Anti-PID (potential induced degradation) polyolefin adhesive film for solar cell module

A solar cell and polyolefin technology, applied in electrical components, circuits, adhesives, etc., can solve the problems of polyolefin film softening and deformation, easy to reach around 80°C, battery displacement, etc., and achieve good anti-PID performance, good resistance PID characteristics, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

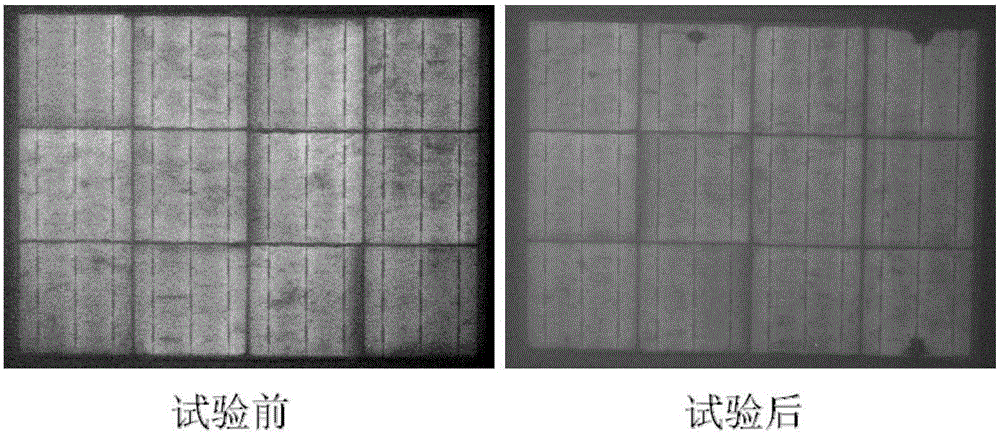

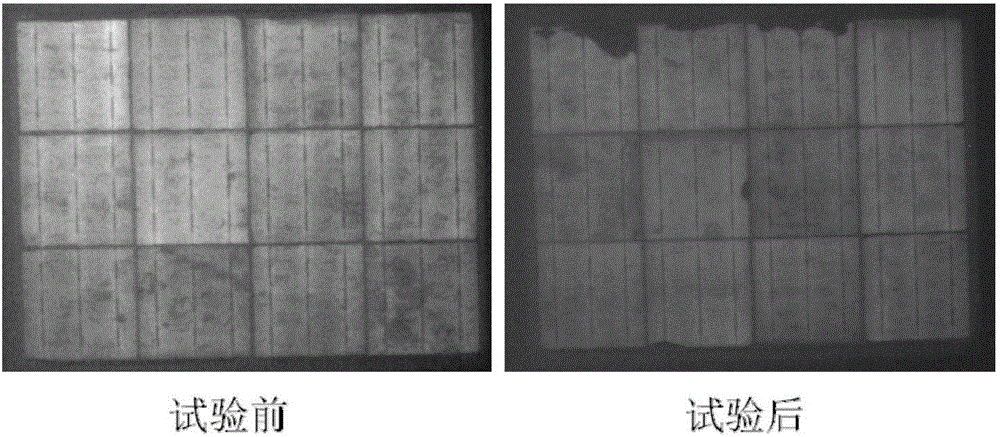

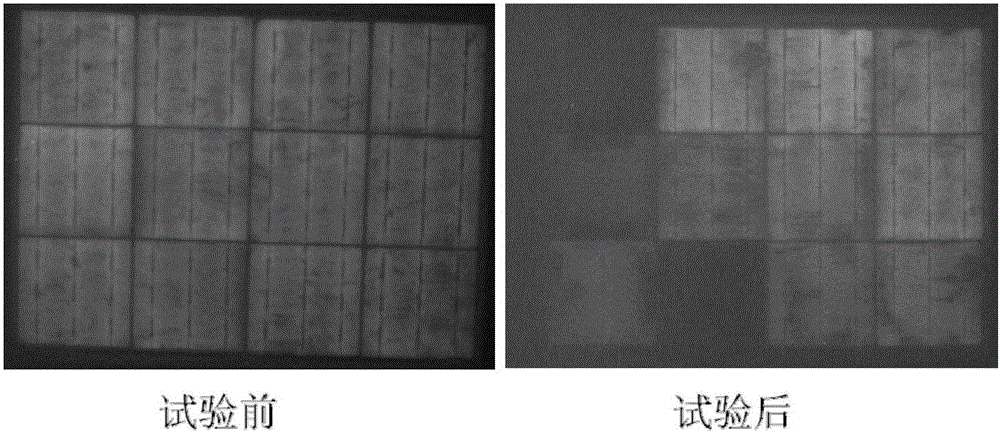

Image

Examples

Embodiment 1

[0041] A kind of anti-PID polyolefin adhesive film for solar cell module, described adhesive film is A / B / A three-layer structure film;

[0042] (1) Layer A adhesive film: 100 parts (parts by mass) of polyolefin resin [melt index (MI) is 18 g / 10 minutes (190 ° C, 2.16 kg), melting point is 76 ° C, American Dow Company, 8411] input In the high stirrer, add 1.0 parts of organic peroxide tert-butyl peroxycarbonate-2-ethylhexyl (Akema, Luperox TBEC), 2.0 parts of auxiliary crosslinking agent triallyl isocyanurate (Hunan Lide, TAIC), 0.5 part of silane coupling agent γ-methacryloxypropyl trimethoxysilane (Dow Corning, 6030), 0.2 part of UV absorber 2-hydroxy-4-n-octyloxydi Benzophenone (Beijing Institute of Addition Auxiliaries, GW531), 0.2 parts of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate (Beijing Addition Auxiliaries Research Institute, GW480), 0.2 parts of antioxidant dioctadecyl pentaerythritol diphosphite (Double Bond Chemical Industry, CHINOX618), stir...

Embodiment 2

[0046] The materials are the same as in Example 1, and the mass ratio of each layer A:B:A is 10:80:10 to obtain sample S2 with a thickness of 0.5 mm and a width of 1000 mm; the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com