EVA adhesive film with high water vapor barrier property

A water vapor barrier and adhesive film technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of low processing temperature, weak EVA water resistance, and reduced component efficiency. problems, to achieve the effect of enhancing the water vapor barrier performance, improving the heat and humidity resistance performance, and increasing the thermal stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

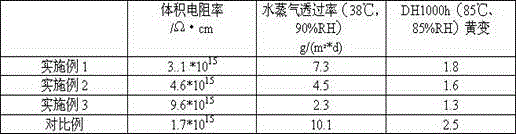

Embodiment 1

[0033] 100 parts of EVA resin with a vinyl acetate content of 28%, 1.0 parts of dicumyl peroxide, 0.5 parts of 3-allyl isocyanurate, β-3,5-di-tert-butyl-4-hydroxyphenyl ) n-octadecyl propionate, 0.5 parts of 2,2'-dihydroxy-4-methoxybenzophenone, .2 parts of bis(2,2,6,6-tetramethyl-4-piperidine base) sebacate, 0.5 parts of acetyl trimethylsilane, 3 parts of talc powder are mixed evenly through a mixer, put into a casting machine, and plasticized at 110°C for extrusion, stretching, traction, and winding Form an EVA film with a thickness of about 0.5mm.

Embodiment 2

[0035] 100 parts of EVA resin with a vinyl acetate content of 28%, 1.0 parts of dicumyl peroxide, 0.5 parts of 3-allyl isocyanurate, β-3,5-di-tert-butyl-4-hydroxyphenyl ) n-octadecyl propionate, 0.5 parts of 2,2'-dihydroxy-4-methoxybenzophenone, .2 parts of bis(2,2,6,6-tetramethyl-4-piperidine base) sebacate, 0.5 parts of acetyl trimethylsilane, 10 parts of talc powder are mixed evenly through a mixer, put into a casting machine, and plasticized, extruded, stretched, drawn, and rolled at 110 ° C. Form an EVA film with a thickness of about 0.5mm.

Embodiment 3

[0037] 100 parts of EVA resin with a vinyl acetate content of 28%, 1.0 parts of dicumyl peroxide, 0.5 parts of 3-allyl isocyanurate, β-3,5-di-tert-butyl-4-hydroxyphenyl ) n-octadecyl propionate, 0.5 parts of 2,2'-dihydroxy-4-methoxybenzophenone, .2 parts of bis(2,2,6,6-tetramethyl-4-piperidine Base) sebacate, 0.5 parts of acetic trimethylsilane, 15 parts of talc powder are mixed evenly through a mixer, put into a casting machine, and plasticized at 110°C for extrusion, stretching, traction, and winding. Form an EVA film with a thickness of about 0.5mm.

[0038] prior art embodiment

[0039] In 100 parts by mass of EVA resin with a vinyl acetate content of 28%, 1.0 parts of dicumyl peroxide, 0.5 parts of 3-allyl isocyanurate, β-3,5-di-tert-butyl-4-hydroxybenzene base) n-octadecyl propionate, 0.5 parts of 2,2'-dihydroxy-4-methoxybenzophenone, .2 parts of bis(2,2,6,6-tetramethyl-4-piper Pyridyl) sebacate, 0.5 parts of acetoxytrimethylsilane are mixed evenly by a mixer, put int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com