EVA adhesive film for encapsulating solar cell and preparing process of EVA adhesive film

A technology of solar cells and adhesive films, applied in circuits, adhesives, photovoltaic power generation, etc., can solve problems such as accelerating PID, and achieve the effect of improving anti-PID performance and excellent water vapor barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

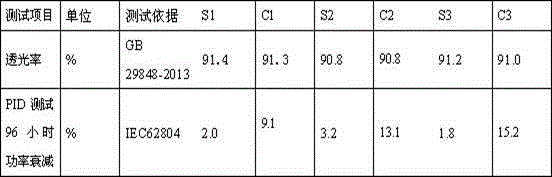

Examples

Embodiment 1

[0029] An EVA adhesive film for solar cell encapsulation, its raw materials are: photovoltaic grade EVA particles (among them, VA content 25%, melt index 20g / 10min / 190℃) 100kg, crosslinking agent 2,5-dimethyl-2 , 5-di(tert-butyl peroxide) hexane 0.5kg, cross-linking aid triallyl isocyanurate 1kg, antioxidant β-(3,5-di-tert-butyl-4-hydroxy 0.05kg of n-octadecanyl phenyl) propionate, 0.01kg of ultraviolet light absorber 2-hydroxy-4-n-octyloxybenzophenone, light stabilizer sebacic acid bis-2,2,6,6 - 0.2 kg of tetramethylpiperidinol ester, 0.1 kg of vinyltrimethoxysilane as tackifier, and 0.05 kg of nano-sized polyacrylamide powder.

[0030] The preparation process of the above-mentioned EVA adhesive film for solar cell encapsulation, the steps are: firstly add the above-mentioned raw materials into the mixer and mix them uniformly; Winding and other steps to obtain the EVA film for solar cell encapsulation.

[0031] The product obtained in Example 1 is marked as S1.

Embodiment 2

[0033] An EVA adhesive film for solar cell encapsulation, its raw materials are: photovoltaic grade EVA particles (among them, VA content 26%, melt index 23g / 10min / 190℃) 100kg, crosslinking agent peroxide-2-ethylhexyl carbonate tert-butyl ester 1kg, crosslinking agent trimethylolpropane trimethacrylate 0.3kg, antioxidant tris(nonylphenyl) phosphite 0.5kg, ultraviolet light absorber 2-(3,5- Di-tert-amyl-2-hydroxyphenyl) benzotriazole 0.3kg, light stabilizer bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate 0.01kg, 0.3 kg of tackifier vinyl triethoxysilane, 0.1 kg of nano-sized polyacrylamide powder.

[0034] The preparation process of the above-mentioned EVA adhesive film for solar cell encapsulation, the steps are: firstly add the above-mentioned raw materials into the mixer and mix them uniformly; Winding and other steps to obtain the EVA film for solar cell encapsulation.

[0035] The product obtained in Example 2 is marked as S2.

Embodiment 3

[0037] An EVA adhesive film for solar cell encapsulation, its raw materials are: photovoltaic grade EVA particles (among them, VA content 28%, melting index 25g / 10min / 190℃) 100kg, crosslinking agent peroxide-2-ethylhexyl carbonate 1.5 kg of tert-butyl ester, 1.5 kg of triallyl cyanurate, 0.3 kg of antioxidant tris(nonylphenyl) phosphite, 2-(2'-hydroxyl-5 '-tert-octylphenyl) benzotriazole 0.2kg, polymer of succinic acid and 4-hydroxy-2,2,6,6-tetramethyl-1-piperidinol 0.1kg, tackifier 3 - 0.5 kg of glycidyl etheroxypropyl trimethoxysilane, 0.5 kg of nano-sized polyacrylamide particles.

[0038] The preparation process of the above-mentioned EVA adhesive film for solar cell encapsulation, the steps are: firstly add the above-mentioned raw materials into the mixer and mix them uniformly; Winding and other steps to obtain the EVA film for solar cell encapsulation.

[0039] The product obtained in Example 3 is marked as S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com