Patents

Literature

36results about How to "Reduce acetic acid content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

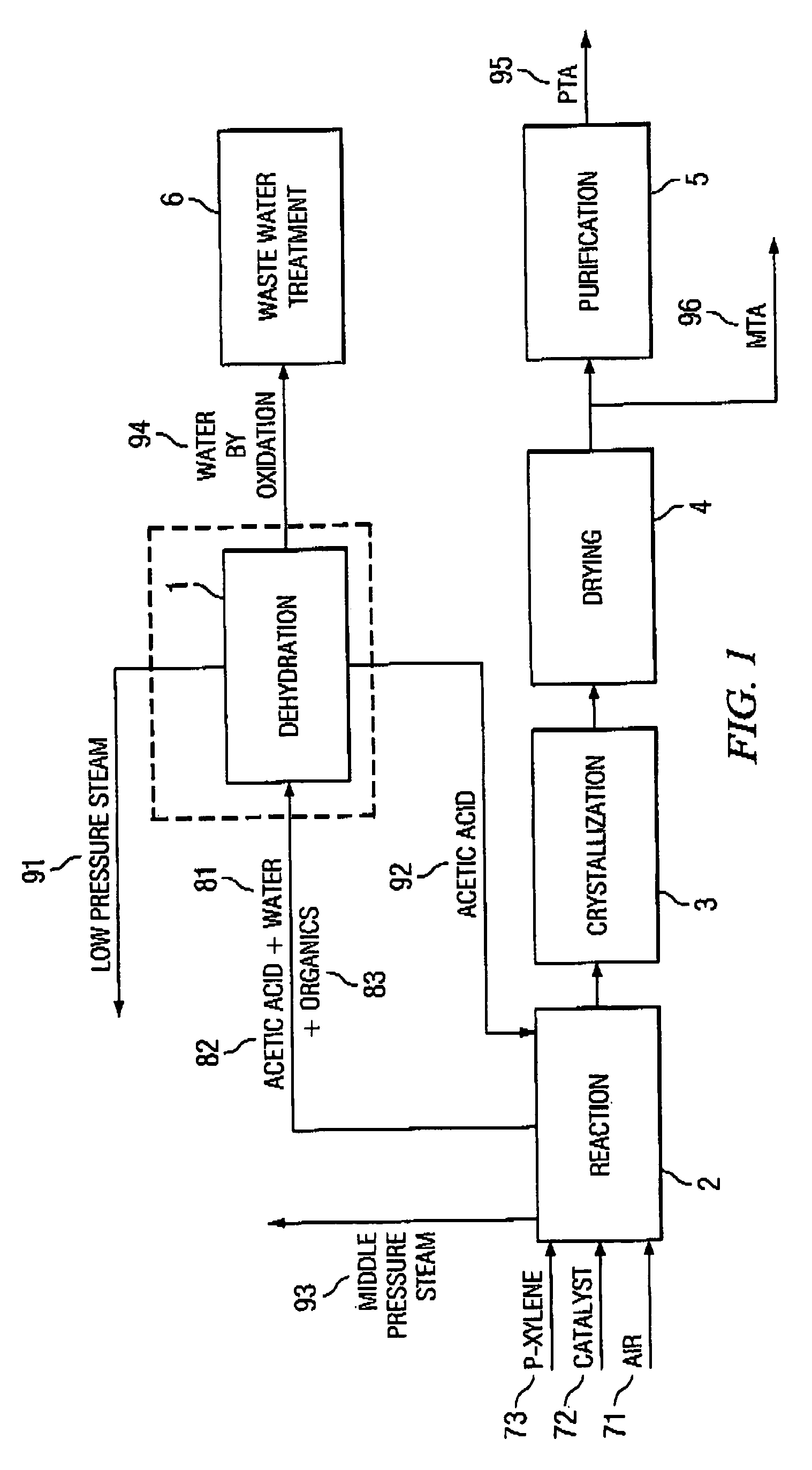

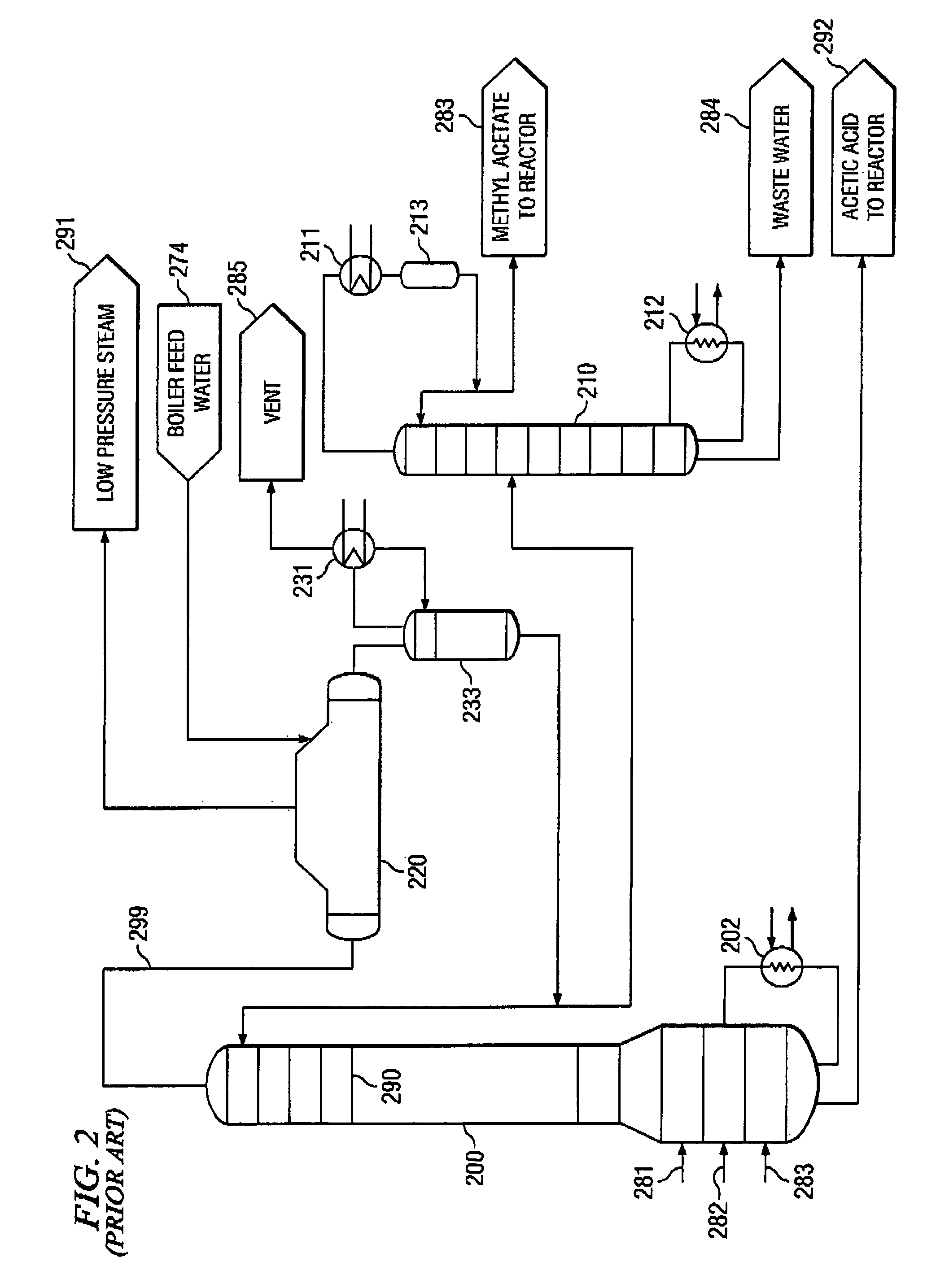

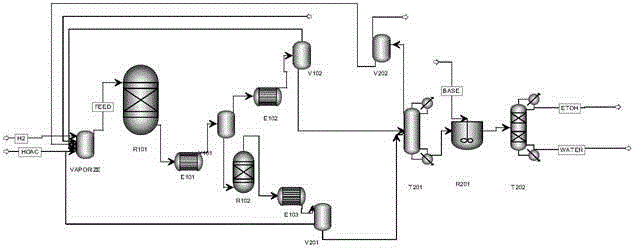

System and method for acetic acid recovery during terephthalic acid production

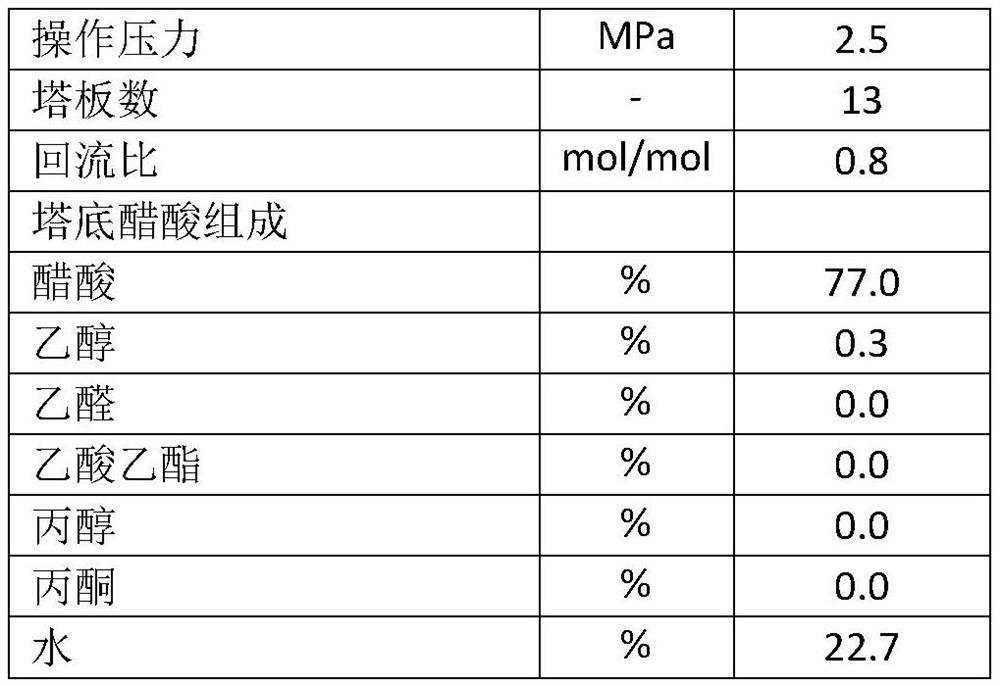

InactiveUS7048835B2Expense of additional steam consumptionRestore energyOrganic compound preparationDistillation regulation/controlAcetic acidWater flow

A distillation system and method for recovering acetic acid from a feed stream containing acetic acid and water stream generated during terephthalic acid production. The invention includes a dehydration column utilizing azeotropic distillation to recover the acetic acid in conjunction with a condenser system to recover the energy.

