Three-layer co-extrusion composite adhesive film for packaging photovoltaic module and preparation method thereof

A photovoltaic module encapsulation and three-layer co-extrusion technology, applied in photovoltaic power generation, adhesives, electrical components, etc., can solve the problems of poor water vapor barrier, poor anti-polarization ability, shortening the service life of components, etc. PID performance, good water vapor barrier performance, and the effect of avoiding service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

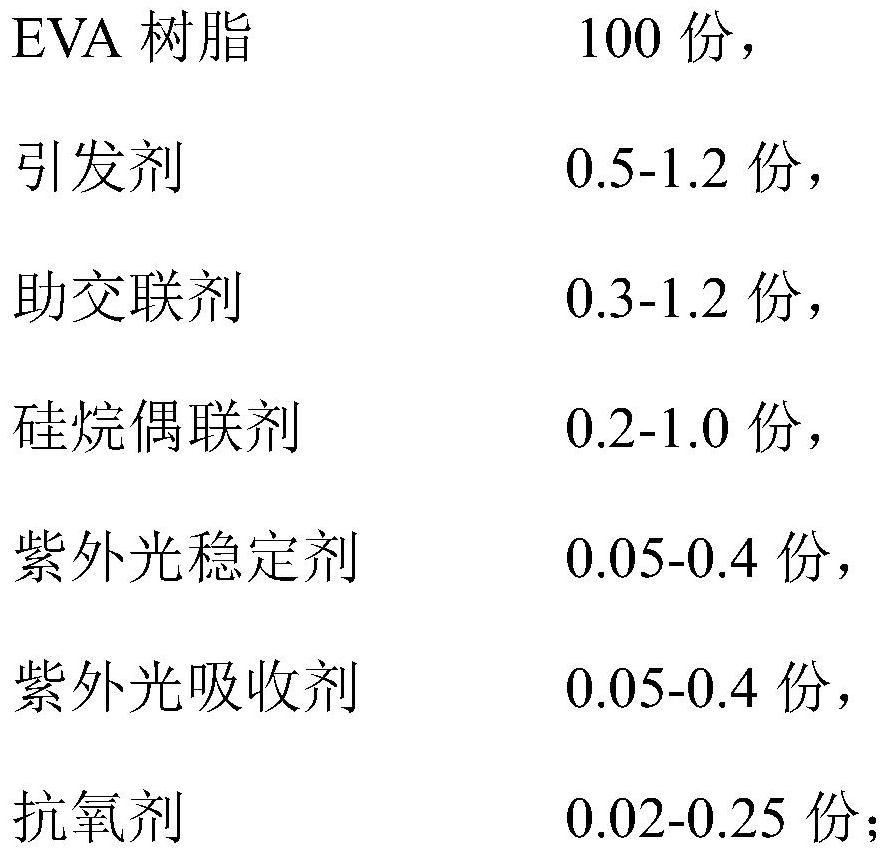

