Water-based environment-friendly white glaze for high-reflection anti-PID photovoltaic backboard glass and preparation method of water-based environment-friendly white glaze

A photovoltaic backplane, high-reflection technology, applied in the coating and other directions, can solve the problems of yellowing, low reflectivity and blackening of the glaze layer, to ensure adhesion, high reflectivity and anti-PID performance, improve anti-PID performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

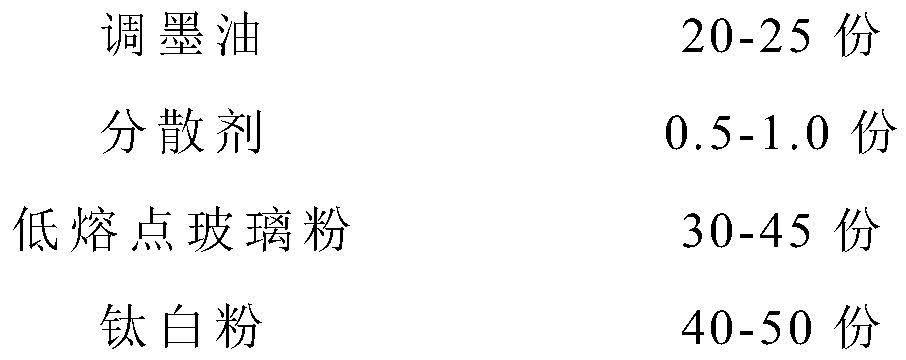

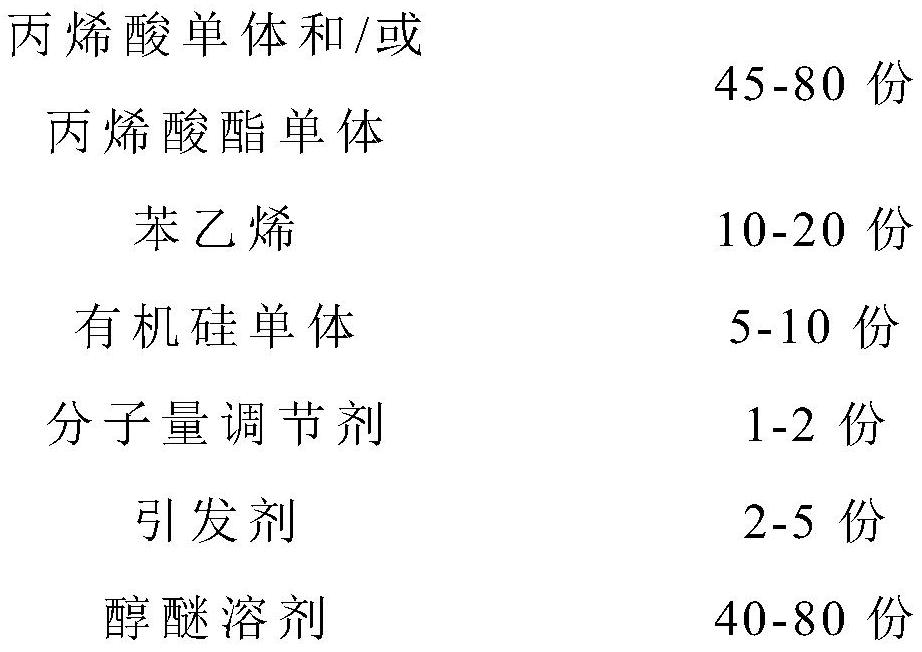

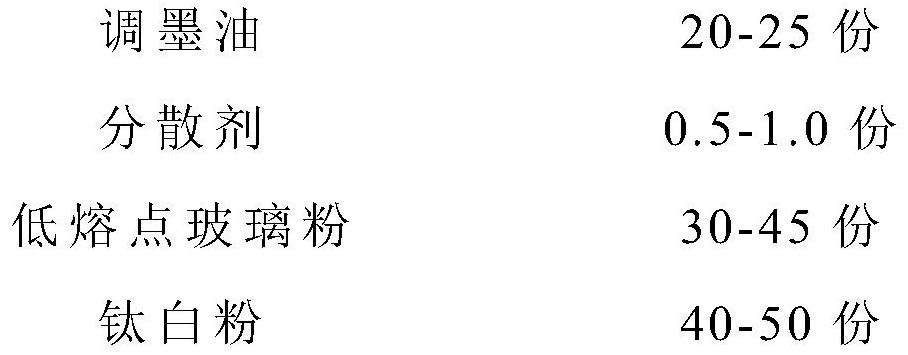

Method used

Image

Examples

Embodiment 1

[0041] The preparation of the water-based environmentally friendly white glaze for the high-reflection anti-PID photovoltaic backplane glass in this embodiment includes the following steps:

[0042] (1) Polymerization preparation of silicone modified water-soluble acrylic resin:

[0043] (a) Keep the reactor clean and dry, add 40 parts by weight of alcohol ether solvent, feed nitrogen into the reactor and maintain it, feed cooling water into the condenser, and heat the alcohol ether solvent to 140°C.

[0044] (b) Take another dispersing kettle, add 10 parts of glycidyl tertiary carbonate, 5 parts of hydroxyethyl acrylate, 3 parts of methyl methacrylate, 5 parts of acrylic acid, 10 parts of isobornyl methacrylate in parts by weight , 25 parts of butyl acrylate, 15 parts of styrene, 5 parts of organosilicon monomer, 2 parts of molecular weight regulator (chain transfer agent), 3.5 parts of initiator; stir and mix evenly, the stirring speed is 300r / min, and the stirring time is 4...

Embodiment 2

[0055] The preparation of the water-based environmentally friendly white glaze for the high-reflection anti-PID photovoltaic backplane glass in this embodiment includes the following steps:

[0056] (1) Polymerization preparation of silicone modified water-soluble acrylic resin:

[0057] (a) Keep the reactor clean and dry, add 40 parts by weight of alcohol ether solvent, feed nitrogen into the reactor and keep it, feed cooling water into the condenser, and heat the alcohol ether solvent to 150°C.

[0058] (b) Take another dispersion kettle, add 15 parts of glycidyl tertiary carbonate, 5 parts of hydroxyethyl acrylate, 5 parts of methyl methacrylate, 5 parts of acrylic acid, 5 parts of isobornyl methacrylate in parts by weight , 35 parts of butyl acrylate, 15 parts of styrene, 5 parts of organosilicon monomer, 1.5 parts of molecular weight modifier (chain transfer agent), 4 parts of initiator; stir and mix evenly, the stirring speed is 300r / min, and the stirring time is 30min ...

Embodiment 3

[0069] The preparation of the water-based environmentally friendly white glaze for the high-reflection anti-PID photovoltaic backplane glass in this embodiment includes the following steps:

[0070] (1) Polymerization preparation of silicone modified water-soluble acrylic resin:

[0071] (a) Keep the reactor clean and water-free, add 40 parts by weight of alcohol ether solvent, feed nitrogen into the reactor and maintain, feed cooling water into the condenser, and heat the alcohol ether solvent to 145°C.

[0072] (b) Take another dispersing kettle, add 12 parts of glycidyl tertiary carbonate, 10 parts of hydroxyethyl acrylate, 5 parts of methyl methacrylate, 3 parts of acrylic acid, 10 parts of isobornyl methacrylate in parts by weight , 30 parts of butyl acrylate, 10 parts of styrene, 8 parts of organosilicon monomer, 2 parts of molecular weight regulator (chain transfer agent), 5 parts of initiator; stir and mix evenly, the stirring speed is 300r / min, and the stirring time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com