Owner:AMT INT INC

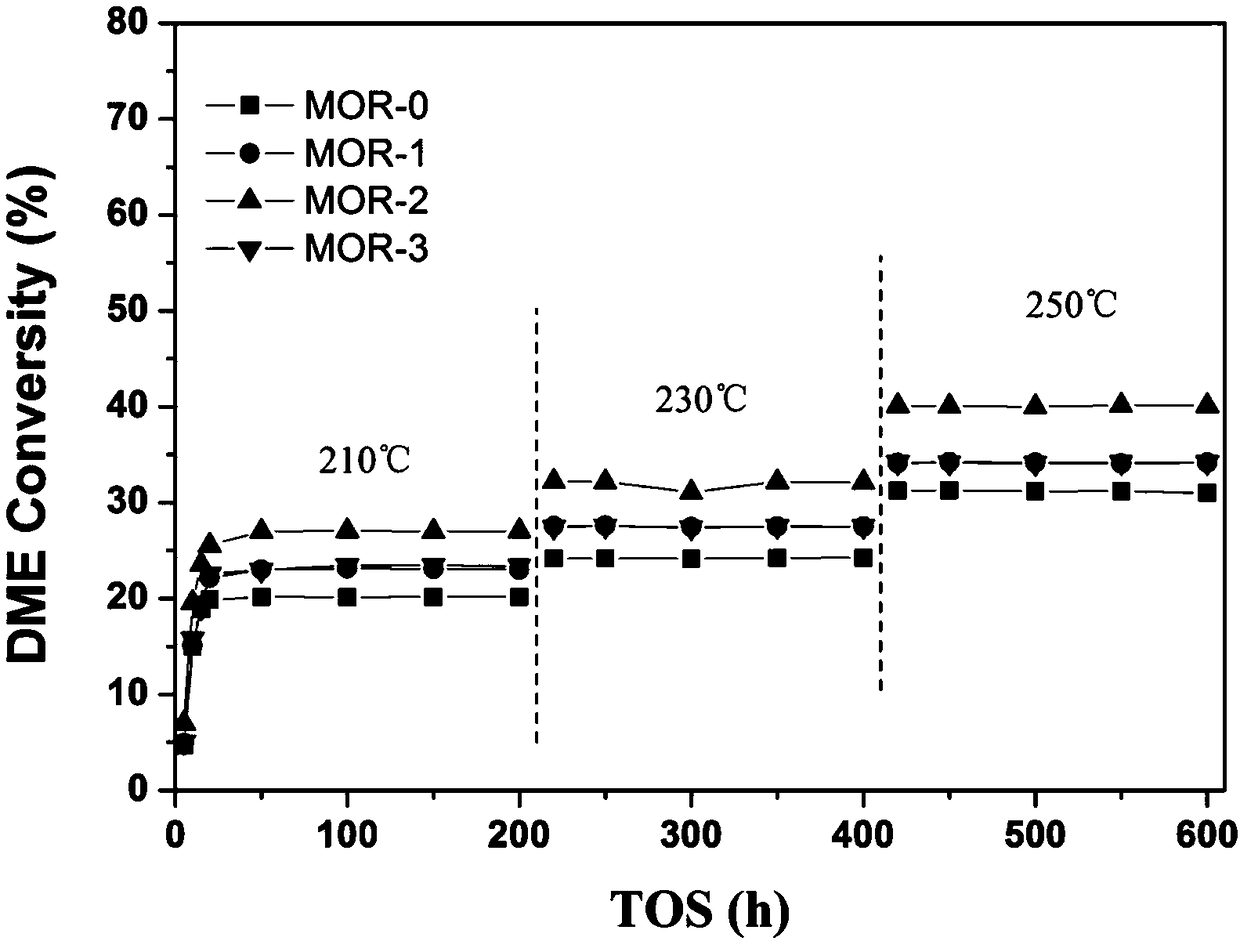

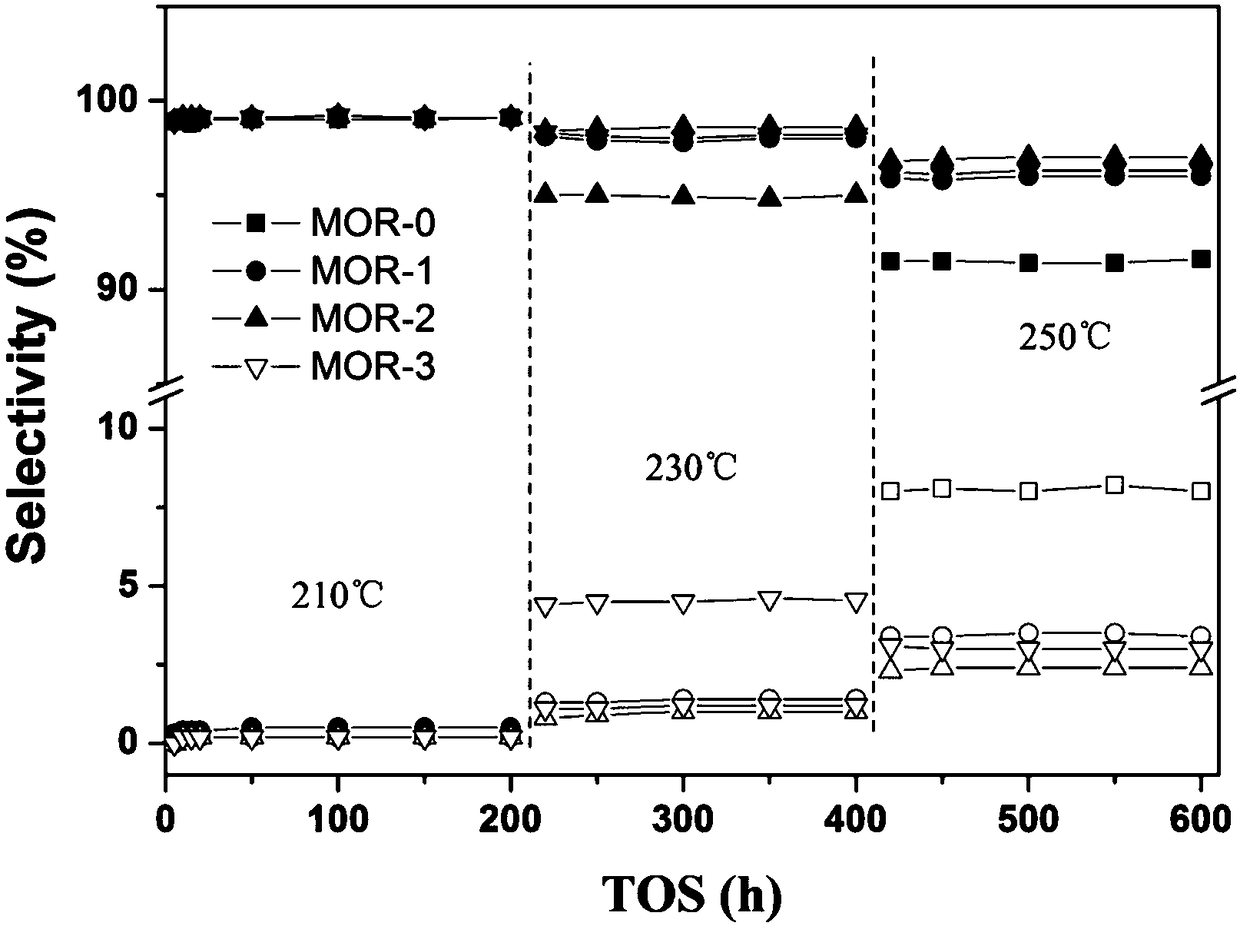

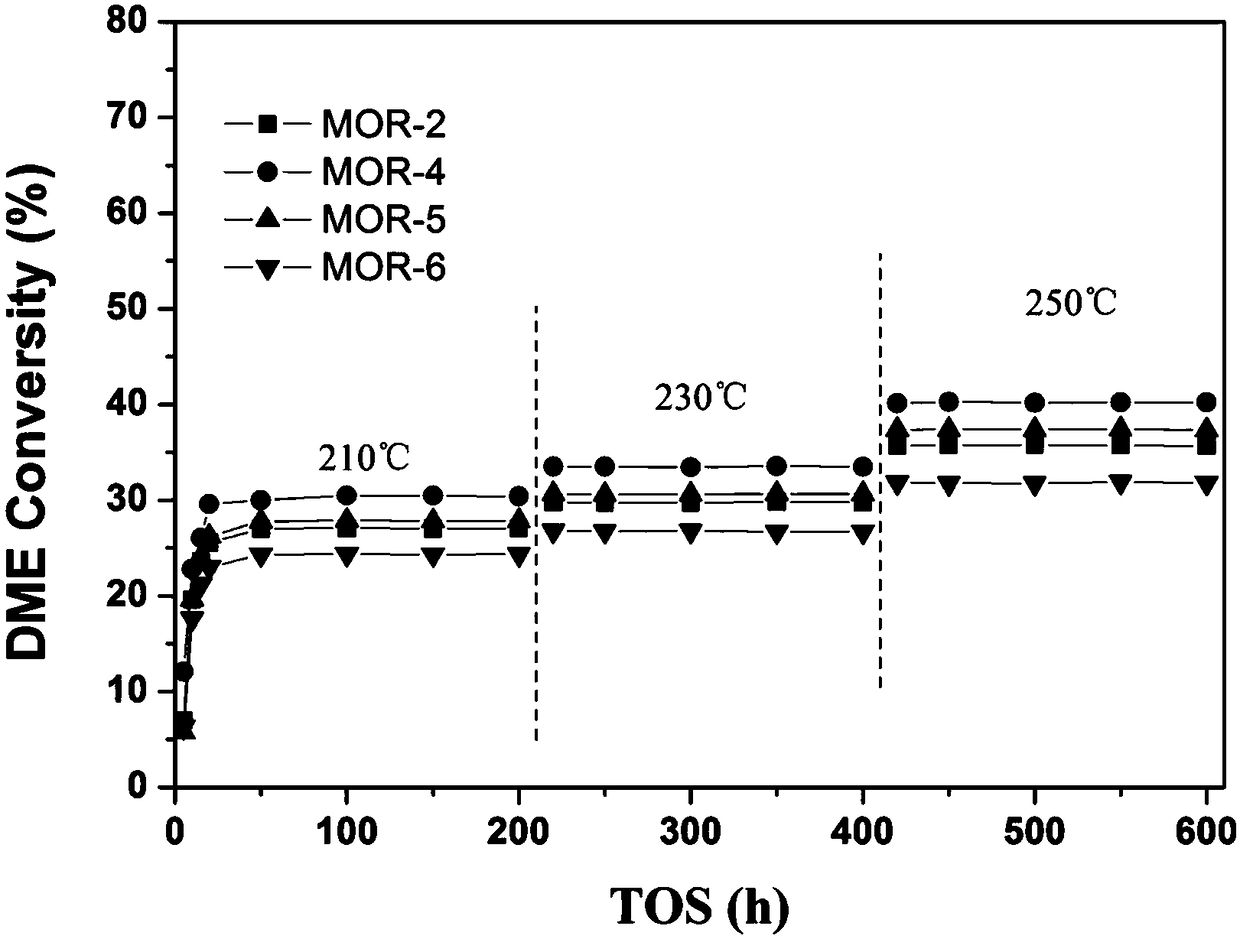

Methyl acetate molecular sieve catalyst prepared by carbonylation of dimethyl ether, modification method and application

InactiveCN108160100AEfficient modificationSimple methodMolecular sieve catalystsPreparation by carbon monoxide or formate reactionMolecular sieveChemical reaction

The invention discloses a modification method for a methyl acetate molecular sieve catalyst prepared by carbonylation of dimethyl ether, and solves the problem that in the prior art, the catalyst activity and the selectivity are reduced with the increase of the reaction temperature. The modification method provided by the invention comprises the following steps: firstly, carrying out a reaction onnon-metal modified substances with B acid sites on a 12-membered ring pore channel of a catalyst and selectively modifying the 12-membered ring pore channel, then modifying an 8-membered ring pore channel of the catalyst by adopting a metal modified substance, and carrying out ion exchange on the metal ions of the metal modifying substance and the H+ on the 8-membered ring pore channel to preparethe modified molecular sieve catalyst. The invention also discloses the methyl acetate molecular sieve catalyst prepared by carbonylation of dimethyl ether and an application of the methyl acetate molecular sieve catalyst. The preparation method provided by the invention is simple, the operation is simple and convenient, the methyl acetate molecular sieve catalyst prepared by carbonylation of dimethyl ether can be effectively modified, and high catalytic activity and high selectivity of the catalyst can be maintained at a higher reaction temperature.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

