Photovoltaic encapsulation material EVA adhesive film resisting potential induced attenuation

A potential-induced attenuation, packaging material technology, applied in photovoltaic power generation, films/sheets without carriers, circuits, etc., can solve problems such as difficult to meet the service life of components, can not solve the problem of ion migration from the root, and eliminate passivation Phenomenon, stable and lasting excellent anti-PID performance, the effect of increasing molecular volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

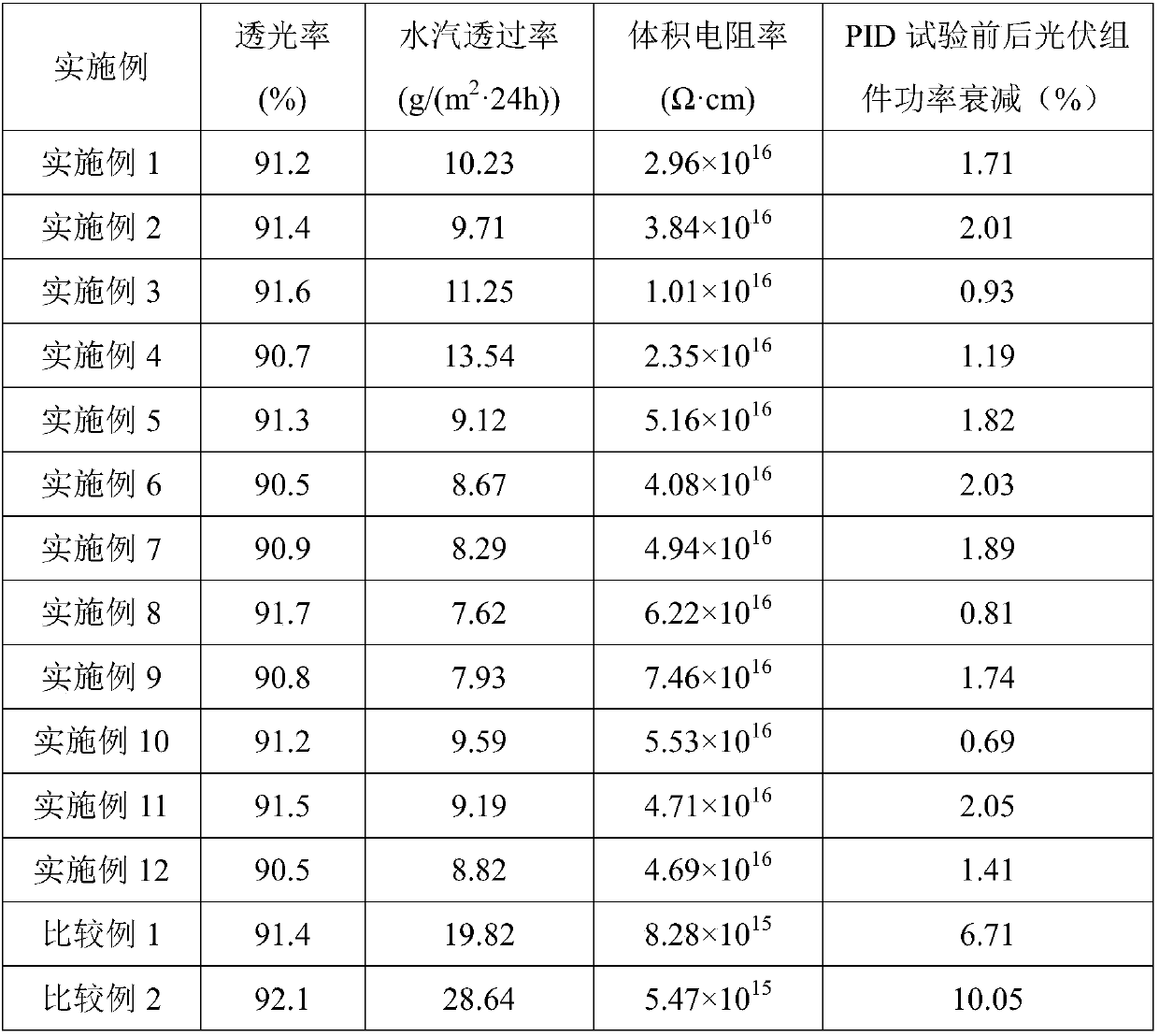

Examples

Embodiment 1

[0035] This embodiment provides a packaging material with anti-PID performance.

[0036] In this example, matrix resin: in terms of mass fraction, get 90% ethylene-vinyl acetate copolymer (vinyl acetate (VA) mass content is 20%, U.S. DuPont Company), 10% high melting point polyethylene (melting point 80 ℃). Based on 100 parts of the above-mentioned matrix resin by mass, add 0.8 parts of tert-butyl peroxyisopropyl carbonate, 0.8 parts of triethylene glycol dimethacrylate, 0.1 parts of 2-hydroxy-4-n-octyloxydiphenyl Methanone, 0.2 parts of silane coupling agent, 0.1 part of bis-2,2,6,6-tetramethylpiperidinol sebacate. The above-mentioned ethylene-vinyl acetate, the complex compound for absorbing sodium ions and other additives are pre-mixed, melt-extruded, cast into a film, cooled, cut and rolled, and the EVA glue is obtained. film, denoted as E-1.

Embodiment 2

[0038] In this example, matrix resin: in terms of mass fraction, get 90% ethylene-vinyl acetate copolymer (vinyl acetate (VA) mass content is 20%, U.S. DuPont Company), 10% high melting point polyethylene (melting point 80 ℃). Based on 100 parts of the above-mentioned matrix resin, add 1 part of symmetrical tetramethyl six-membered cucurbit ring, 0.8 part of tert-butyl peroxyisopropyl carbonate, 0.8 part of triethylene glycol dimethacrylate, 0.1 part of 2 -Hydroxy-4-n-octyloxybenzophenone, 0.2 part of silane coupling agent, 0.1 part of bis-2,2,6,6-tetramethylpiperidinol sebacate. The above-mentioned ethylene-vinyl acetate, the complex compound for absorbing sodium ions and other additives are pre-mixed, melt-extruded, cast into a film, cooled, cut and rolled, and the EVA glue is obtained. Film, denoted as E-2.

Embodiment 3

[0040] In this example, matrix resin: in terms of mass fraction, get 90% ethylene-vinyl acetate copolymer (vinyl acetate (VA) mass content is 20%, U.S. DuPont Company), 10% high melting point polyethylene (melting point 80 ℃). Based on 100 parts of the above-mentioned matrix resin by mass, add 1 part of calcium silicate, 0.8 part of tert-butyl peroxyisopropyl carbonate, 0.8 part of triethylene glycol dimethacrylate, 0.1 part of 2-hydroxy-4- N-octyloxybenzophenone, 0.2 part of silane coupling agent, 0.1 part of bis-2,2,6,6-tetramethylpiperidinol sebacate. The above-mentioned ethylene-vinyl acetate, the complex compound for absorbing sodium ions and other additives are pre-mixed, melt-extruded, cast into a film, cooled, cut and rolled, and the EVA glue is obtained. Film, denoted as E-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com