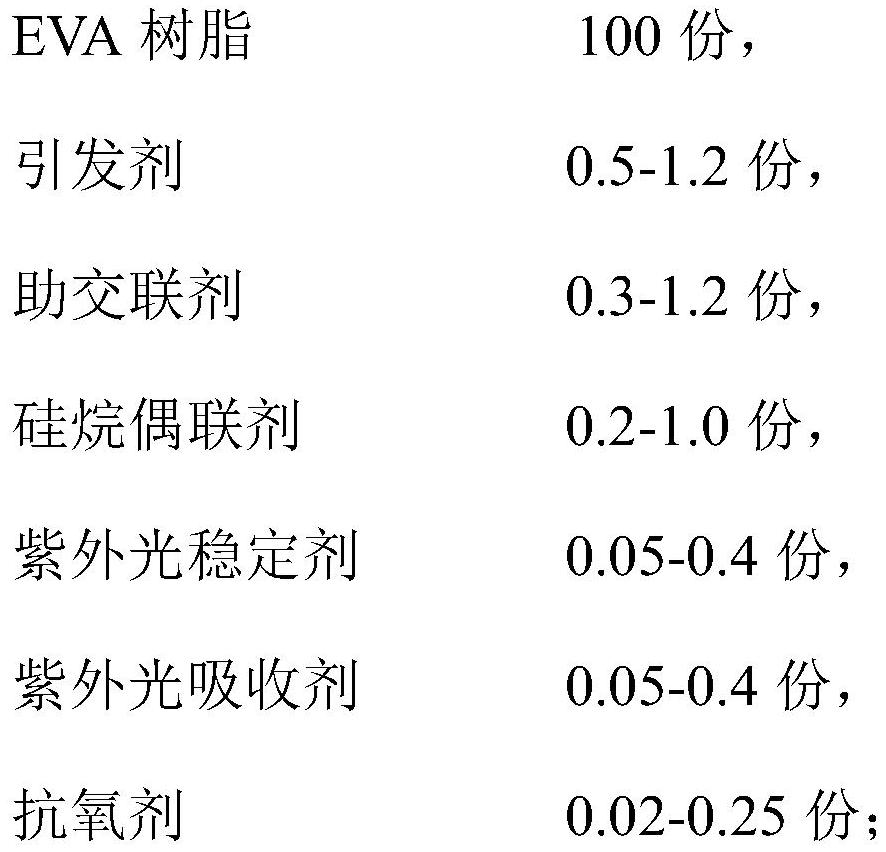

[0037] (1) 100 parts of EVA resin (melt flow rate is 25g / 10min, light transmittance>90%, volume resistivity>1.0×10 15 , melting temperature is 69°C, VA content 25%), 0.7 parts of tert-butyl peroxy-2-ethylhexyl carbonate, 0.9 parts of tripropenyl isocyanurate, 0.3 parts of vinyl tri-tert-butoxysilane, 0.1 part of dihydroxy-tetra-n-octyl hydroxybenzophenone, 0.1 part of 2,2-dihydroxy-4-methoxybenzophenone, 0.05 part of tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionic acid] pentaerythritol ester is mixed evenly, pours in the feed bin of single-screw extruder, stand-by;