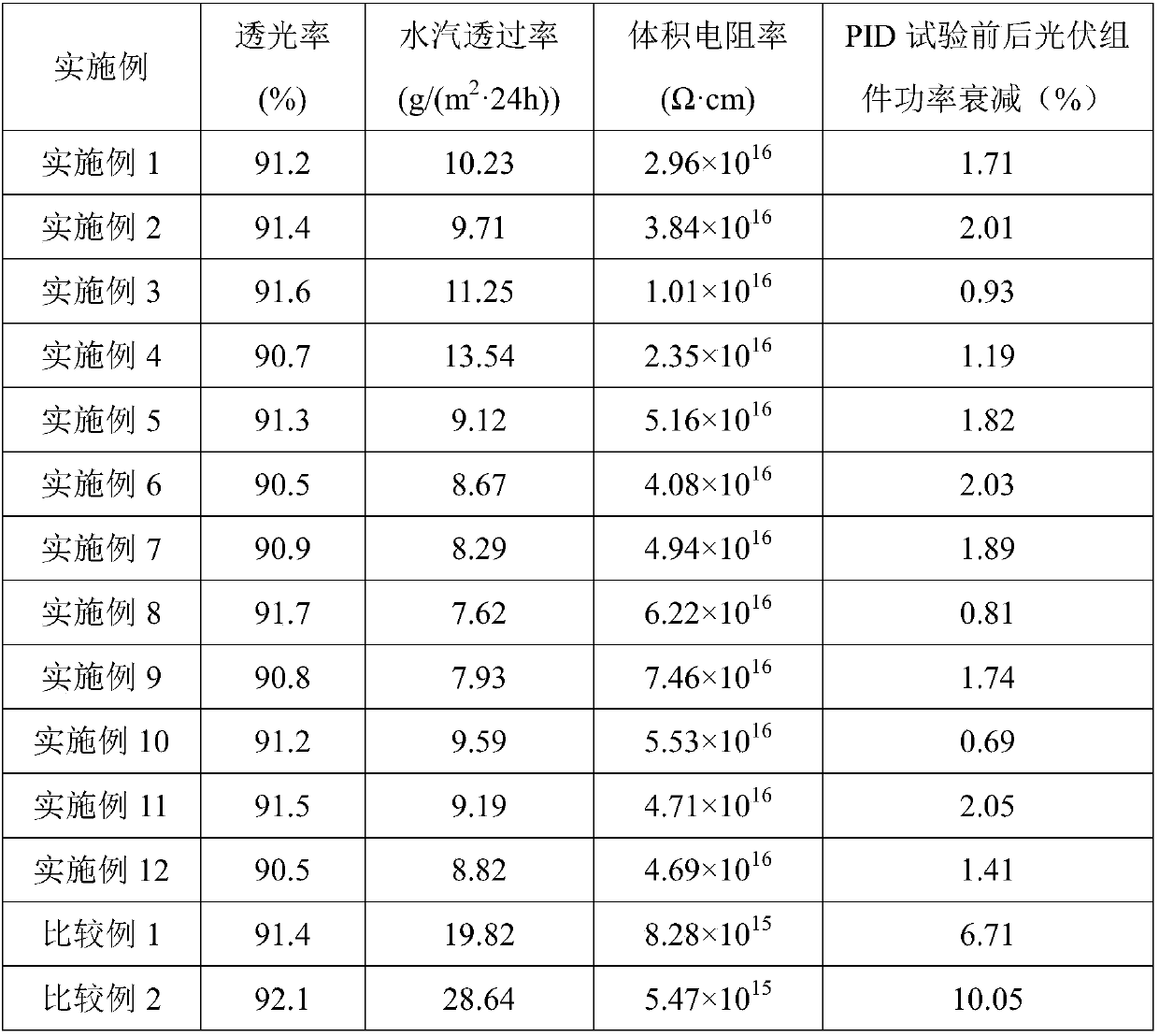

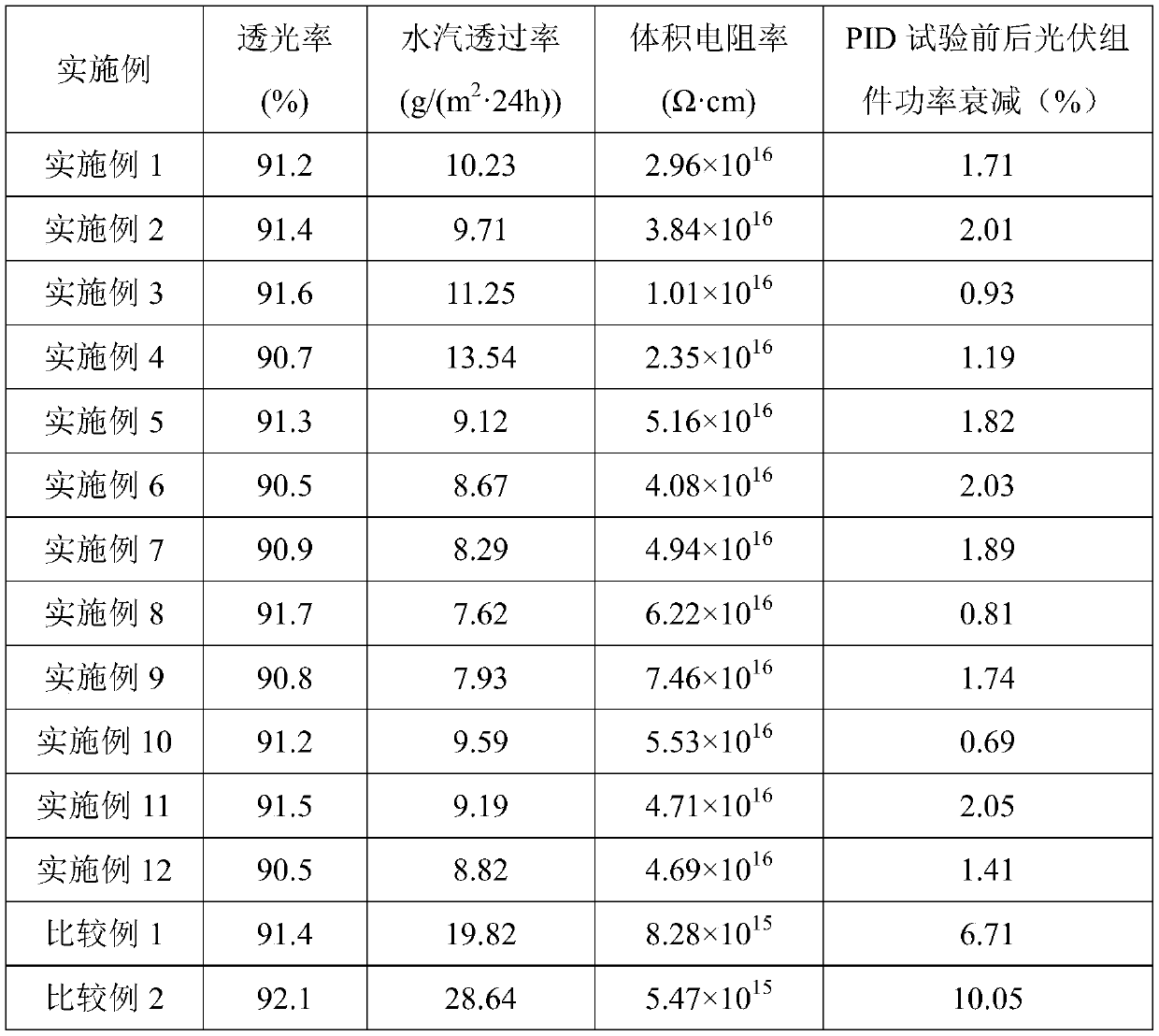

Photovoltaic encapsulation material EVA adhesive film resisting potential induced attenuation

ActiveCN108034372AImprove anti-PID performanceHigh volume resistivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesLow-density polyethyleneWater vapor

The invention discloses a photovoltaic encapsulation material EVA adhesive film resisting potential induced attenuation. EVA with the VA content being 8 to 21wt percent and low-density polyethylene orvinyl copolymer with the melting rang being 70 to 130 DEG C are mixed into matrix resin; then the matrix resin, complex absorbing sodium ion and other assistants are subjected to premixing, melt extrusion, casting and film formation, cooling, slitting and rolling processes, so that the adhesive film is formed. The ion mobility is reduced through proper reducing of the VA content, the improvementof the volume resistivity of the EVA adhesive film and the reducing of the content of acetic acid in a photovoltaic system from the source. The volume resistivity of the EVA adhesive film is improvedthrough the adding of the high-melting polyethylene or vinyl copolymer, and meanwhile water vapor transmittance is reduced. Environment of sodium ion on the surface of a battery is reduced through theadding of the complex absorbing sodium ion, passivation phenomenon caused in a battery piece antireflection layer is weakened or even eliminated, and the potential induced attenuation resistance of the adhesive film is improved.

