High-barrier environmental-friendly coating lined paper and manufacturing method thereof

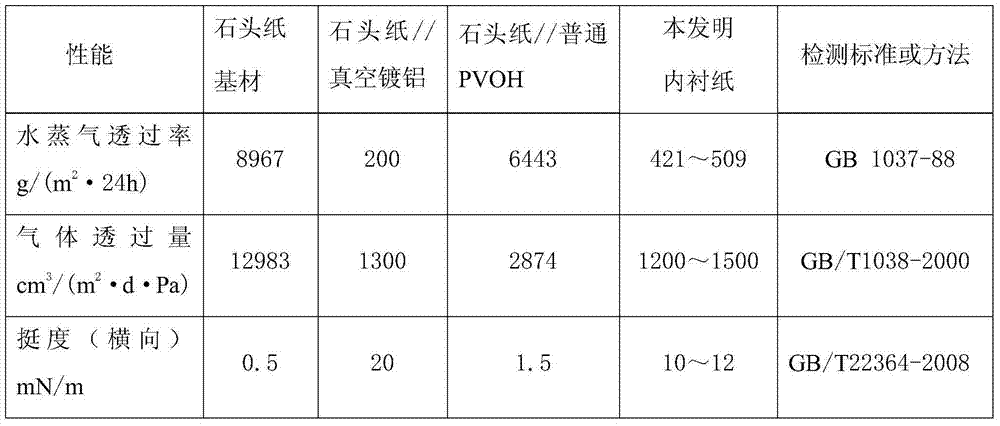

A manufacturing method and high-barrier technology, applied in chemical instruments and methods, devices for coating liquid on the surface, coatings, etc., can solve the problems of difficulty in meeting high-speed cigarette production requirements, low stiffness of inner lining paper, and high production costs , to achieve the effects of low cost, increased stiffness and strength, and improved water vapor barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 5.5% polyvinyl alcohol into 70% soft water, start stirring and heating, the temperature is 29°C, the speed is 120 rpm, make it evenly dispersed, then raise the temperature to accelerate the dissolution, and keep it for 0.7 hours when the temperature reaches 95°C After completely dissolving, the temperature is lowered, and when the temperature drops to 76°C, 7% defoamer is added. Then add 8% citronellal and 4% catalyst, raise the stirring speed to 110 rpm, keep the temperature constant for 4.5 hours, finally add 5.5% carbon nanofibers, stir until fully mixed. After the reaction is completed, the PVOH coating is obtained.

[0027] Under a constant unwinding tension of 15N, the roll-shaped stone paper base material is flattened to run continuously and stably. After preheating to make the surface temperature reach 35°C, pass the A layer of water-based ink is printed on the metal anilox roller, the number of printing roller lines is 50 lines / cm, and the amount of ink is...

Embodiment 2

[0030] Add 6.2% polyvinyl alcohol into 71% soft water, start stirring and heating, the temperature is 28°C, the speed is 145 rpm, make it evenly dispersed, then raise the temperature to accelerate the dissolution, and keep it for 0.5 hours when the temperature reaches 93°C After completely dissolving, lower the temperature. When the temperature drops to 75°C, add 3% defoamer. Then add 7% citronellal and 4.8% catalyst, increase the stirring speed to 100 rpm, keep the temperature constant for 2 hours, finally add 8% carbon nanofibers, stir until fully mixed. After the reaction is completed, the PVOH coating is obtained.

[0031] Under a constant unwinding tension of 13N, the roll-shaped stone paper base material is flattened into a continuous and stable operation. After preheating to make the surface temperature reach 39°C, pass the A layer of water-based ink is printed on the metal anilox roller, the number of printing roller lines is 45 lines / cm, and the amount of ink is 3.2g...

Embodiment 3

[0034] Add 6% polyvinyl alcohol into 72.5% soft water, start stirring and heating, the temperature is 31°C, the speed is 100 rpm, make it evenly dispersed, then raise the temperature to accelerate the dissolution, and keep it for 0.8 hours when the temperature reaches 90°C After completely dissolving, cool down, and when the temperature drops to 77°C, add 4.1% defoamer. Add 5.3% citronellal and 3.7% catalyst, increase the stirring speed to 130 rpm, keep the temperature constant for 4 hours, finally add 8.4% carbon nanofibers, stir until fully mixed. After the reaction is completed, the PVOH coating is obtained.

[0035] Under a constant unwinding tension of 18N, the roll-shaped stone paper base material is flattened to run continuously and stably. After preheating to make the surface temperature reach 37°C, it passes A layer of water-based ink is printed on the metal anilox roller, the number of printing roller lines is 60 lines / cm, and the amount of ink is 4.2g / m 2 , and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com