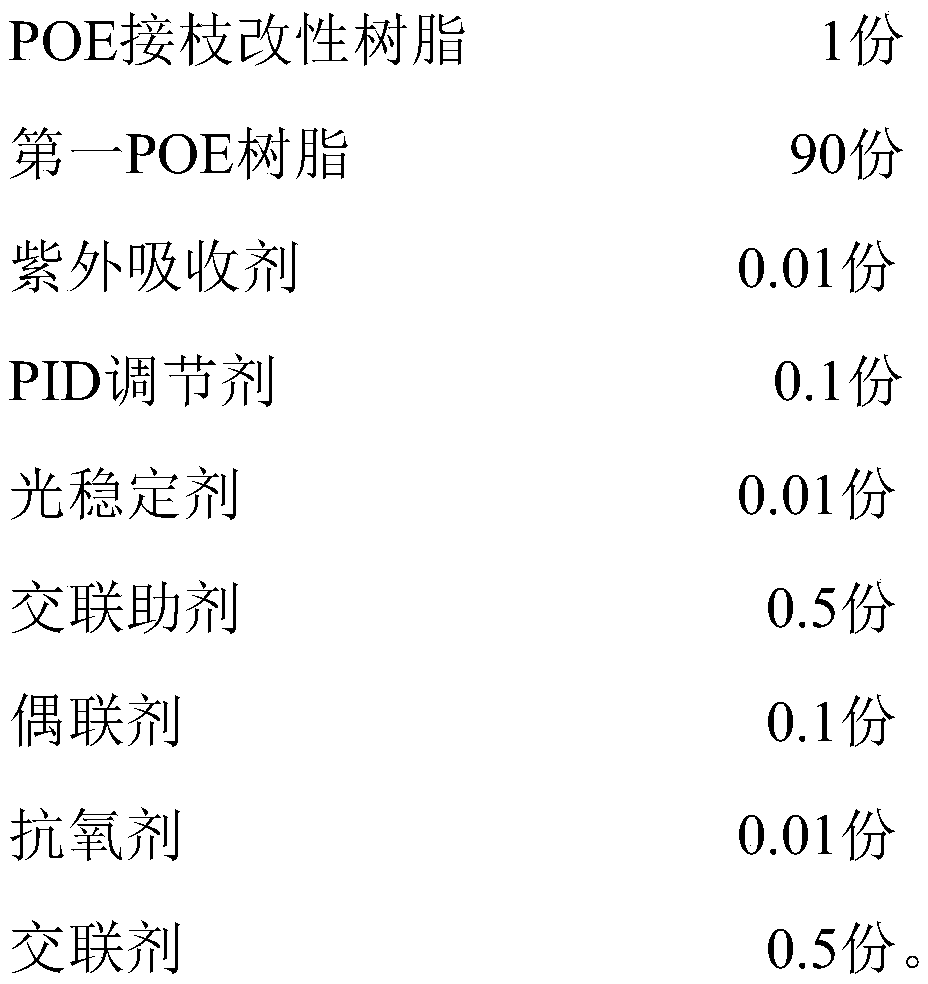

Anti-PID POE adhesive film special for photovoltaic double-glass assembly packaging and preparation method thereof

ActiveCN111518487AReduce electricity costsGuaranteed reliabilityNon-macromolecular adhesive additivesFilm/foil adhesives without carriersUv absorbancePhysical chemistry

The invention relates to the technical field of solar cell packaging adhesive film, in particular to an anti-PID POE adhesive film special for photovoltaic double-glass assembly packaging and a preparation method thereof. The anti-PID POE adhesive film is prepared from the following raw materials in parts by weight: 1 to 30 parts of POE graft modified resin; 90 to 95 parts of first POE resin, 0.01to 0.5 part of an ultraviolet absorbent, 0.1 to 0.5 part of a PID regulator, 0.01 to 0.5 part of a light stabilizer, 0.5 to 5 parts of a cross-linking auxiliary agent, 0.1 to 0.5 part of a coupling agent, 0.01 to 0.5 part of an antioxidant and 0.5 to 5 parts of a cross-linking agent. Compared with an adhesive film used in the current industry, the POE adhesive film provided by the invention has better PID resistance and aging resistance, and can ensure that the power attenuation of PID is controlled within 3.0% after 192 hours.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