Owner:福斯特(滁州)新材料有限公司

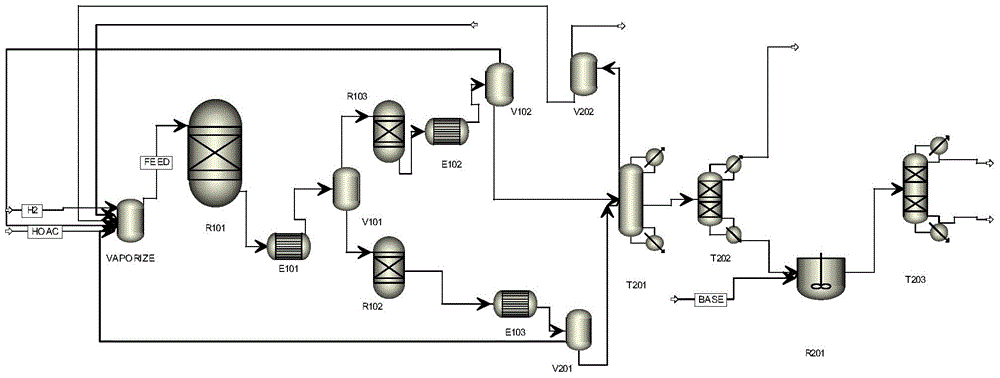

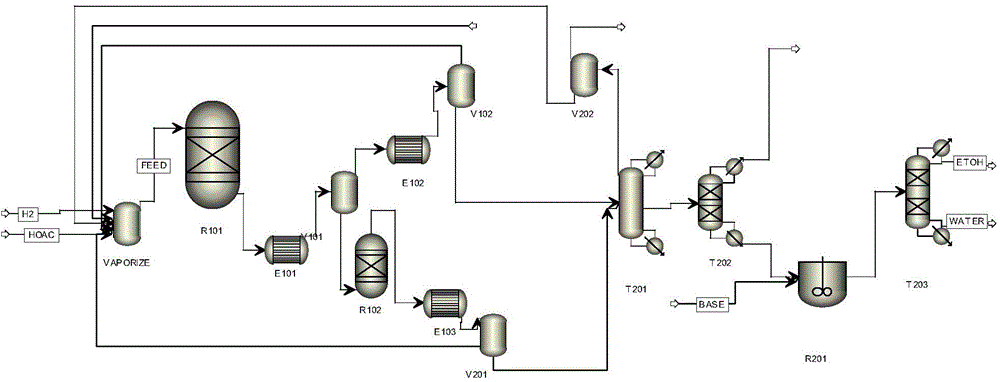

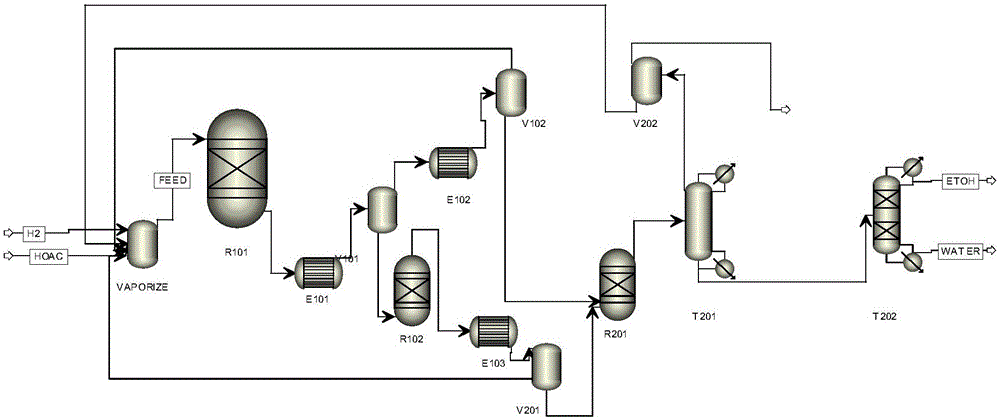

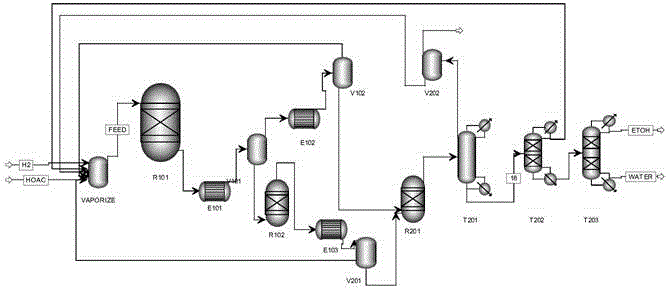

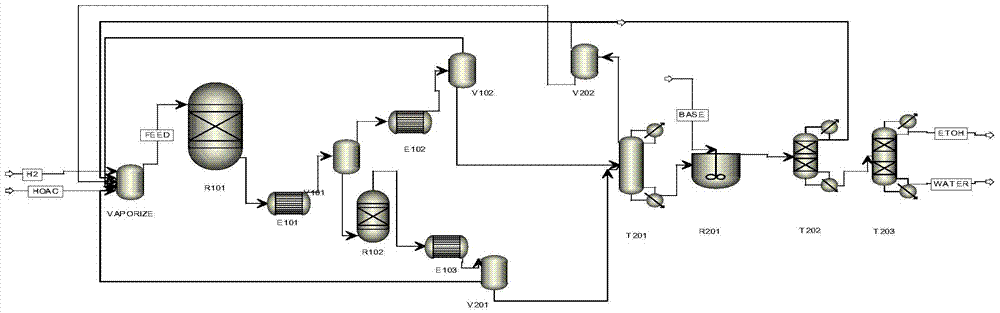

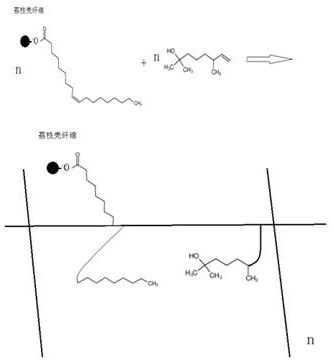

Ethanol preparation method

InactiveCN105566063AReduce acetic acid contentImprove qualityOrganic compound preparationHydroxy compound preparationSolventChemistry

The invention provides a low-energy consumption method for preparation of ethanol by acetic acid hydrogenation. The method includes the steps of: (1) first stage gas phase hydrogenation; (2) gas-liquid separation and second stage hydrogenation; (3) esterification reaction; and (4) product refining: sending a liquid phase product B to a first rectification tower, sending first tower bottom fraction to a second rectification tower, returning part of the second tower top fraction into a hydrogenation reactor of (1), and recovering part of the second tower top fraction as a mixed solvent product, sending second tower bottom fraction into a neutralization reactor, adding an alkaline substance to carry out neutralization reaction; and sending the neutralized second tower bottom fraction to a third rectification tower. The method can reduce energy consumption and improve the quality of ethanol product.

Owner:CHINA PETROLEUM & CHEM CORP +3

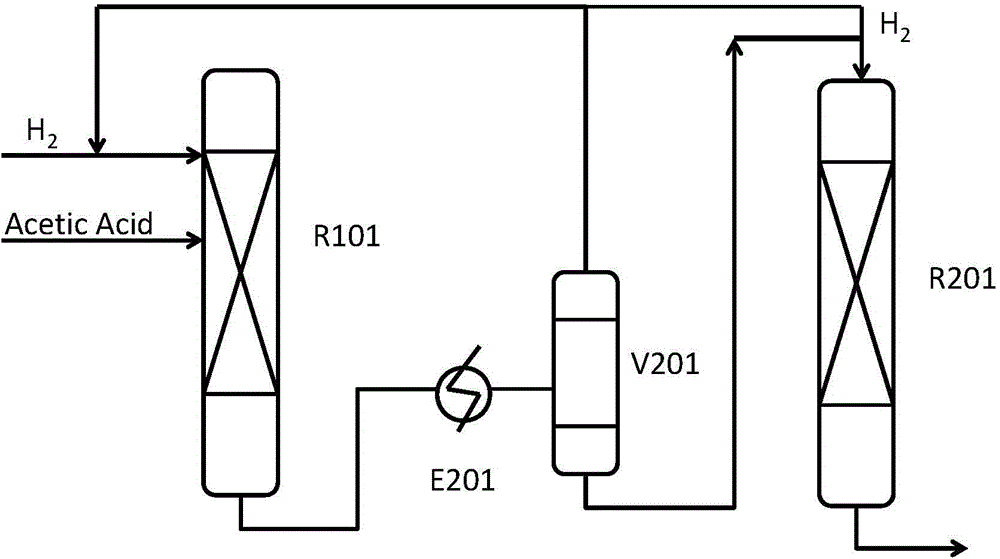

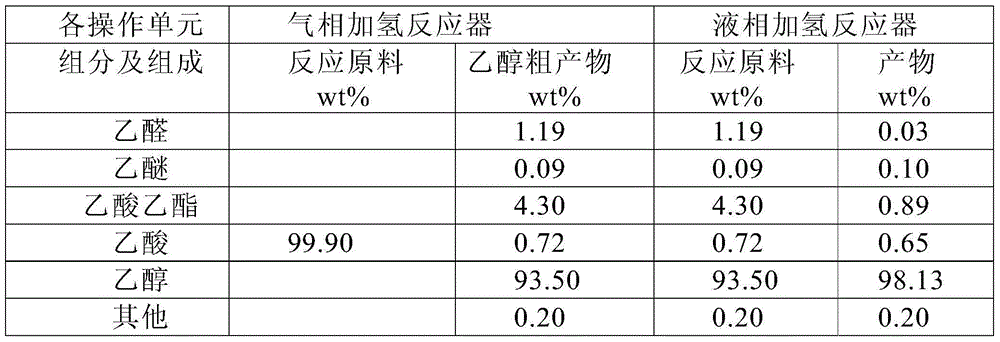

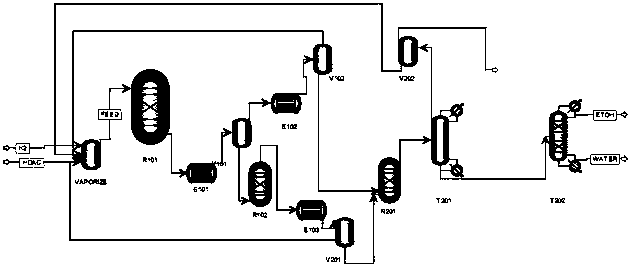

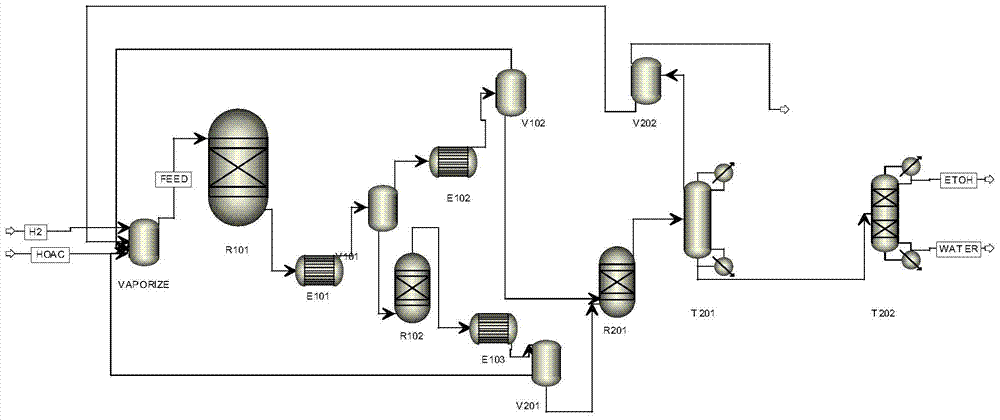

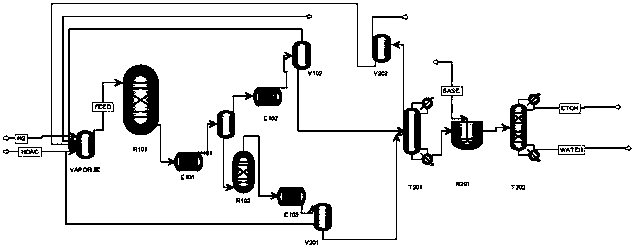

Method for preparing high-quality ethanol through hydrogenating acetic acid

ActiveCN104557454AReduce acetic acid contentImprove qualityOrganic compound preparationCarboxylic acid esters preparationAcetic acidHydrogen

