Method for preparing PID-resisting film

A thin-film and double-film technology, which is applied in final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve the problems of increased battery failure rate, increased control difficulty, poor PID performance, etc., and achieves obvious results. Easy to operate, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] For a 156x156mm polysilicon wafer, the preparation process of this embodiment is as follows:

[0017] (1) On the light-receiving surface of the silicon wafer after conventional texturing and diffusion, UV equipment (CDA flow rate 5slm, lamp power 20%, temperature: 25°C) is used to prepare a silicon wafer with a thickness of 2nm and a refractive index on the surface of the silicon wafer. 1.46 silicon oxide film;

[0018] (2) On the silicon oxide film, use the seven-star tube PECED equipment to deposit a silicon nitride film under the conditions of a temperature of 450°C, a total flow rate of ammonia and silane of 7000SCCM, and a power of 6500W. The specific film thickness range is controlled at 70nm, and the refractive index is controlled. In 2.10.

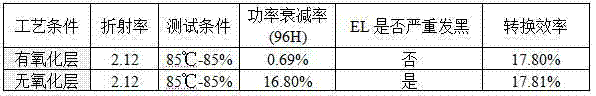

[0019] (3) The film thickness of the prepared silicon oxide and silicon nitride double-layer film is 82nm, and the refractive index is 2.12; and then a solar cell is made through a follow-up conventional process. The perfor...

Embodiment 2

[0024] For a 156x156mm polysilicon wafer, the preparation process of this embodiment is as follows:

[0025] (1) On the silicon wafer after conventional texturing and diffusion, the seven-star tube PECVD is adopted to use the seven-star tube PECVD with high RF power (about 5.5kw), N 2 O:SiH 4 The volume ratio is 7:1, and the silicon oxide film is prepared on the surface of the silicon wafer, the film thickness is controlled at 25nm, and the refractive index is controlled at 1.6;

[0026] (2) On the silicon oxide or silicon oxynitride film, use seven-star tube PECVD with high RF power (about 7kw), NH 3 :SiH 4 =7:1, the silicon nitride film thickness is controlled at 55nm, and the refractive index is controlled at 2.08;

[0027] (3) The total film thickness of the prepared silicon oxide thin film and silicon nitride thin film bilayer film is 82 nm, and the refractive index is 2.12.

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com