Method for preparing anti-potential induced degradation solar cell

A potential-induced decay, solar cell technology, applied in the field of solar cells, can solve the problems of graphite boat and furnace tube damage, poor compactness of the silicon dioxide layer, and high proportion of bad battery appearance, and achieves improved compactness, improved yield, and improved resistance to The effect of PID performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar elements or elements having the same or similar functions throughout. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

[0027] The production equipment of the anti-potential induced decay solar cell according to the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

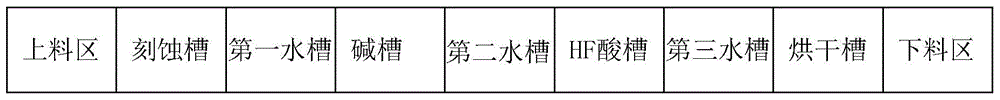

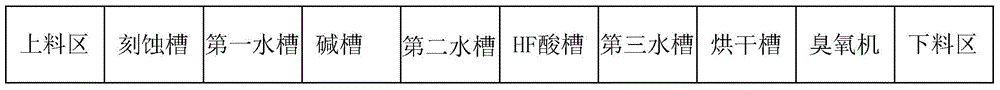

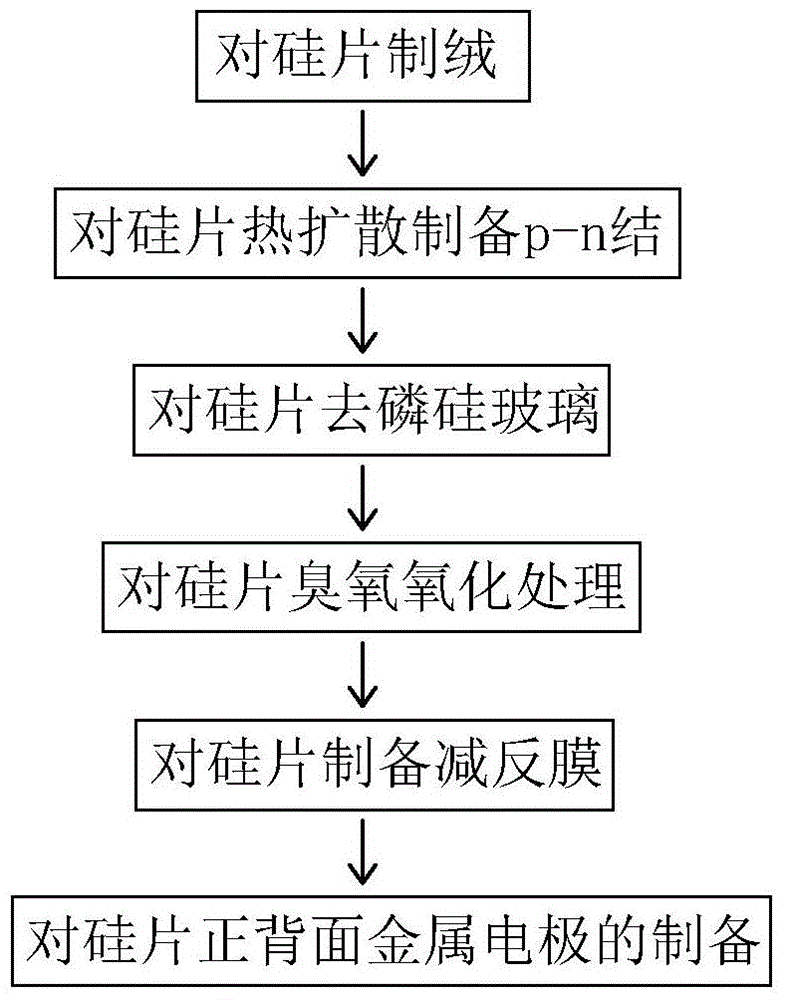

[0028] State-of-the-art de-PSG devices such as figure 1 As shown in the figure, the silicon wafer 3 goes through the feeding area, the etching tank, the first water tank, the alkali tank, the second water tank, the HF acid tank, the third water tank, the drying tank and the unlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com