The invention discloses a method for preparing ethanol through hydrogenating acetic acid. The method comprises the steps of directly carrying out gas phase hydrogenation on acetic acid so as to prepare a crude ethanol product, separating a liquid phase by a gas-liquid separation tank, and then, carrying out liquid phase hydrogenation, thereby obtaining high-selectivity ethanol. The method has the advantages that the quality of the final ethanol product can be improved, and the energy consumption of a subsequent separation process can be effectively lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparation of ethanol by acetic acid hydrogenation

ActiveCN105566064AReduce acetic acid contentImprove qualityOrganic compound preparationHydroxy compound separation/purificationSolventChemistry

The invention provides a low-energy consumption method for preparation of ethanol by acetic acid hydrogenation. The method comprises the steps of: (1) gas phase hydrogenation; (2) gas-liquid separation; (3) esterification reaction; and (4) product refining: sending a liquid phase product B to a first rectification tower, sending first tower bottom fraction to a second rectification tower, returning part of second overhead fraction into a hydrogenation reactor involved in (1), and recovering part of the second overhead fraction as a mixed type solvent product, sending second tower bottom fraction into a neutralization reactor, adding an alkaline substance to carry out neutralization reaction; and sending the neutralized second tower bottom fraction into a third rectification tower. The method can lower energy consumption and improve the quality of ethanol products.

