Barrier type CIGS solar cell and preparation method thereof

A technology of solar cells and surface electrodes, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of CIGS failure and poor water vapor barrier performance, and achieve the effects of improving work stability, prolonging service life, and improving water vapor barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

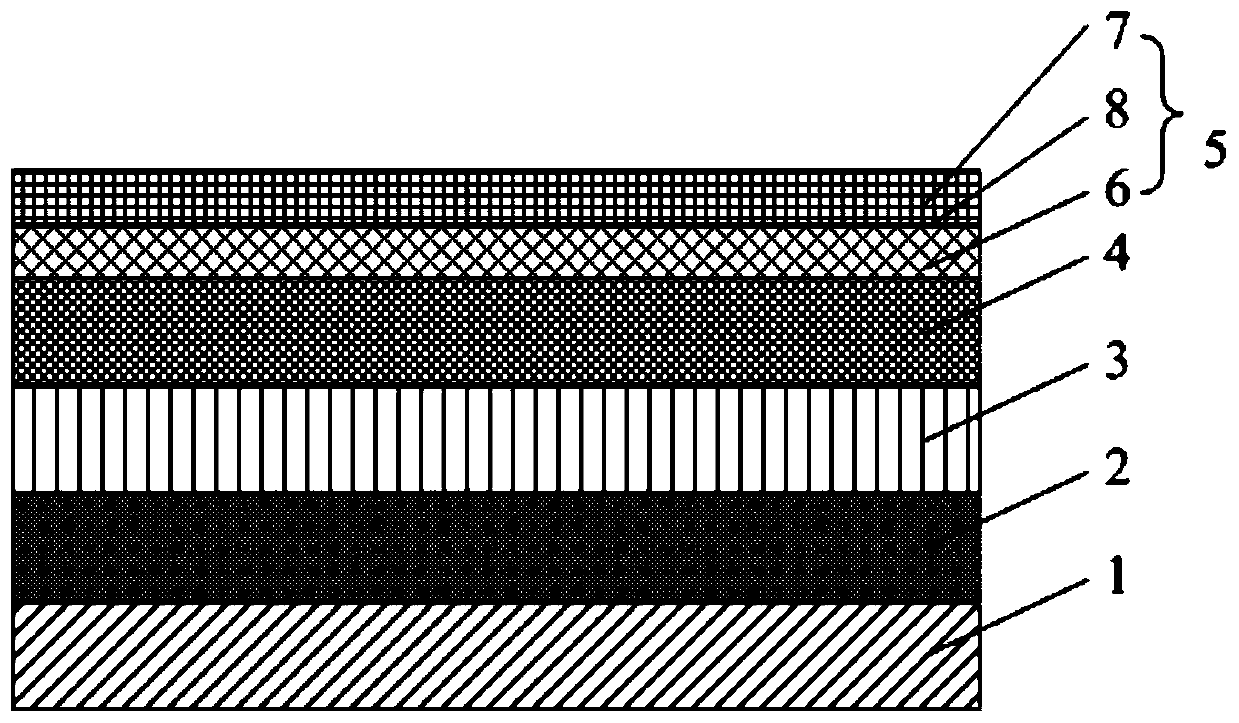

[0045] This embodiment provides a barrier type CIGS solar cell, see Figure 1 to Figure 8 , including a substrate 1 and a back electrode layer 2, a first absorption layer 3, a buffer layer 4 and a transparent surface electrode layer 5 laminated on the substrate 1 in sequence, wherein the transparent surface electrode layer 5 is made of indium zinc tin oxide (IZTO) .

[0046]Compared with the prior art, the barrier type CIGS solar cell provided in this embodiment adopts IZTO to replace the common material ITO of the transparent surface electrode layer 5. Since the structure density of IZTO is better than that of ITO, and the water vapor barrier performance of IZTO is higher than that of ITO, therefore , the transparent surface electrode layer 5 made of IZTO can better protect the moisture-sensitive buffer layer 4 and the first absorber layer 3, thereby improving the working stability of the above-mentioned barrier type CIGS solar cell.

[0047] Considering that the light trans...