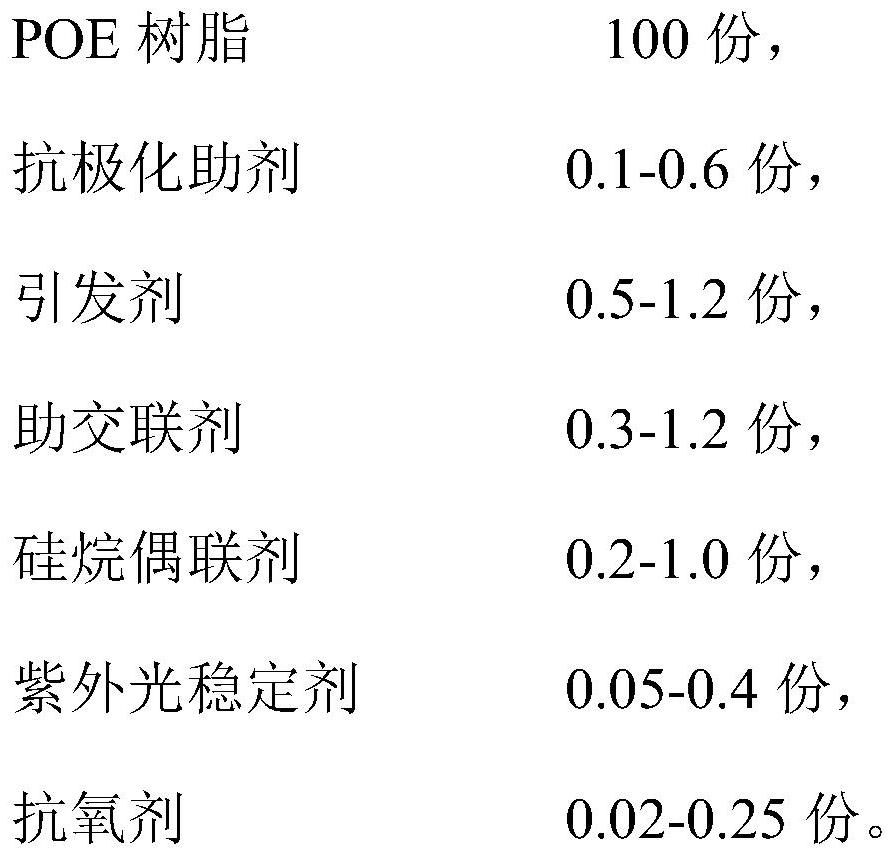

[0038] (2) 100 parts of POE resin (melt flow rate is 18g / 10min, light transmittance>90%, volume resistivity>1.0×10 16 , melting temperature is 61°C), 0.2 parts of trimethylolpropane trimethacrylate, 0.7 parts of tert-butyl peroxy-2-ethylhexyl carbonate, 0.9 parts of tripropenyl isocyanurate, 0.3 parts of ethylene Tri-tert-butoxysilane, 0.1 part of dihydroxy-tetra-n-octyl hydroxybenzophenone, 0.05 p...

Embodiment 2

[0042] (1) 100 parts of EVA resin (melt flow rate is 18g / 10min, light transmittance>90%, volume resistivity>1.0×10 15, melting temperature is 65°C, VA content 20%), 0.6 parts of 1,1'-bis(tert-butylperoxy)-3,3,5-trimethylcyclohexane, 0.8 parts of triallyl cyanurea Ester, 0.3 parts of γ-methacryloxypropyltrimethoxysilane, 0.15 parts of bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate, 0.15 Part of 2,2-dihydroxy-4-methoxybenzophenone, 0.1 part of n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, mix well, pour Put it into the silo of the single-screw extruder for use;

[0043] (2) 100 parts of POE resin (melt flow rate is less than 15g / 10min, light transmittance> 91%, volume resistivity> 1.0×10 16 , melting temperature is 59°C), 0.3 parts of pentaerythritol tetraacrylate, 0.6 parts of 1,1'-bis(tert-butylperoxy)-3,3,5-trimethylcyclohexane, 0.8 parts of triallyl Cyanurate, 0.3 part of γ-methacryloxypropyltrimethoxysilane, 0.15 part of bis(1,2,2,6,6-pentamethyl-4-pip...

Embodiment 3

[0047] (1) 100 parts of EVA resin (melt flow rate is 28g / 10min, light transmittance>90%, volume resistivity>1.0×10 15 , melting temperature is 68°C, VA content 28%), 0.8 parts of tert-butyl peroxycarbonate-2-ethylhexyl, 0.9 parts of tripropenyl isocyanurate, 0.3 parts of vinyl triisopropoxysilane , 0.1 part of 3,5-di-tert-butyl-4-hydroxy-hexadecyl benzoate, 0.15 part of 2,2-dihydroxy-4-methoxybenzophenone, 0.05 part of three (2,4 -di-tert-butylphenyl) phosphite is mixed evenly, poured in the single-screw extruder feed bin, stand-by;

[0048] (2) 100 parts of POE resin (melt flow rate is 18g / 10min, light transmittance>90%, volume resistivity>1.0×10 15 , melting temperature is 68°C, VA content 28%), 0.2 parts of trimethylolpropane triacrylate, 0.8 parts of tert-butyl peroxycarbonate-2-ethylhexyl ester, 0.9 parts of tripropenyl isocyanurate , 0.3 parts of vinyltriisopropoxysilane, 0.1 parts of 3,5-di-tert-butyl-4-hydroxy-hexadecyl benzoate, 0.05 parts of tris(2,4-di-tert-butylp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com