Owner:CHINA PETROLEUM & CHEM CORP +3

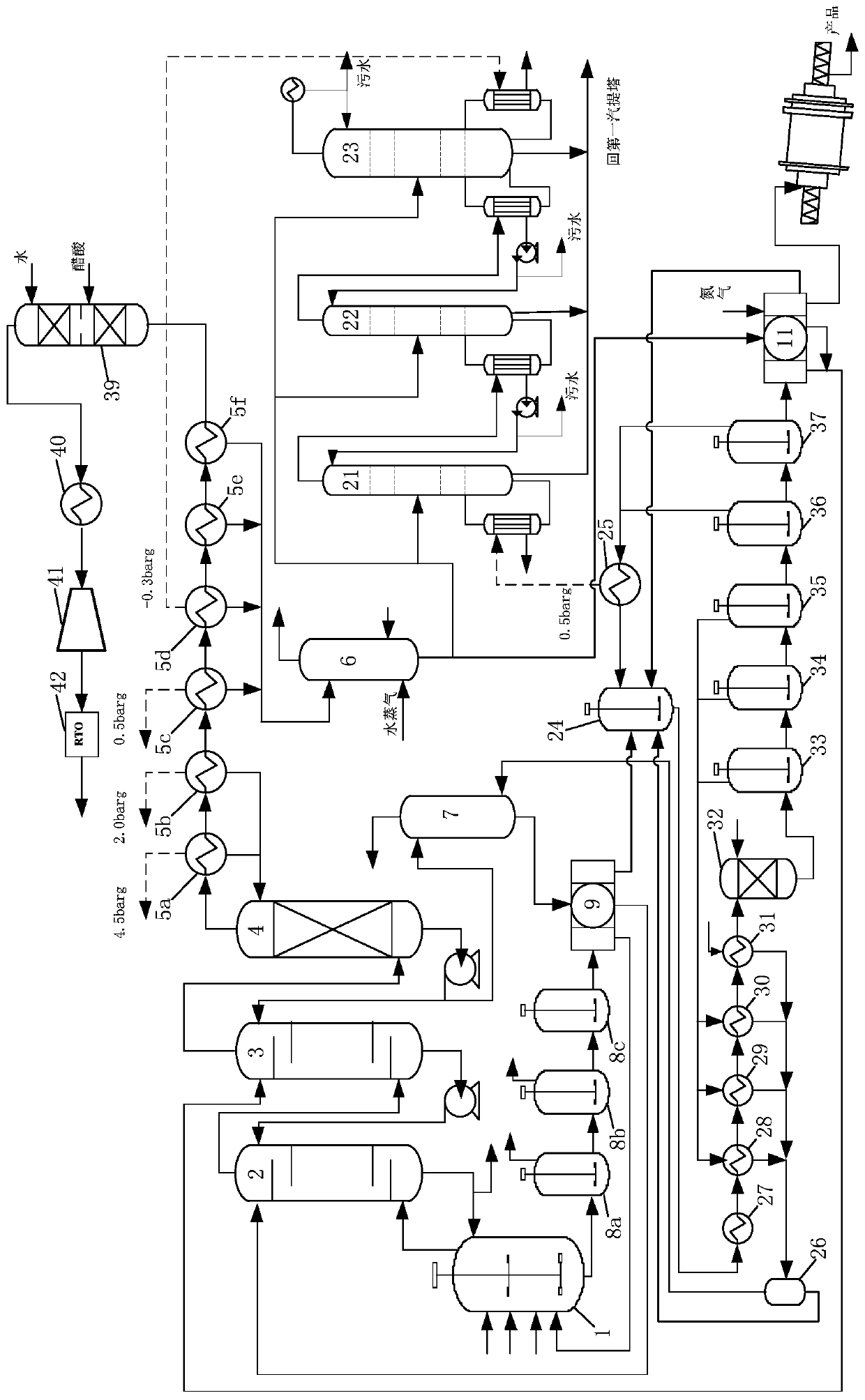

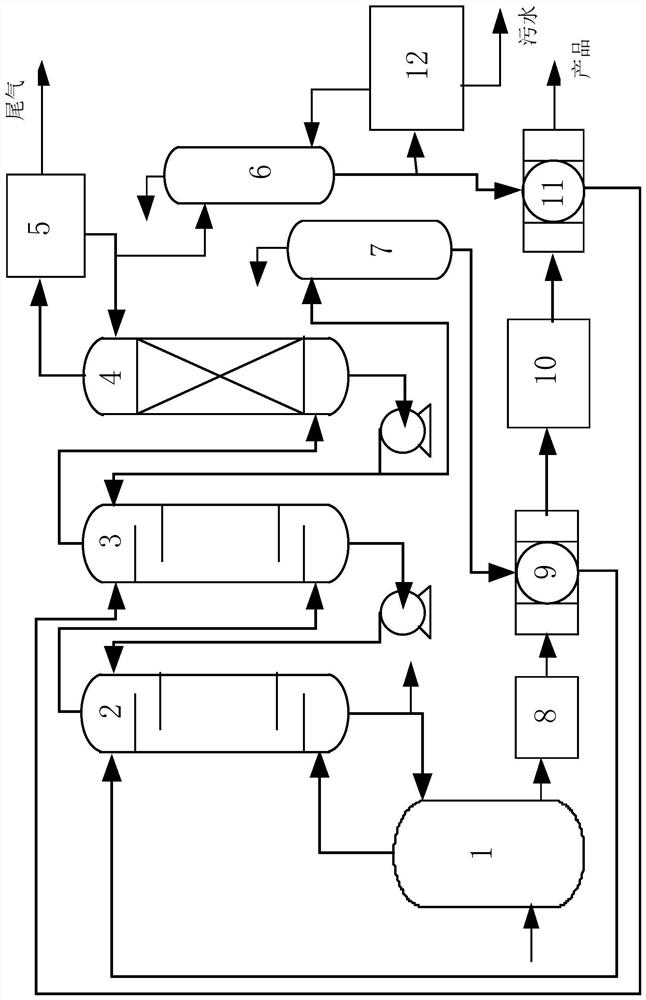

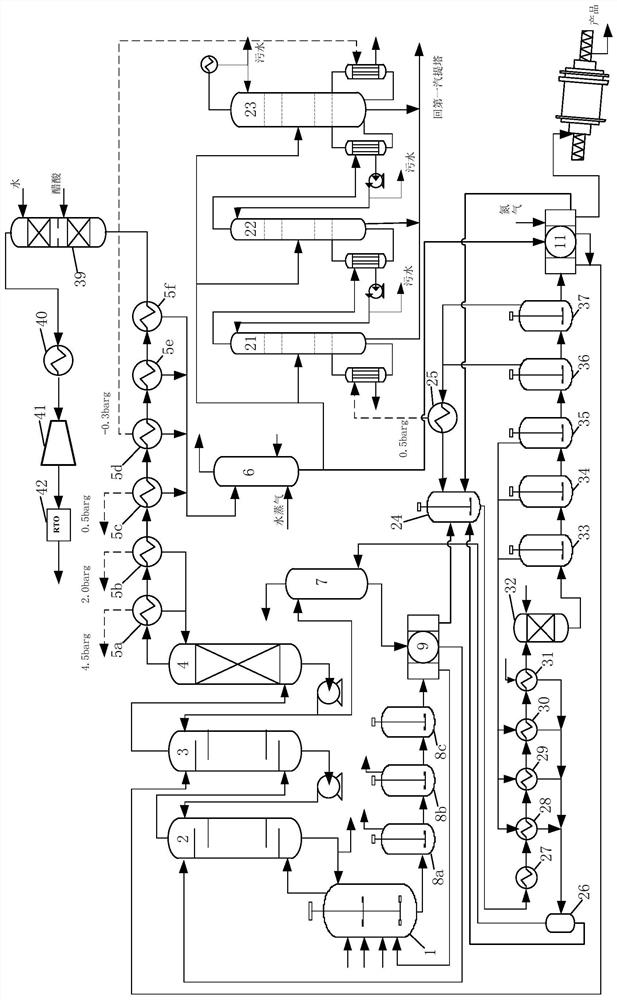

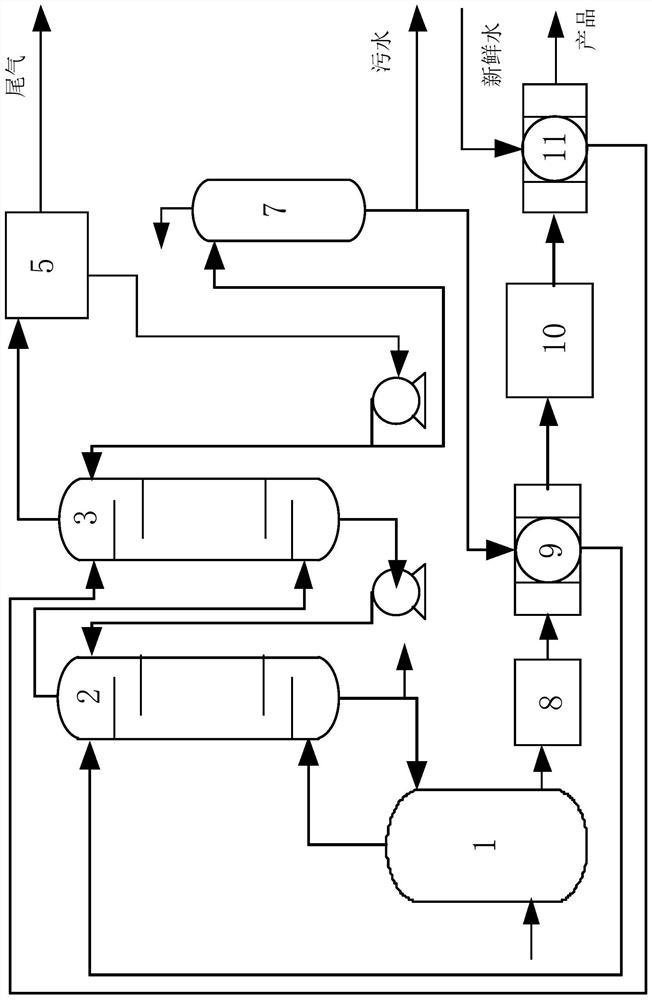

Water-rich solvent classification utilization emission reduction system for preparing terephthalic acid

ActiveCN110078284AReduce energy consumptionEffectively regulate moisture contentSpecific water treatment objectivesChemical industryDistillationFiltration

The invention discloses a water-rich solvent classification utilization emission reduction system for preparing terephthalic acid, which comprises a plurality of units, such as oxidation reaction, rectification dehydration, oxidation and purification filtration, solvent stripping, multi-effect distillation and the like. According to the system, through the optimized configuration of materials, water-rich solvents with different levels of acetic acid concentration are classified and utilized, and on the premise of ensuring product quality and effectively utilizing the reaction heat, the use amount of fresh water is greatly reduced and the organic matter content in a discharged liquid is reduced. The key technology lies in that: (1) a dehydration unit is provided with a three-stage rectifying column, the water-rich solvent produced by each unit in the oxidation and refining process is re-circulated to the rectifying columns according to a concentration matching rule, and the water-rich solvents obtained by rectification