Tubular PECVD storage boat preheating device for crystalline silicon solar cell and coating method

A technology of solar cells and crystalline silicon, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of affecting the output of tubular PECVD, depleting oxygen and compressing air, and ozone leakage, etc., to achieve improved passivation Effect, shortened process run time, effect of eliminating heating steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

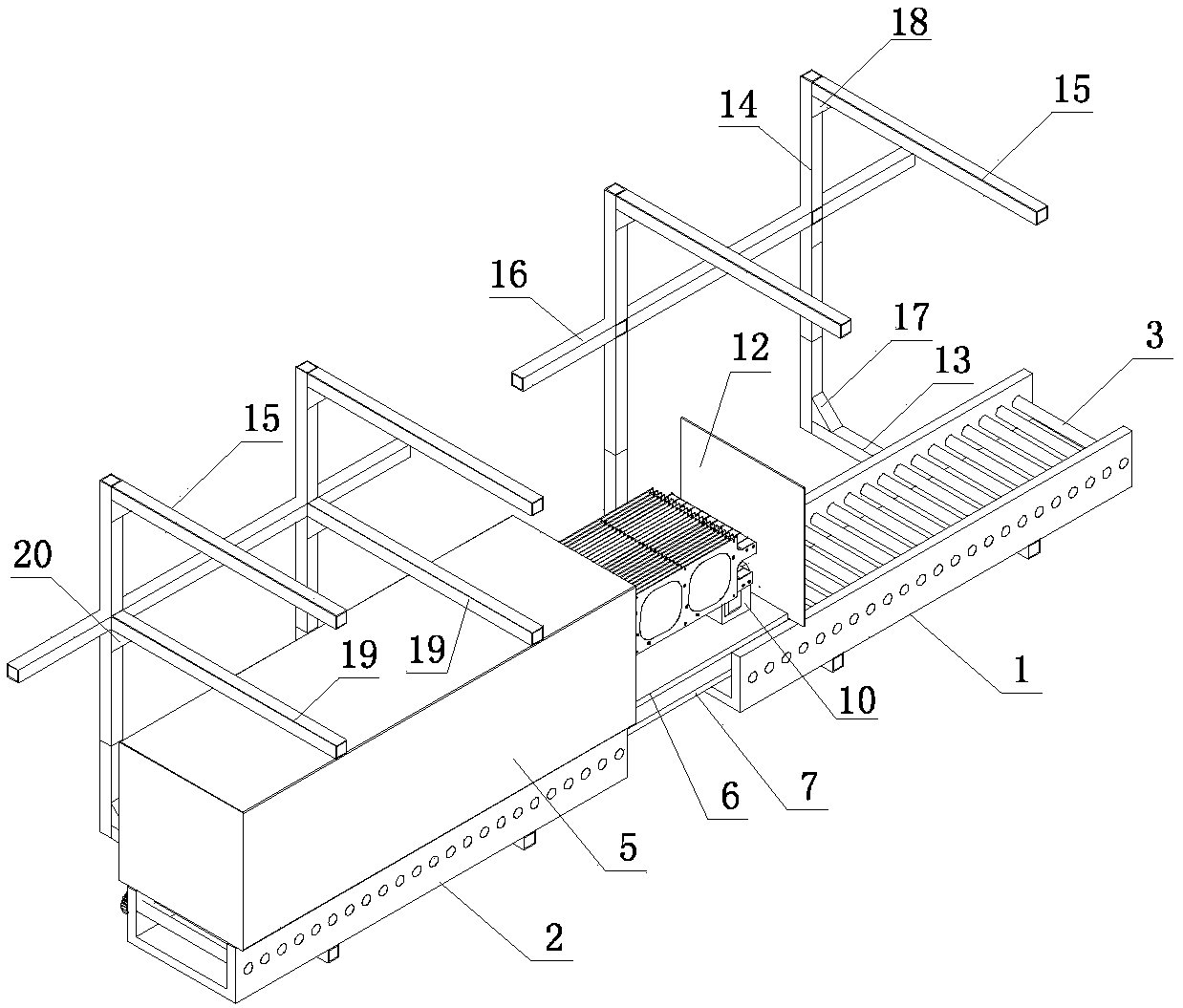

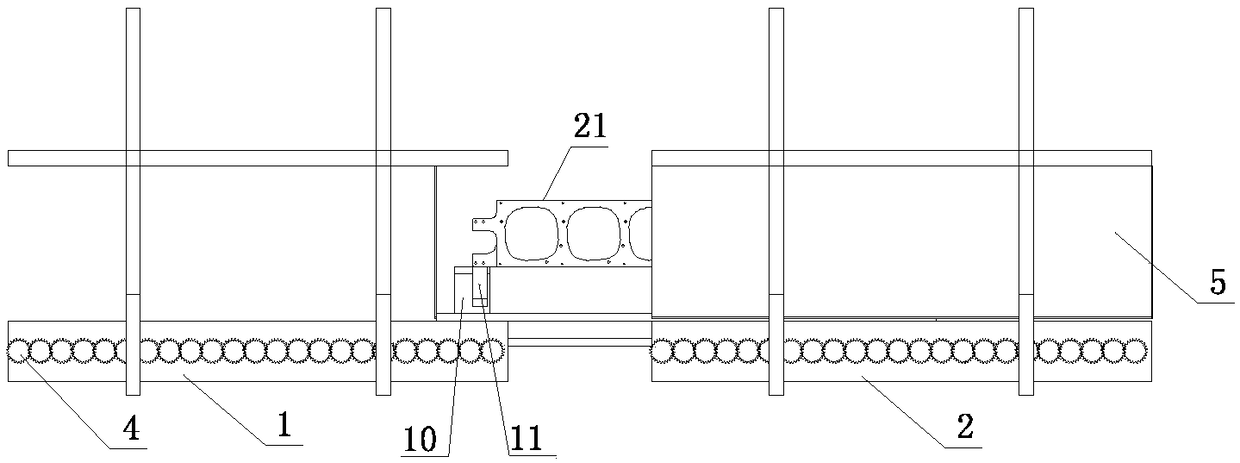

[0060] In order to further illustrate the technical means and effects that the present invention takes to achieve the predetermined invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, a kind of crystalline silicon solar cell tube type PECVD