Preparation method of ultraviolet-resistant and damp-heat aging-resistant copolyester

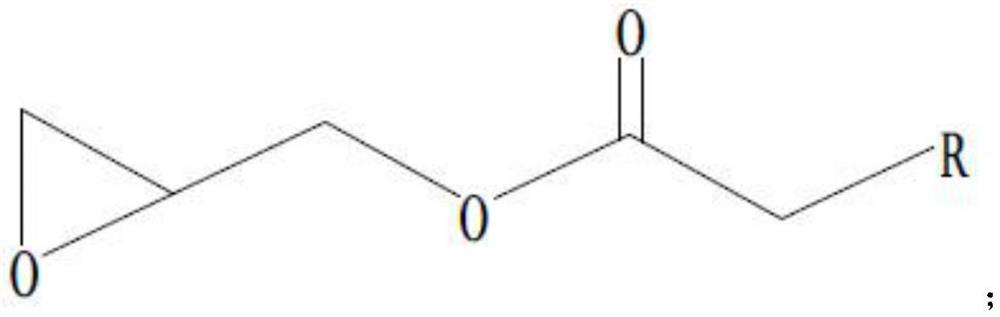

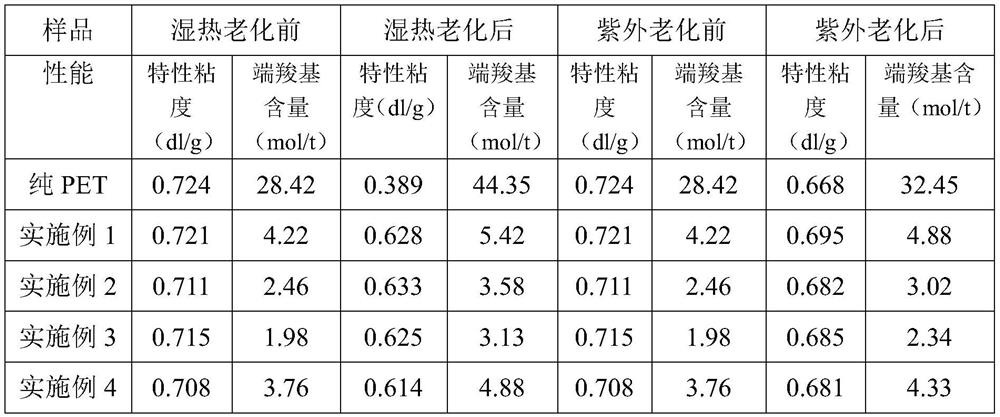

A technology of copolyester and heat and humidity resistance, which is applied in the field of polyester preparation, can solve problems such as complex preparation process, achieve the effect of reducing the content of terminal carboxyl groups, reducing the content of ester bonds, and improving the water vapor barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 1600g of terephthalic acid, 400g of 2,6-naphthalene dicarboxylic acid, 1200g of ethylene glycol, 0.6g of catalyst, and 1.05g of stabilizer into a 5L reaction kettle, replace the air in the polymerization kettle with inert gas, and then stir for 10min to dissolve the materials Mix evenly, control the pressure in the polymerization tank at 0.1-0.4MPa, the speed of the agitator at 50-120r / min, control the temperature in the polymerization tank at 220-250°C, calculate the esterification efficiency by the liquid output rate, when the conversion rate reaches 90- At 100%, the esterification reaction ends and the pressure is released.

[0027] Vacuumize the reactor, control the pressure of the reactor at 0.5-1kPa, control the temperature in the polymerization tank at 240-270°C, and react for 20-50 minutes; then control the pressure of the reactor at 50-300Pa, and control the temperature in the polymerization tank at 270-290°C. Reaction 90~180min.

[0028] Add 40 g of a mon...

Embodiment 2

[0030] Add 1500g of terephthalic acid, 500g of dimethyl 2,6-naphthalene dicarboxylate, 1000g of ethylene glycol, 1.5g of antimony acetate, and 0.75g of stabilizer into a 5L reaction kettle, replace the air in the polymerization kettle with an inert gas, and then Stir for 15 minutes to mix the materials evenly, control the pressure in the polymerization tank at 0.1-0.4 MPa, the speed of the agitator at 50-120r / min, control the temperature in the polymerization tank at 220-250°C, calculate the esterification efficiency by the liquid output rate, when the conversion When the rate reaches 90-100%, the esterification reaction ends and the pressure is released.

[0031] Vacuumize the reactor, control the pressure of the reactor at 0.5-1kPa, control the temperature in the polymerization tank at 240-270°C, and react for 20-50 minutes; then control the pressure of the reactor at 50-300Pa, and control the temperature in the polymerization tank at 270-290°C. Reaction 90~180min.

[0032]...

Embodiment 3

[0034] Add 1000g of terephthalic acid, 200g of isophthalic acid, 800g of 2,6-naphthalene dicarboxylic acid, 1500g of propylene glycol, 1.0g of catalyst, and 10.0g of stabilizer into a 5L reaction kettle, replace the air in the polymerization kettle with inert gas, and then Stir for 15 minutes to mix the materials evenly, control the pressure in the polymerization tank at 0.1-0.4 MPa, the speed of the agitator at 50-120r / min, control the temperature in the polymerization tank at 220-250°C, calculate the esterification efficiency by the liquid output rate, when the conversion When the rate reaches 90-100%, the esterification reaction ends and the pressure is released.

[0035] Vacuumize the reactor, control the pressure of the reactor at 0.5-1kPa, control the temperature in the polymerization tank at 240-270°C, and react for 20-50 minutes; then control the pressure of the reactor at 50-300Pa, and control the temperature in the polymerization tank at 270-290°C. Reaction 90~180min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com