Light photovoltaic module

A photovoltaic module, lightweight technology, applied in the field of solar cells, can solve the problems of anti-load performance verification, battery failure, module output power attenuation, etc., to achieve the effect of improving anti-PID performance, reducing logistics costs, and improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

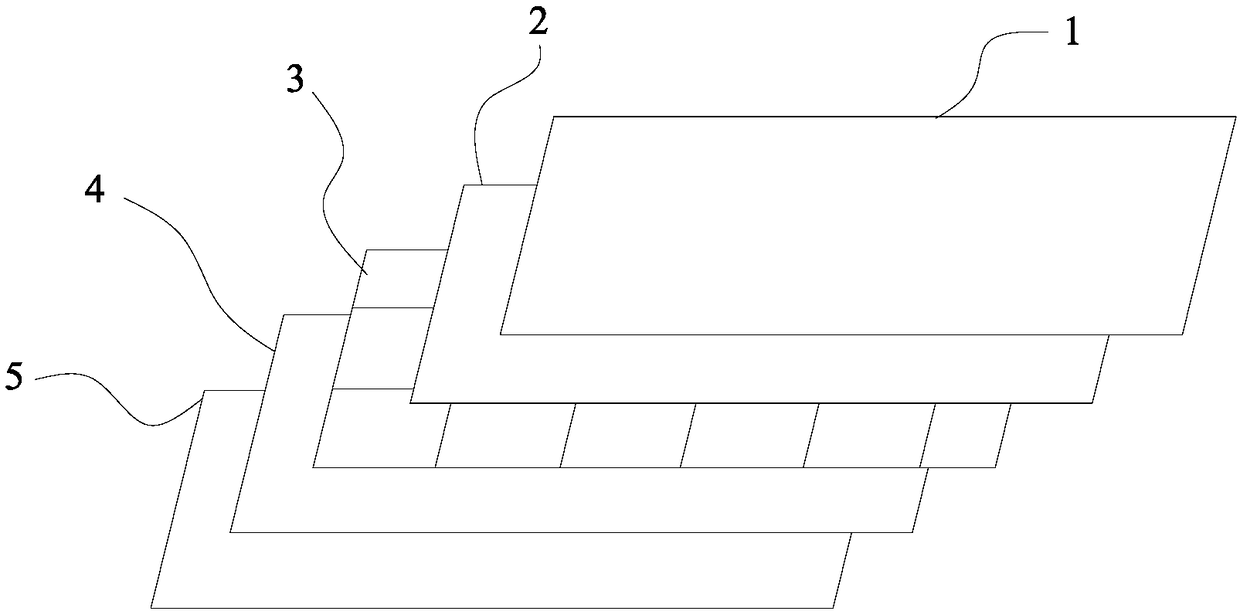

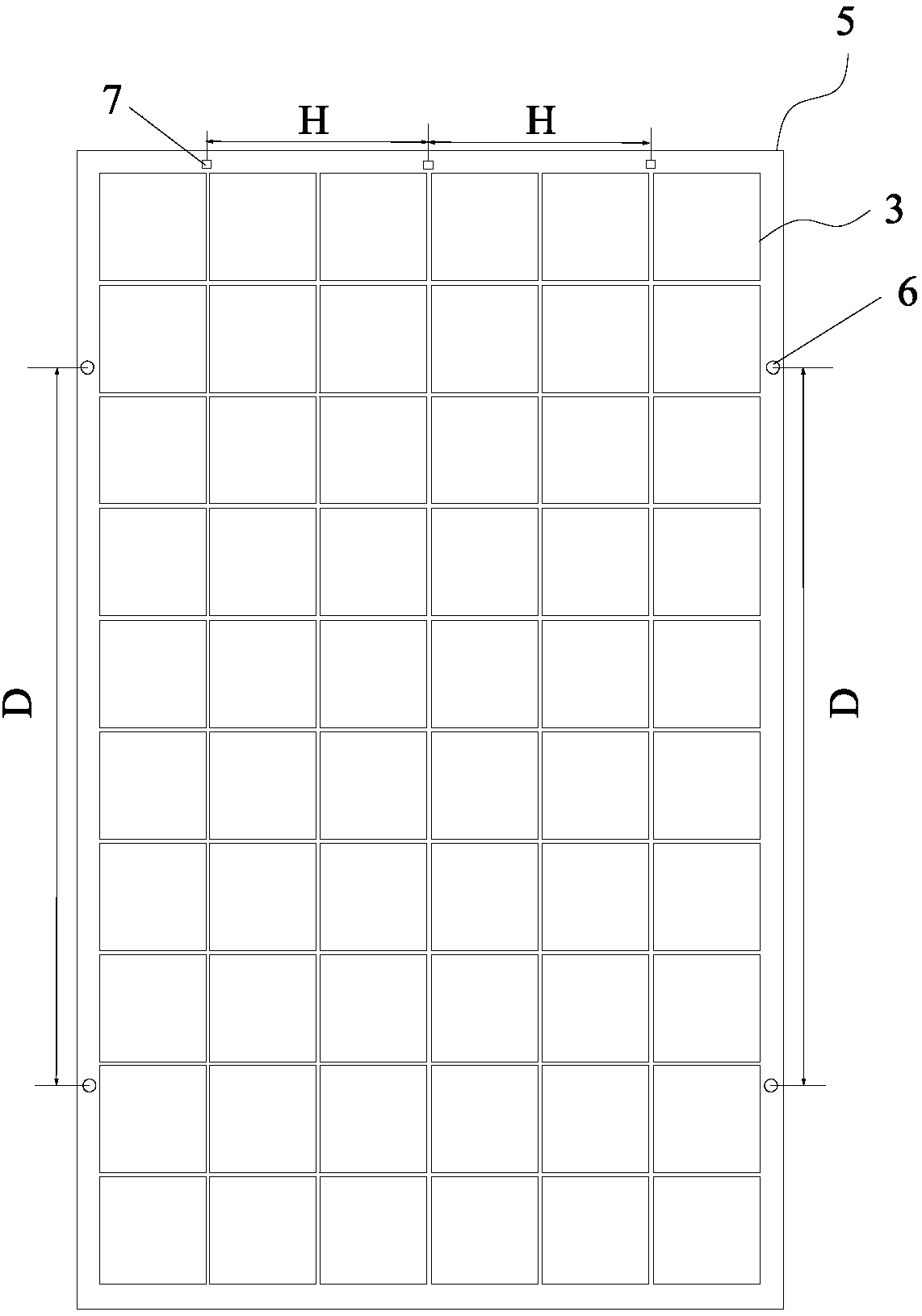

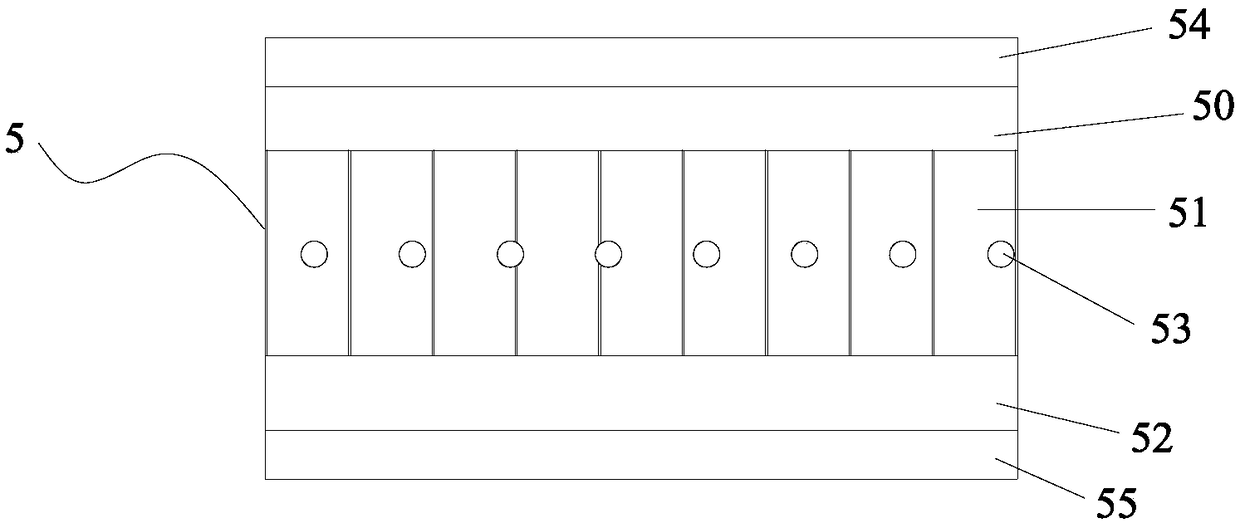

[0060] Such as Figure 1~4 As shown, the lightweight photovoltaic module provided by this embodiment includes a transparent front plate 1, a first encapsulation layer 2, a solar cell sheet 3, a second encapsulation layer 4 and a back plate 5 which are sequentially stacked. The first substrate layer 50, the honeycomb core layer 51 and the second substrate layer 52 are set, and the first substrate layer 50 and the honeycomb core layer 51, the second substrate layer 52 and the honeycomb core layer 51 are respectively bonded by an adhesive, The first substrate layer 50 is located between the second encapsulation layer 4 and the honeycomb core layer 51 .

[0061] In this example, the first substrate layer 50 is a metal layer, and the lightweight photovoltaic module further includes a first insulating layer 54 disposed between the first substrate layer 50 and the second encapsulation layer 4 . The thickness of the first insulating layer 54 is 30 micrometers.

[0062] In this examp...

Embodiment 2

[0070] The lightweight photovoltaic module provided in this embodiment differs from that of Embodiment 1 in that: the transparent front plate 1 is a composite film of polyvinyl fluoride and PET.

Embodiment 3

[0072] The difference between the lightweight photovoltaic module provided in this embodiment and Embodiment 1 is that the materials of the first substrate layer 50, the honeycomb core layer 51, and the second substrate layer 52 of the back plate 5 are respectively reinforced epoxy resin, Such as commercially available epoxy resin honeycomb panels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com