preheating boat storage device and The coating method, its specific implementation, features and effects, are described in detail below.

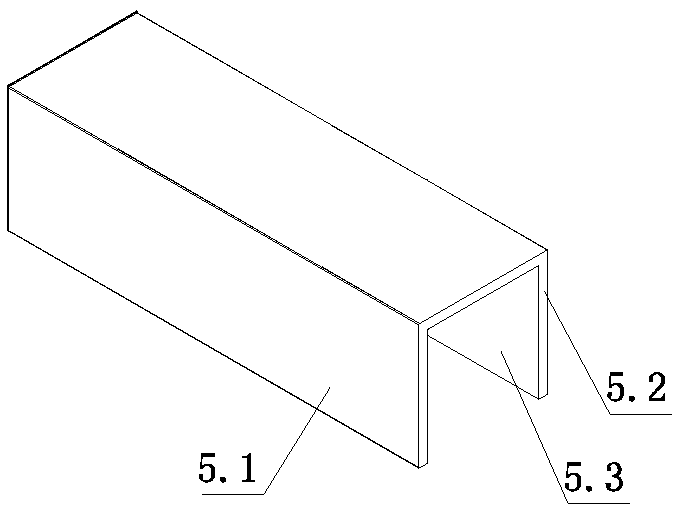

[0061] The preheating boat storage device of the present invention includes a transmission track A and a transmission track B, the transmission track A and the transmission track B are respectively fixed on the first fixed frame and the second fixed frame, and the center of the transmission track A and the transmission track B The axes are located on the same straight line, and the preferred solution is: the dimensions of the transmission track A and the transmission track B are the same.

[0062] A plurality of transmission rollers 3 are arranged on the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com