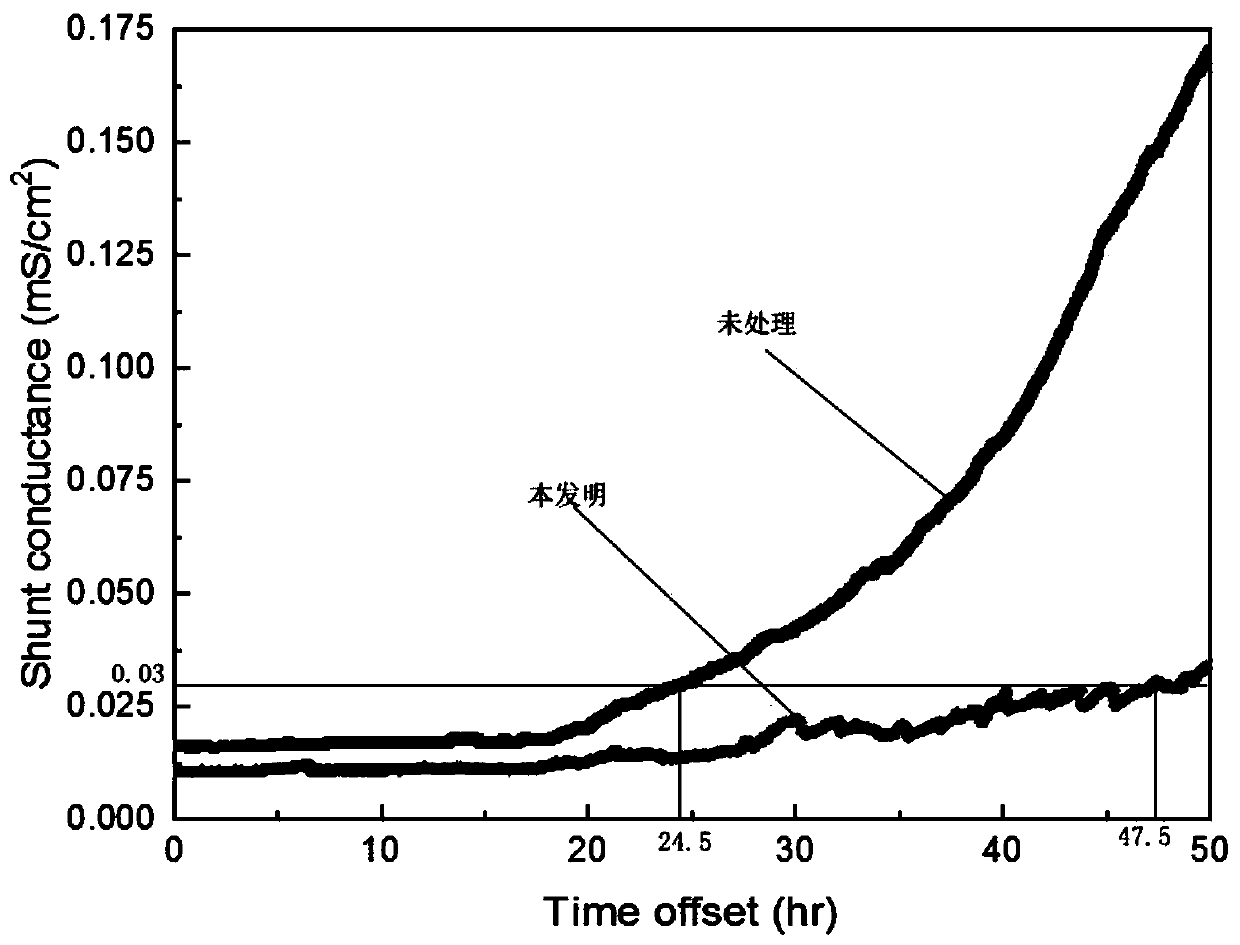

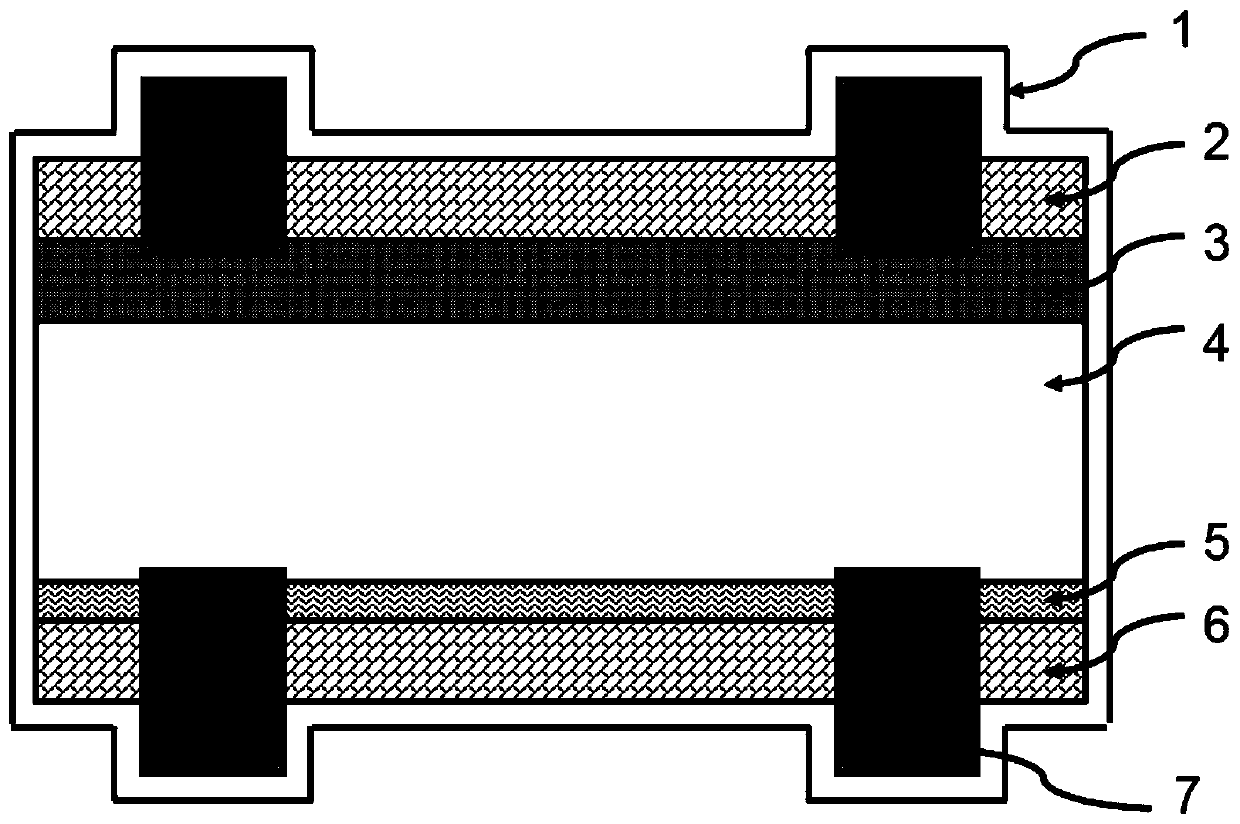

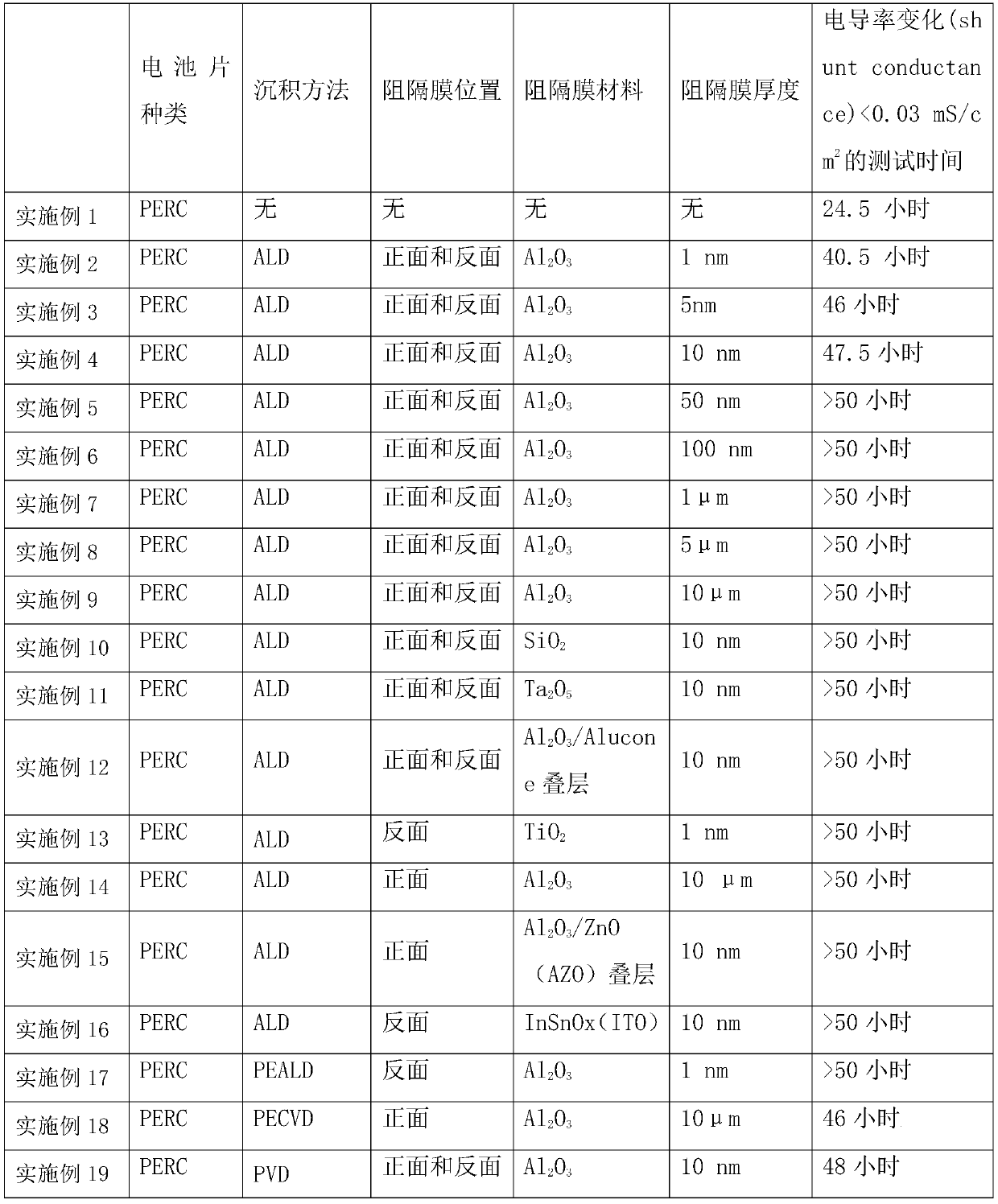

Crystalline silicon solar cell and preparation method thereof

InactiveCN110061073ASolve or improve anti-PID performanceImprove anti-PID performanceFinal product manufacturePhotovoltaic energy generationSilicon solar cellDiffusion barrier

The invention relates to the field of photovoltaic cells, to be specific, relates to a crystalline silicon solar cell and a preparation method thereof. The invention is characterized in that a surfaceof a cell piece is provided with a barrier film; the surface of the finished cell piece is further provided with the barrier film in a coated manner to form an ion diffusion barrier layer, and one surface or two surfaces of the finished battery piece are wrapped to be used as a diffusion barrier layer for blocking external ions from migrating to the battery, and therefore, the PID resistance of the cell is improved, the passivation and anti-reaction effects are