are respectively used for oxidation filter washing, refining filter washing, exhaust gas spraying and the like as required by different acetic acid concentrations; (2) self-produced low-pressure steam of the system is utilized for multi-effect distillation of the discharged liquid, thereby fully recovering acetic acid in the discharged liquid, and reducing systemacetic acid consumption.

Owner:杭州多向流化学科技有限公司 +1

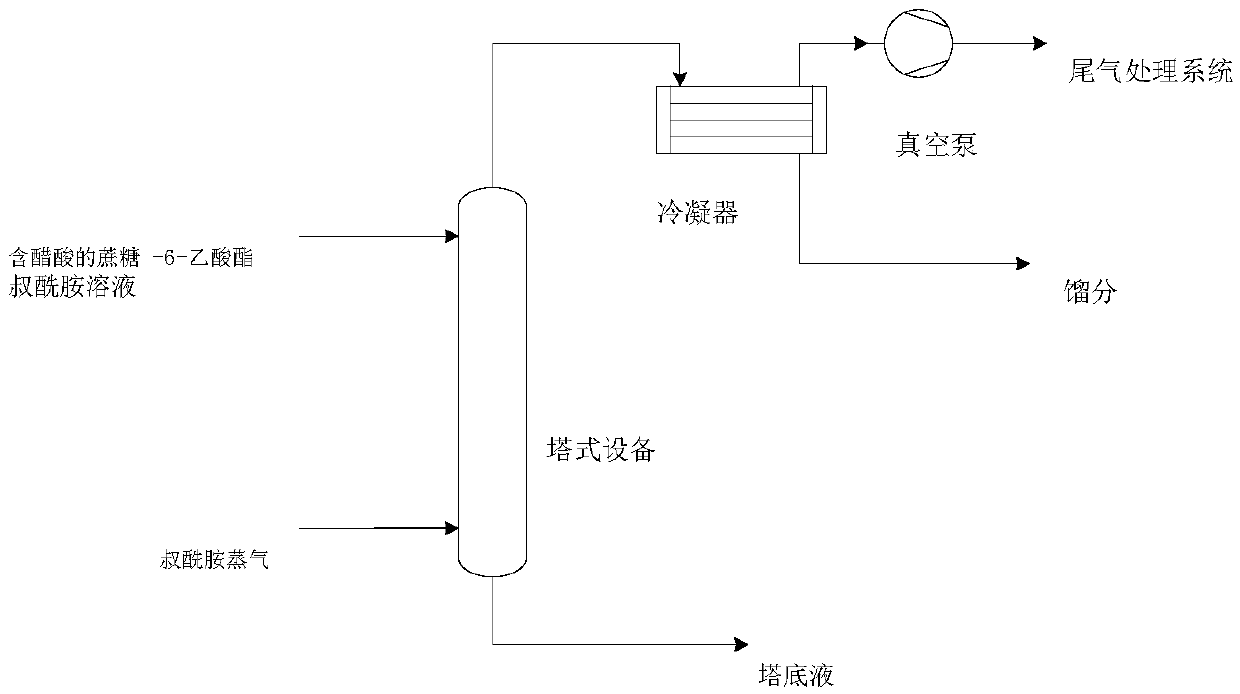

Method for removing acetic acid in sucrose-6-acetate solution and application thereof

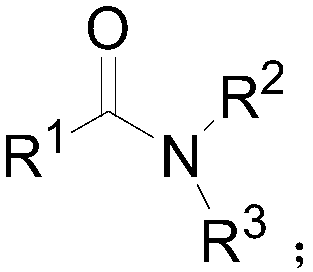

ActiveCN108676041AWon't clogFree from destructionEsterified saccharide compoundsSugar derivativesAcetic acidResidence time

The invention discloses a method for removing acetic acid in a sucrose-6-acetate solution and application thereof. The method comprises the following steps: under a certain residence time condition, in tower equipment for removing acetic acid, vapor formed by tertiary amide of certain temperature is in contact with the sucrose-6-acetate solution containing acetic acid in a continuous countercurrent manner, thereby achieving the purpose of removing the acetic acid from the sucrose-6-acetate solution. The method provided by the invention can be applied to the synthesis of sucrose-6-acetate and sucralose, has the advantages of simple process, high acetic acid removal rate, no damage to a sucrose-6-acetate product, continuity and the like, and is very suitable for industrial production.