Embodiment 2

[0071] This embodiment provides a method for preparing a barrier type CIGS solar cell, comprising the following steps:

[0072] Step 1: sequentially forming a back electrode layer, a first absorption layer and a buffer layer on the substrate;

[0073] Step 2: forming a first surface electrode layer and a second surface electrode layer on the surface of the buffer layer;

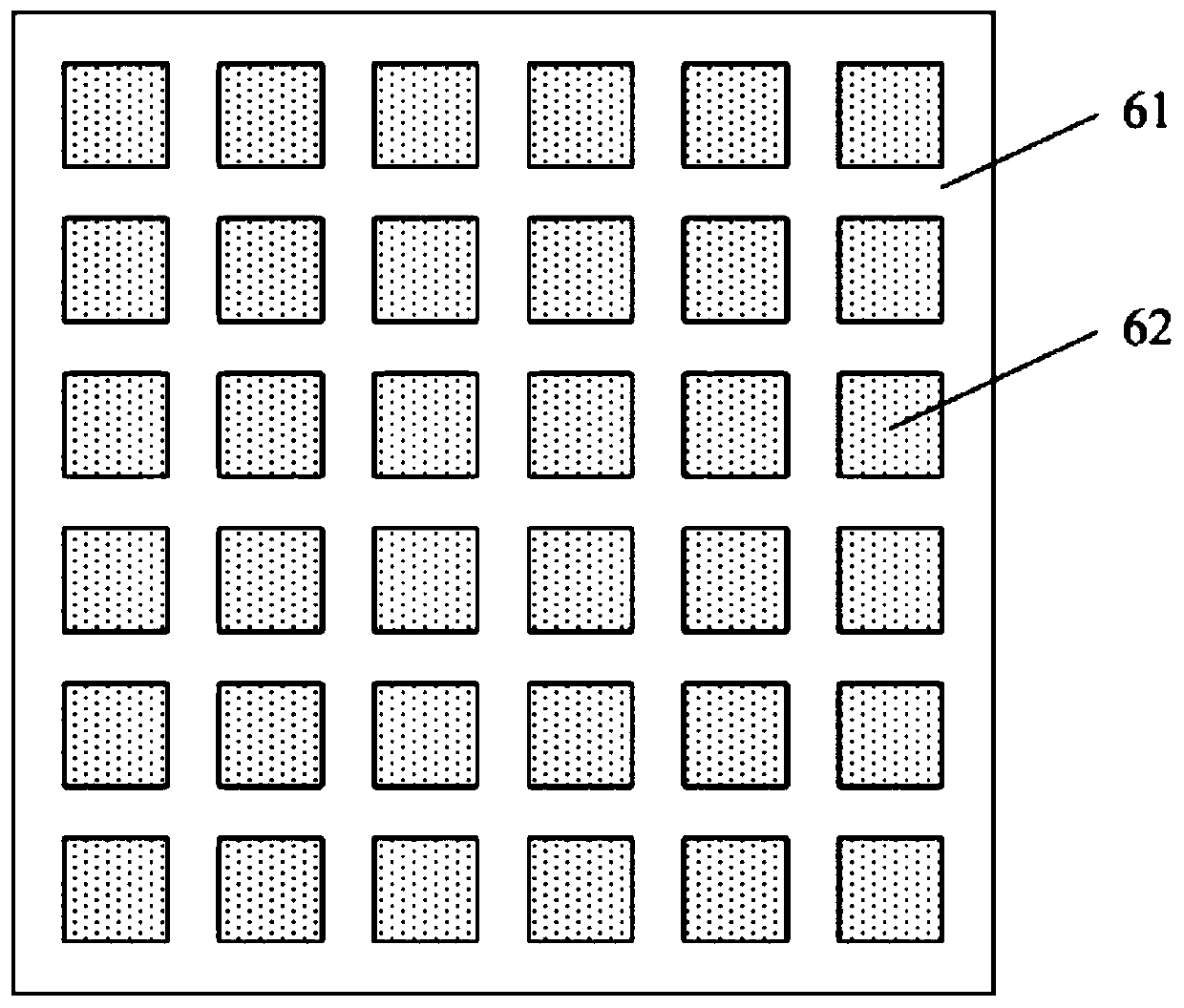

[0074] The first surface electrode layer is prepared by the following method: a layer of ITO layer is formed by a sputtering process, a plurality of IZTO accommodation grooves distributed in a matrix are formed on the ITO layer by an etching process, and a plurality of IZTO accommodation grooves are formed by a sputtering process. The first IZTO region is formed in the center, and the unetched part of the ITO layer is the first ITO region.

