Anti-PID POE adhesive film special for photovoltaic double-glass assembly packaging and preparation method thereof

A double-glass component and photovoltaic technology, applied in photovoltaic power generation, film/sheet without carrier, adhesive, etc., can solve the problems of poor anti-PID effect, high volume resistivity, low water vapor transmission rate, etc., and achieve improved electrical insulation Effects of performance, expansion of the scope of use, and improvement of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

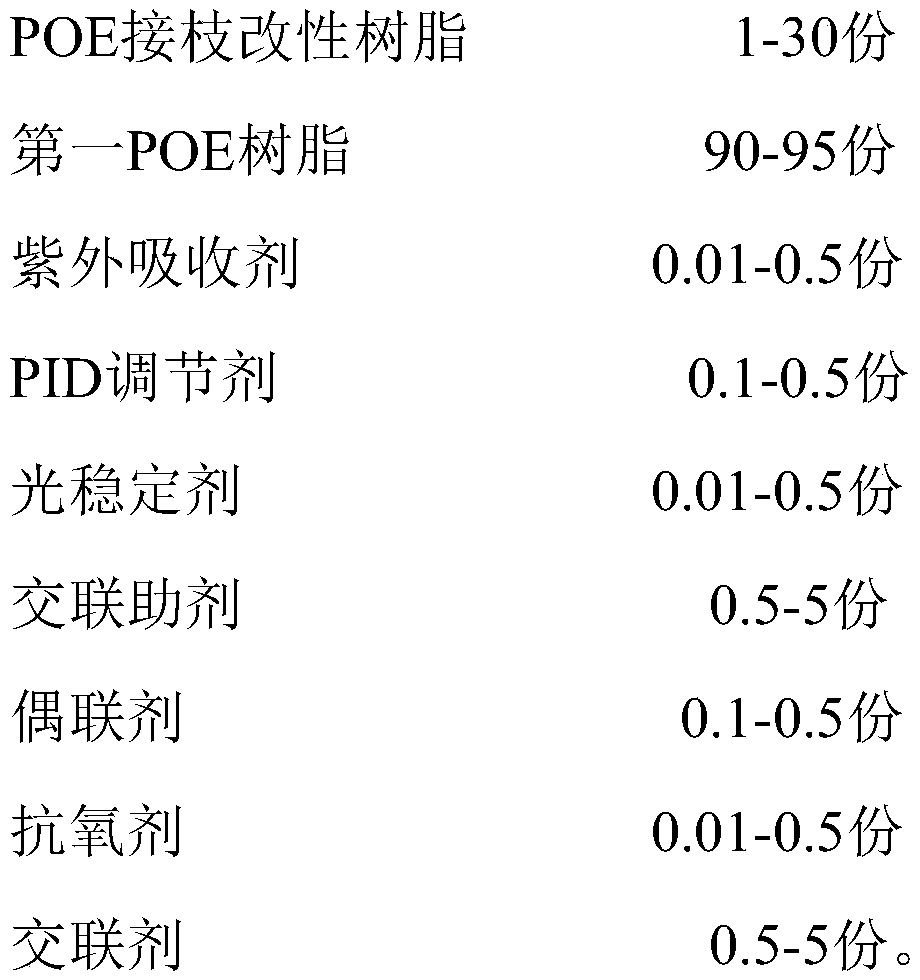

[0033] A special anti-PID POE adhesive film for photovoltaic double-glass module packaging, including the following raw materials in parts by weight:

[0034]

[0035] The preparation method of the PID regulator comprises the following steps: the nano-rare earth oxide Re 2 o 3 Weigh the proportion with the analytically pure oxide according to the weight ratio of 0.8:0.6, disperse it with a ball mill, place it in a vacuum drying oven at 110°C for pretreatment for 6 hours, take it out, and put the sample at a stirring speed of 750r / min and a nitrogen flow rate of 0.9 Dissolve in 1:1 hydrochloric acid at L / min state, dilute with distilled water until there is no white precipitate, then heat and co-precipitate with oxalic acid at a weight ratio of 1:1, then place the mixed solution for 22 hours to filter, wash, and dry to obtain PID regulator; more preferably, the analytically pure oxidation is made of Bi 2 o 3 , SiO 2 、Al 2 o 3 and MIO in a weight ratio of 0.8:0.6:0.1:0....

