Crystalline silicon solar cell and preparation method thereof

A technology of solar cells and crystalline silicon, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that the refractive index of thin-film aluminum oxide materials cannot be achieved, the application cannot be implemented, and cannot be implemented.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

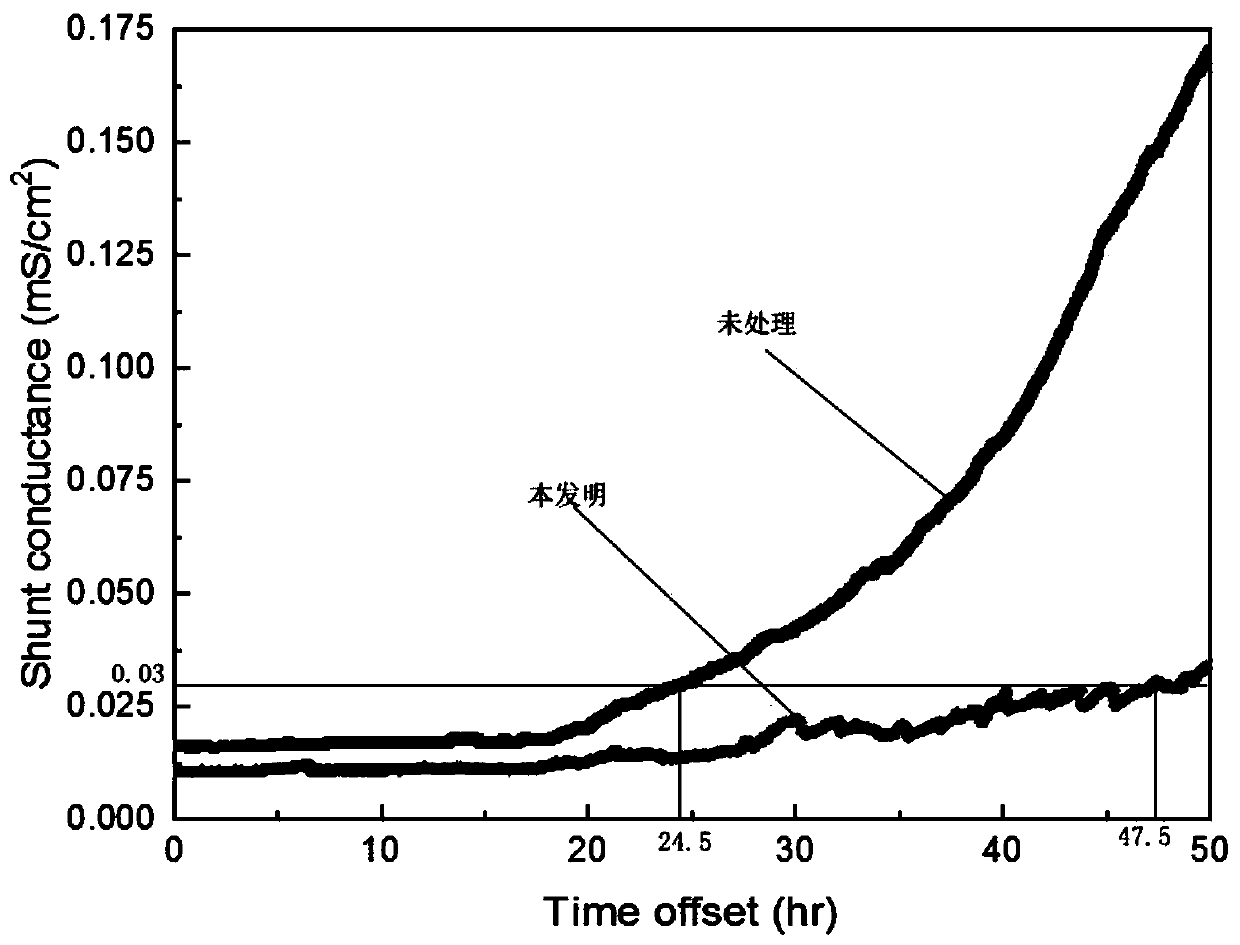

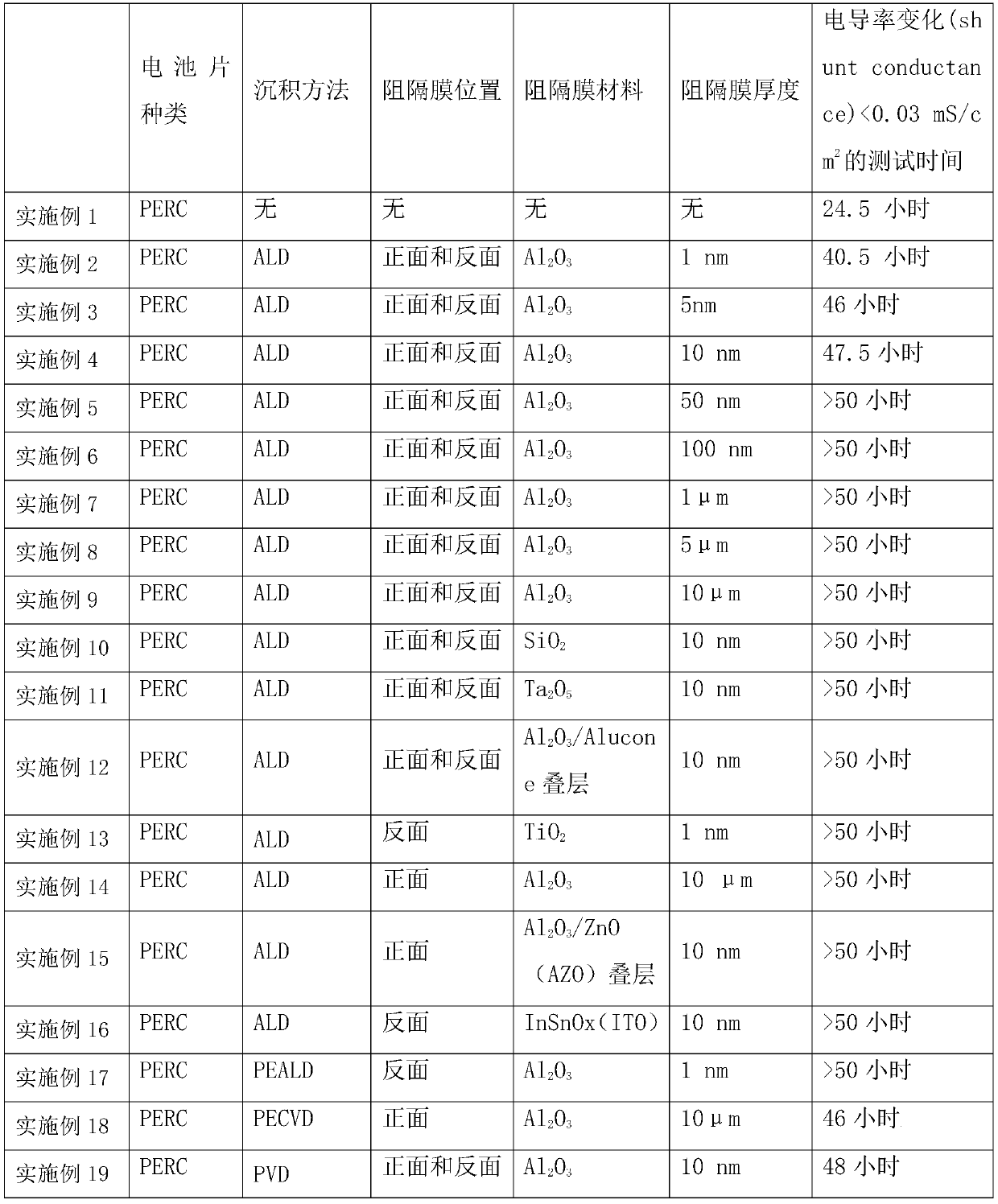

[0034] Embodiment 1 introduces a finished crystalline silicon solar cell that has not been treated by the present invention, and other embodiments will use it as a comparative example to prove the effect of the present invention. The test result curve is as figure 1 shown.

Embodiment 2-9

[0036] In Examples 2-9, PERC cells were double-sided Al by atomic layer deposition (ALD) equipment 2 o 3Coating, wherein the substrate temperature is 200°C, the pressure is 2-20mbar, the inert gas N 2 As carrier gas and purge gas, the flow rate is 400-2000sccm. Step ① uses trimethylaluminum as precursor A, the pulse duration is 0.5-3s; step ② uses N 2 Purification, the duration is 1-4s; step ③ uses water as precursor B, the duration is 1-4s; step ④ uses N 2 Purification, duration 2-6s. The plating rate was 0.12 nm / cycle. Alternate feed, grow layer by layer, control the number of cycles to reach the target thickness.

[0037] The Al obtained by ellipsometry 2 o 3 The refractive index of the film was tested, and the refractive index was 1.625.