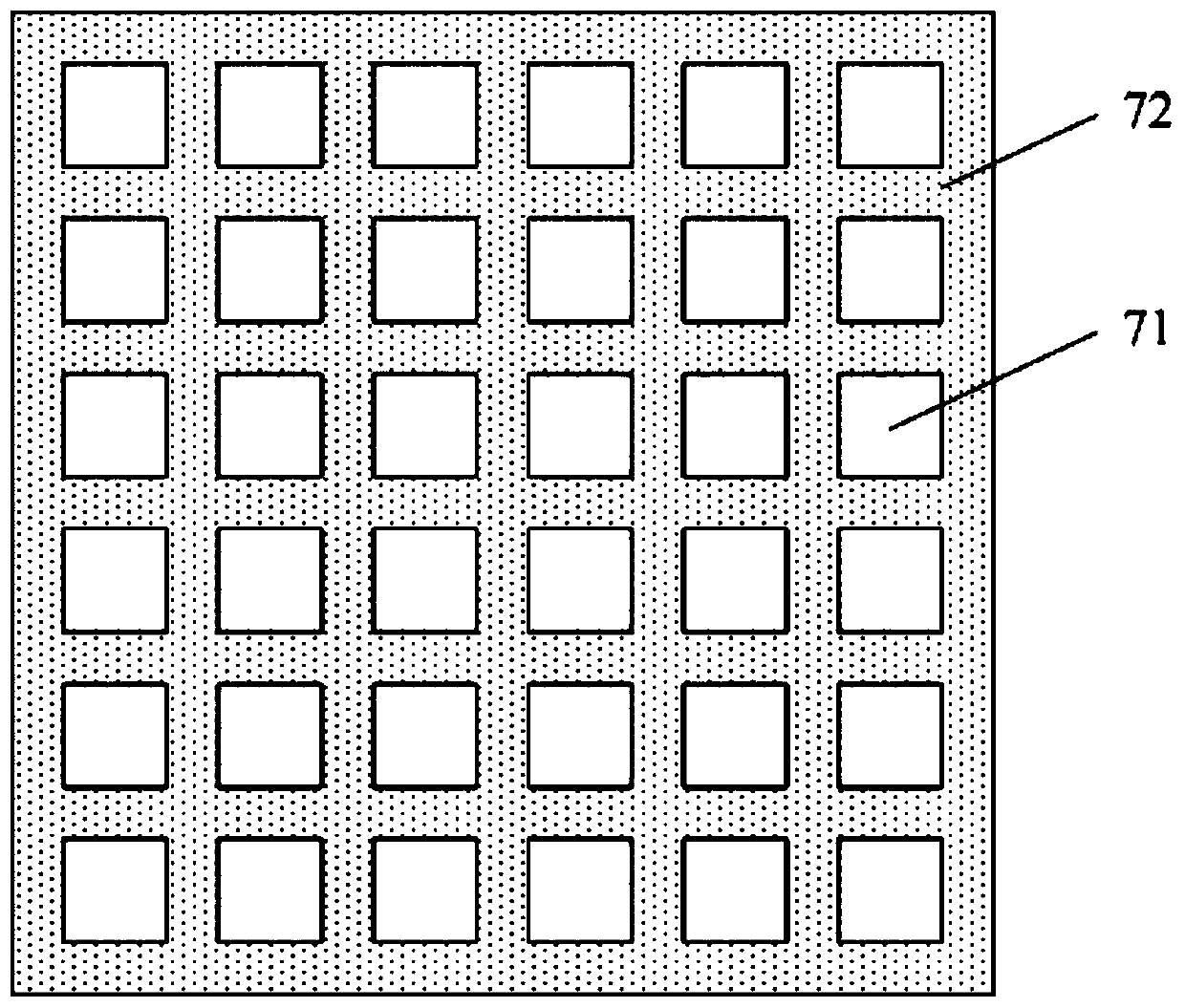

[0075] The second surface electrode layer is prepared by the following method: a layer of IZTO layer is formed by sputtering process, a plurality of ITO accommodation gr...

Embodiment 3

[0096]This embodiment provides a packaging structure for thin-film solar cells, which is rectangular and includes a protective film, a structural film and a back film pressed from top to bottom, and a CIGS solar cell is located between the structural film and the back film; usually In some cases, in order to facilitate processing, CIGS solar cells are generally made into rectangles, and the core object of packaging is CIGS solar cells, so the packaging structure is rectangular. The size of the structural film is the same as that of the CIGS solar cell; the area of the back film is larger than that of the CIGS solar cell; the protective film includes a main body and an edge, the main body is the same size as the CIGS solar cell, and the edges are arranged on the four sides of the main body and integrated with the main body. The edge seal tightly covers the structural film and the sides of the CIGS solar cell and is pressed against the back film. In the packaging structure, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com