Embodiment 2

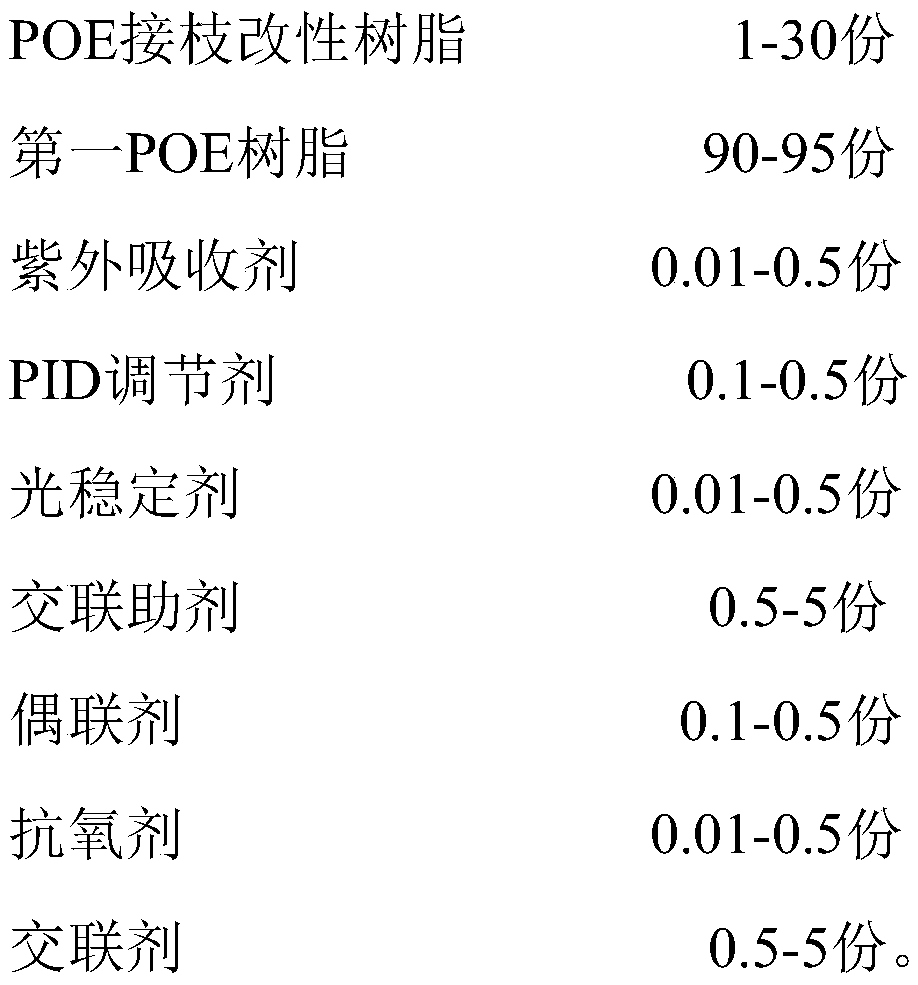

[0051] A special anti-PID POE adhesive film for photovoltaic double-glass module packaging, including the following raw materials in parts by weight:

[0052]

[0053] The preparation method of the PID regulator comprises the following steps: the nanometer rare earth oxide La 2 o 3 (Where Re=La, Pr, Nd, Sm, Eu, Gd) and the analytically pure oxides are weighed according to the weight ratio of 0.9:0.7, dispersed by a ball mill, and then placed in a 115°C vacuum oven for pretreatment for 6.5h , take it out, dissolve the sample in 1:1 hydrochloric acid at a stirring speed of 775r / min and a nitrogen flow rate of 0.95L / min, dilute it with distilled water until no white precipitate is present, and then heat it together with oxalic acid at a weight ratio of 1:1. Precipitation, after which the mixed solution is placed for 23h to filter, wash, and dry to obtain a PID regulator; more preferably, the analytically pure oxidation is made of Bi 2 o 3 , SiO 2 、Al 2 o 3 and MIO in a w...