[0038] The anti-PID effect of the battery is shown in the corresponding part of Table 1. Wherein the test curve of embodiment 4 is as figure 1 shown.

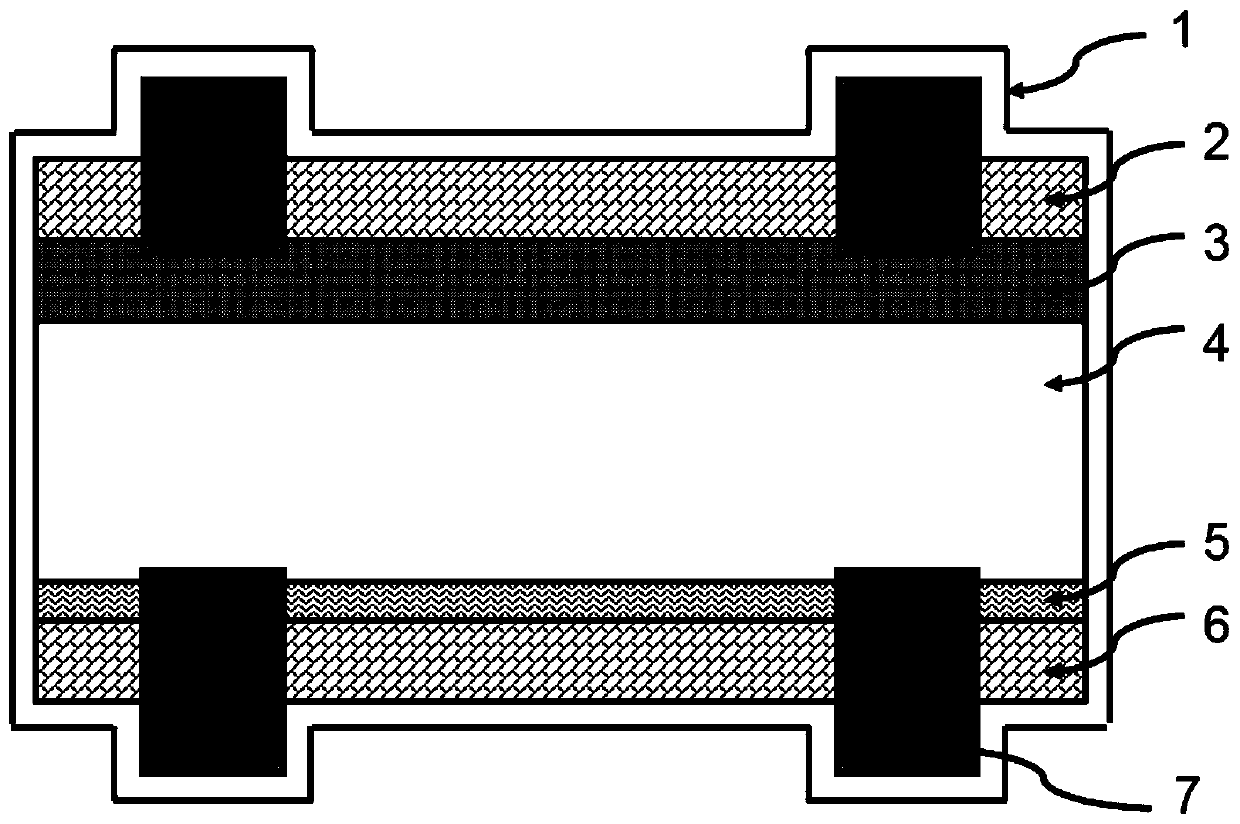

[0039] Gained crystalline silicon solar cell, its structure is as follows ...

Embodiment 10-16

[0041] In Examples 10-16, one or both sides of the PERC battery are coated with various materials as raw materials by atomic layer deposition (ALD) equipment, similar to Examples 2-9, wherein the substrate temperature is 200°C , the pressure is 2-20mbar, choose N 2 As carrier gas and purge gas, the flow rate is 400-2000sccm. Step ① use trimethylaluminum as precursor A, pulse duration 0.5-3s; step ② use N 2 Purification, duration 1-4s; step ③ use water as precursor B, duration 1-4s; step ④ use N 2 Purification, the duration of purification is 2-6s. Alternate feed, grow layer by layer, control the number of cycles to reach the target thickness. It can be adjusted according to different materials.

[0042] By controlling the deposition time, crystalline silicon solar cells with different barrier film thicknesses can be obtained, and the anti-PID effect is shown in the corresponding part of Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com