Anti-PID heat conduction glue film, photovoltaic assembly and photovoltaic power generation system

A thermally conductive adhesive film and photovoltaic module technology, applied in photovoltaic power generation, semiconductor devices, circuits, etc., can solve problems such as poor anti-PID performance, material aging, and low output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

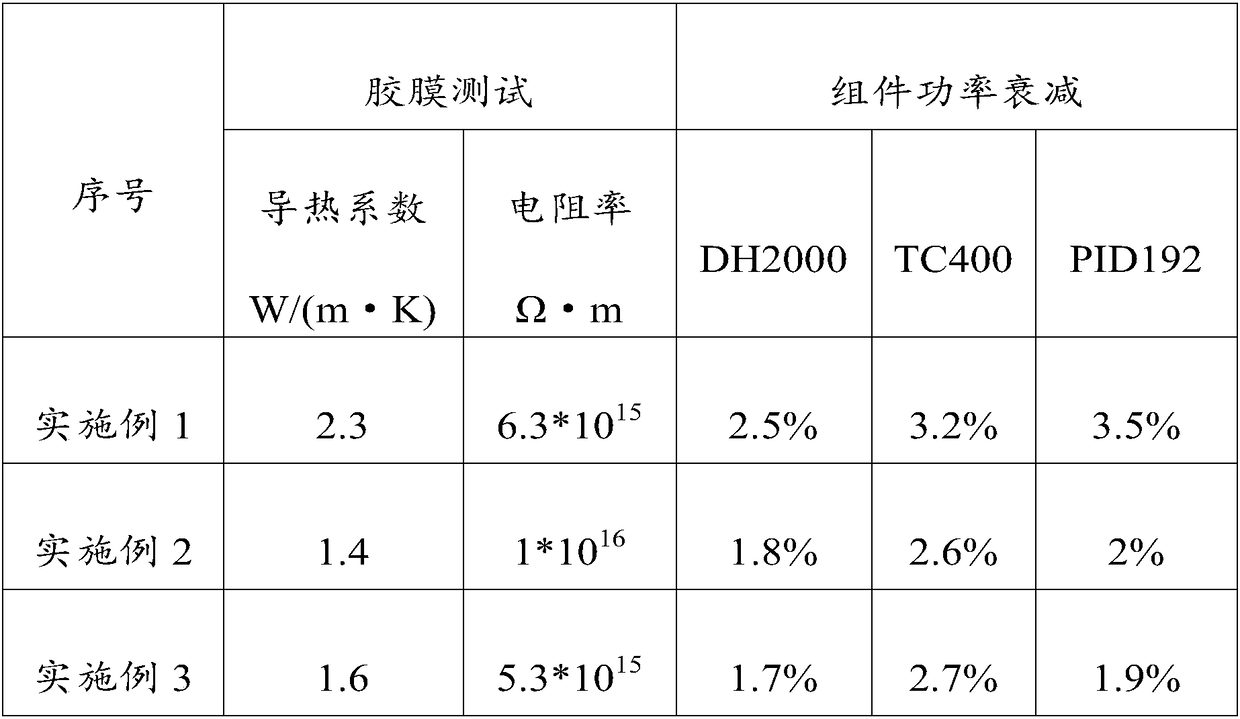

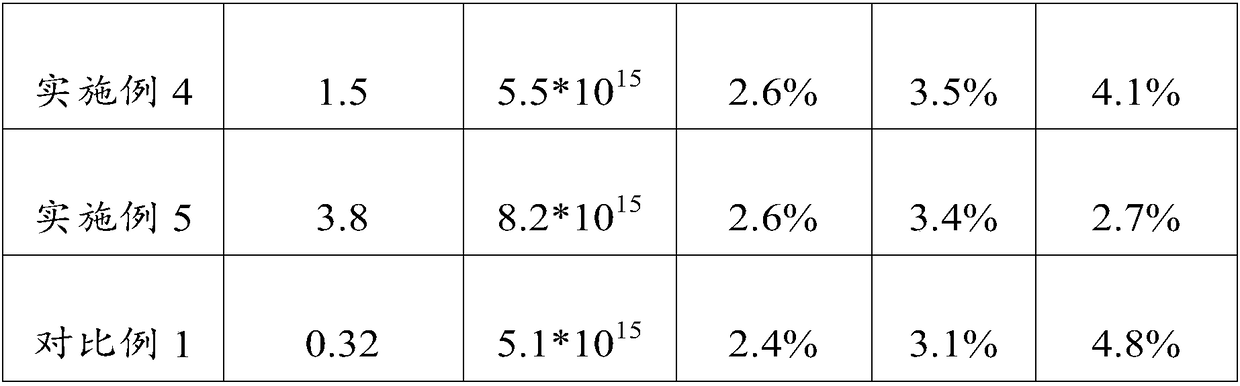

Embodiment 1

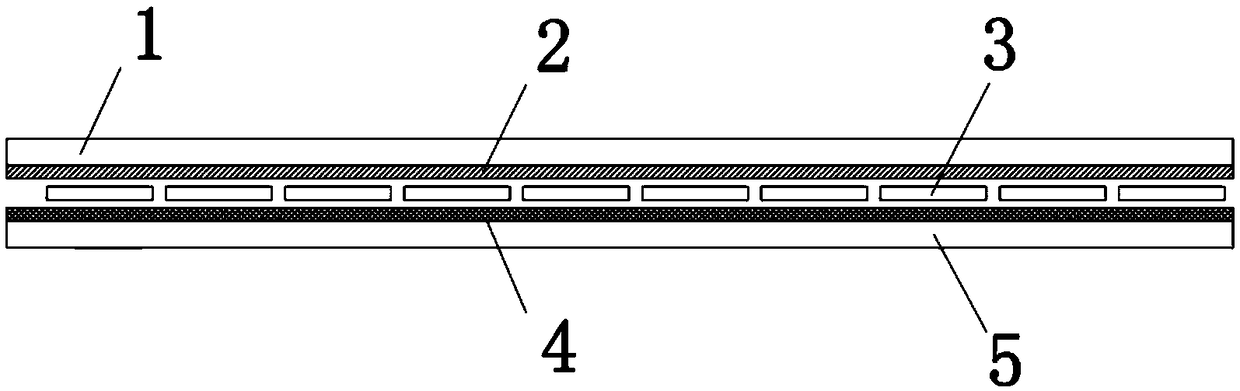

[0062] A photovoltaic module, which includes an upper cover plate 1, a first adhesive film 2, the battery 3, the anti-PID thermally conductive adhesive film and the back plate 5, which are sequentially stacked. The first adhesive film 2 is bonded between the upper cover plate 1 and the battery 3 , and the anti-PID thermally conductive adhesive film is bonded between the battery 3 and the back plate 5 .

[0063] Wherein, the upper cover plate 1 is a heat-strengthened glass cover plate, the first adhesive film 2 is an EVA film, the battery 3 is a battery string, and the back plate 5 is TPT.

[0064] The material of the film body of the anti-PID thermally conductive adhesive film is EVA, the shell material of the core-shell particles is polyethylene, and the core material of the core-shell particles is aluminum oxide. The mass percentage of the core-shell particles in the anti-PID heat-conducting adhesive film is 15%, the particle diameter of the core-shell particles is 2 μm, and...

Embodiment 2

[0066] A photovoltaic module, which is different from Embodiment 1 in that: the first adhesive film 2 is a POE film, the material of the adhesive film body of the anti-PID heat-conducting adhesive film is POE, and the back plate 5 is heat-strengthened glass.

Embodiment 3

[0068] A photovoltaic module, which is different from Embodiment 1 in that: the first adhesive film 2 is a PVB film, the material of the film body of the anti-PID heat-conducting adhesive film is PVB, and the back plate 5 is heat-strengthened glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com