Embodiment 3

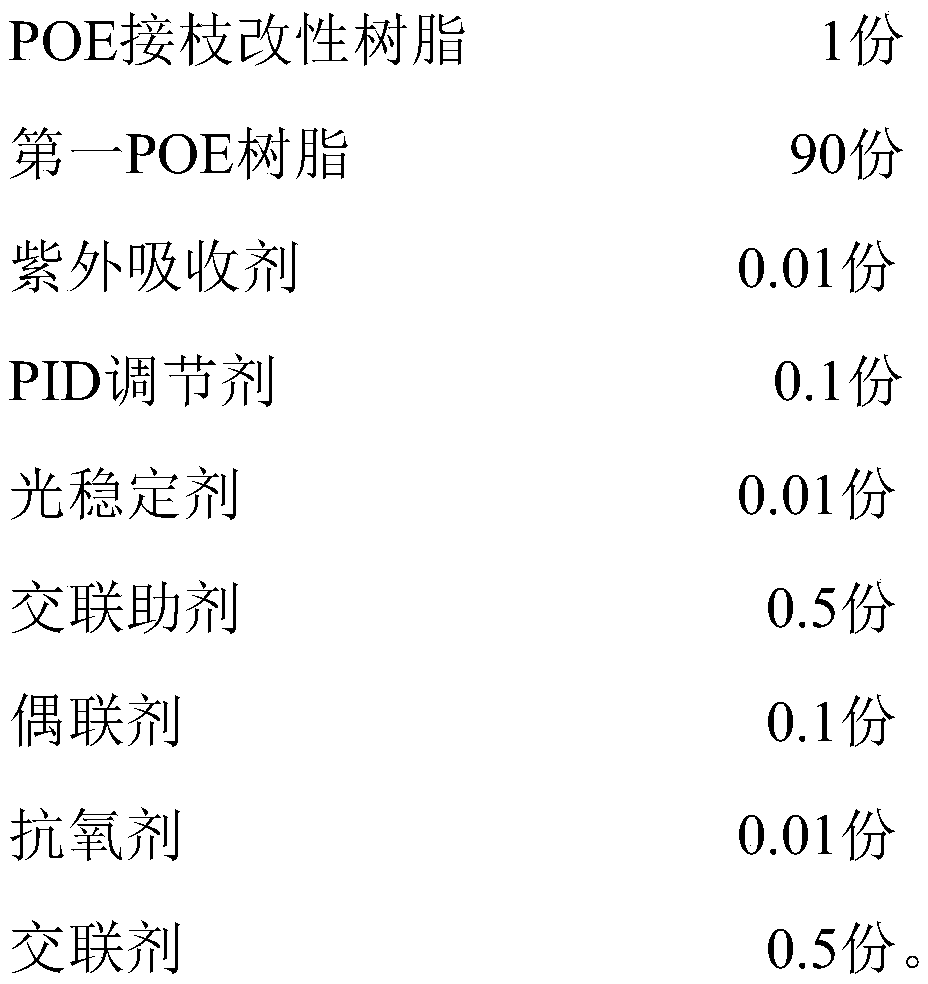

[0069] A special anti-PID POE adhesive film for photovoltaic double-glass module packaging, including the following raw materials in parts by weight:

[0070]

[0071] The preparation method of the PID regulator comprises the following steps: the nanometer rare earth oxide Pr 2 o 3 Weigh the proportion with the analytically pure oxide according to the weight ratio of 1.0.2:0.8, use a ball mill to disperse it, place it in a vacuum drying oven at 120°C for 7 hours, take it out, and put the sample at a stirring speed of 800r / min and nitrogen Dissolve in 1:1 hydrochloric acid at 1L / min, dilute with distilled water until there is no white precipitate, then heat and co-precipitate with oxalic acid at a weight ratio of 1:1, then place the mixed solution for 24 hours to filter, wash, and dry to obtain PID regulator; more preferably, the analytically pure oxidation is made of Bi 2 o 3 , SiO 2 、Al 2 o 3 and MIO in a weight ratio of 1.0:0.8:0.3:0.6.

[0072] Described POE graft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com