Multi-layer packaging material used for solar module and preparation technology and device thereof

A technology of solar modules and packaging materials, applied in applications, electronic equipment, household appliances, etc., can solve the problems of low production efficiency, large investment, and many processes, and achieve the goal of improving production efficiency, reducing production costs, and improving physical and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Various exemplary embodiments, features and aspects of the present invention will be described in detail below with reference to the embodiments. In order to better illustrate the present invention, numerous specific details are given in the following specific embodiments. It will be understood by those skilled in the art that the present invention may be practiced without these specific details. In some other examples, well-known methods, means, and materials are not described in detail, so as to highlight the gist of the present invention.

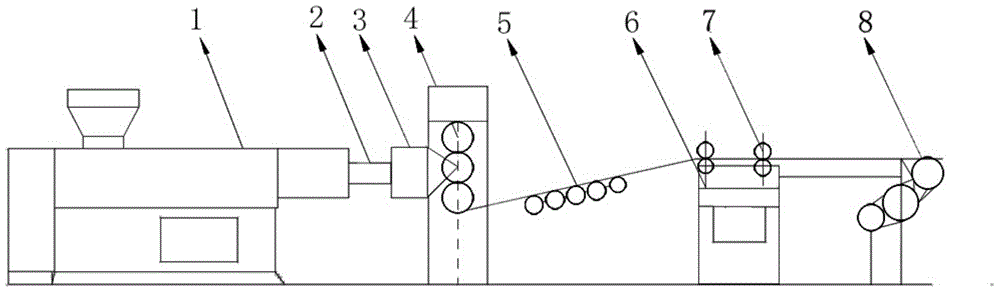

[0031] figure 1 It is a schematic diagram of process equipment flow structure. The screw extruder 1, connecting head 2, co-extrusion molding head 3, three-roll calender unit 4, cooling chill roll 5, tractor 6, shearing machine 7, and finished product curling device 8 are connected in sequence. There may be one screw extruder 1 or three.

[0032] The POE surface layer A is prepared from the following raw materials calculated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com