improved at the same time, and the photoelectric conversion efficiency of the battery is improved; the coating film on the surface ofthe cell piece can also be used for protecting the electrode from oxidation and resisting aging. ALD or PEALD technology is preferably used, and the dense pinhole-free performance of the ALD thin film is fully used to further improve the PID resistance of the cell.

Owner:JIANGSU MICROVIA NANO EQUIP TECH CO LTD

Multilayer coextruded anti-polarization composite adhesive film and preparation method thereof

InactiveCN110041835AGood compatibilitySolve the bubblesNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveVapor barrierOptical transmittance

The invention relates to the technical field of photovoltaic module packaging adhesive films, in particular to a multilayer coextruded anti-polarization composite adhesive film. The composite adhesivefilm comprises a POE layer, an anti-polarization layer and an EVA layer arranged from top to bottom sequentially. After adoption of the structure, the composite adhesive film has the benefits as follows: 1, the EVA layer making contact with a battery surface has better compatibility with a polarity aid, and bubble, non-melting and piece combining problems during module lamination can be solved; 2, ethylene segments contained in copolymer resin in the anti-polarization layer have better compatibility with POE and EVA, and higher surface bonding can be formed; besides, acrylate has higher polarization performance, and negative voltage values produced by modules through outer frames can be reduced, so that the anti-PID performance of modules is improved; 3, the POE layer making contact witha back plate and glass has better vapor barrier performance, the light transmittance and volume resistivity of the adhesive film can be increased, thus, electric potential on battery pieces can be increased, the power generation efficiency of the modules can be improved, and the service life of the modules can be prolonged.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com