Owner:SHANDONG NHU FINE CHEM SCI & TECH CO LTD +1

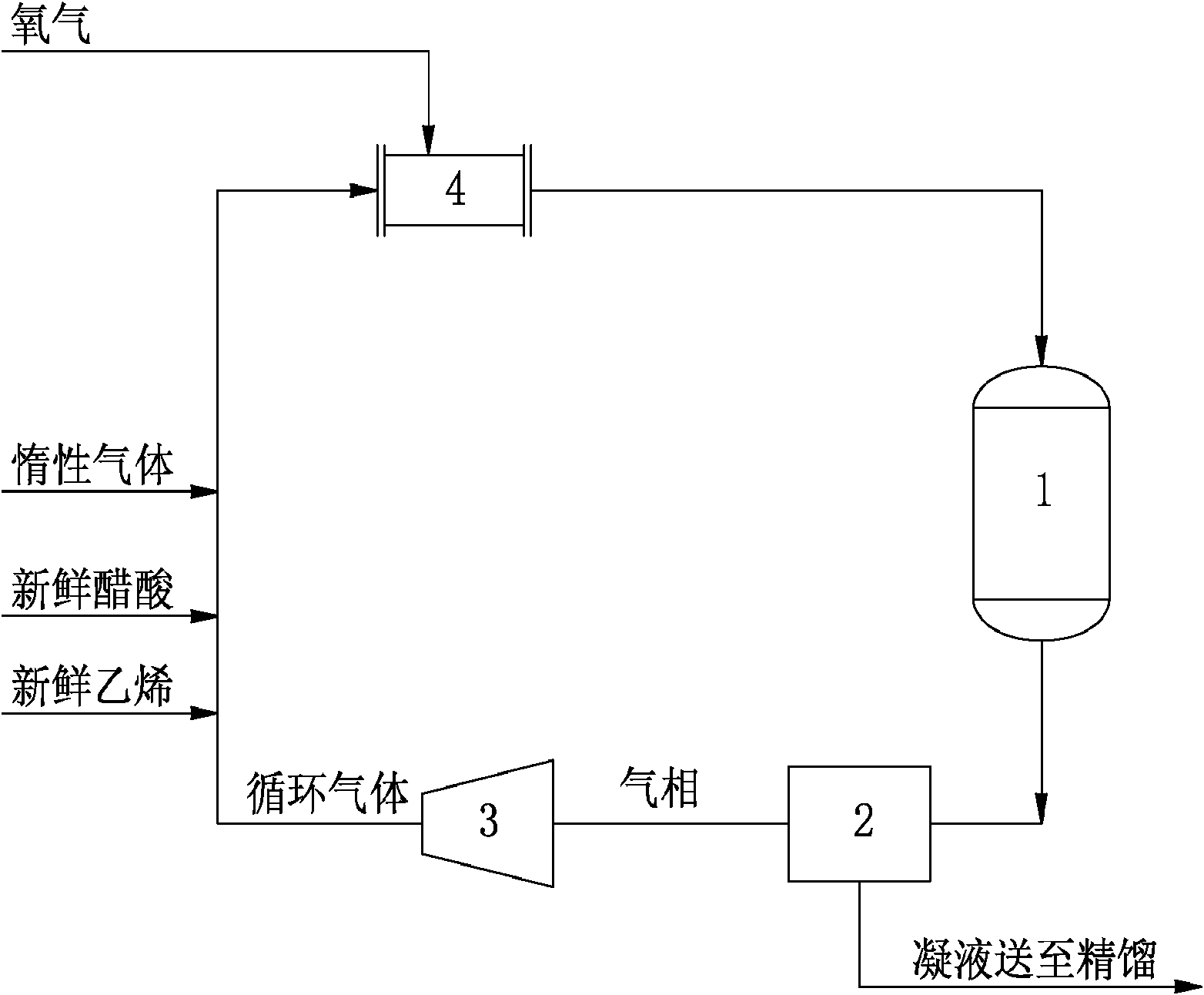

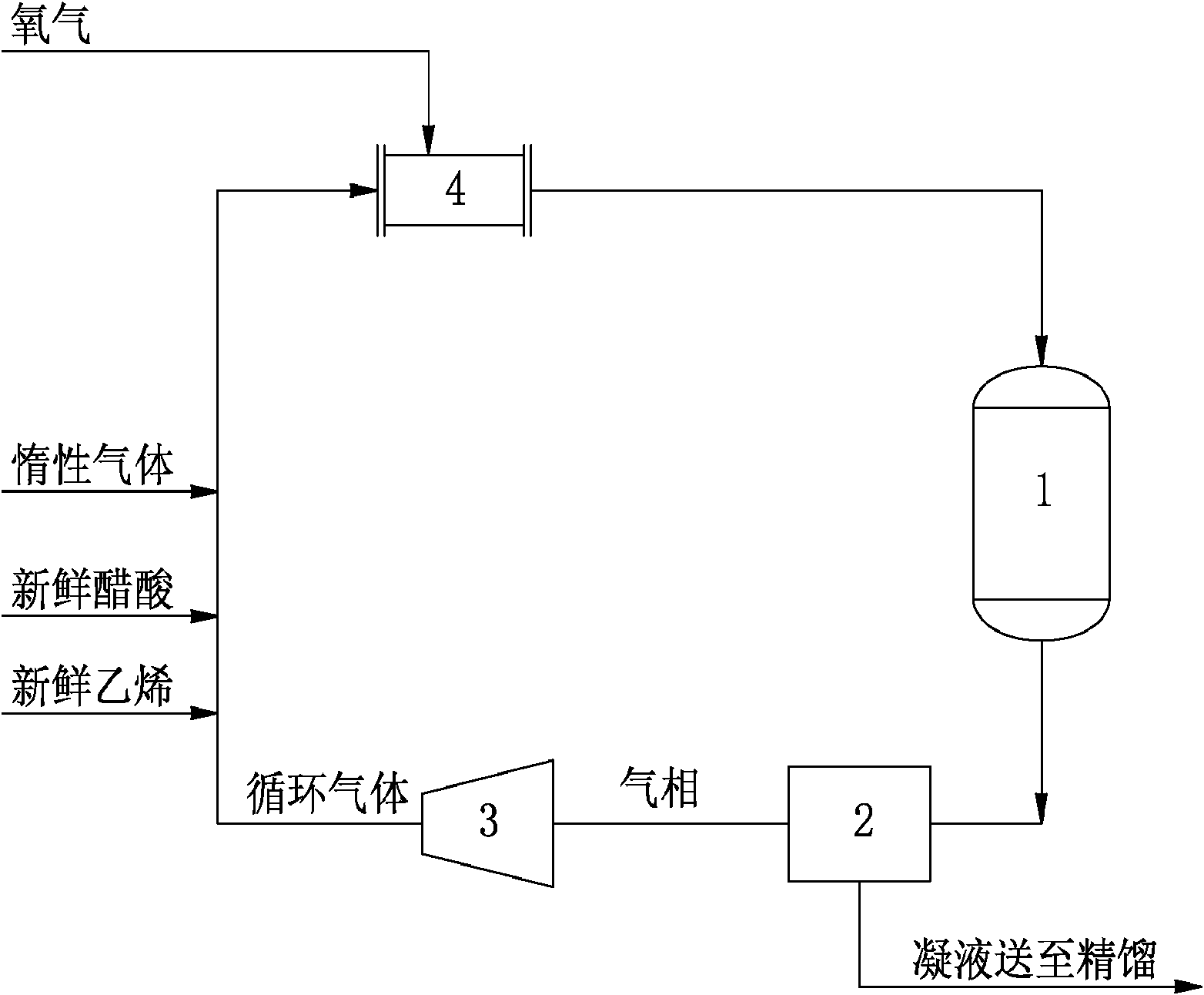

Method for producing vinyl acetate

InactiveCN102381966ARaise the explosive limitIncrease concentrationOrganic compound preparationCarboxylic acid esters preparationNitrogenReaction temperature

The invention discloses a method for producing vinyl acetate. Inert gas is added into recycle gas to improve the explosion limit of oxygen, enlarge a stable area of a reaction system and improve the oxygen concentration of the reaction system, so that the reaction temperature is reduced, the service life of a catalyst is prolonged, and the selectivity of the vinyl acetate is improved. The inert gas is nitrogen or a mixture of nitrogen and methane. The concentration of the inert gas at the inlet of a reactor is 8 to 30 mol percent, and the molar concentration of the oxygen at the inlet of the reactor is 10.5 to 12 mol percent.

Owner:TIANJIN UNIV

Method for production of ethanol by acetic acid hydrogenation

ActiveCN105566057AReduce acetic acid contentImprove qualityOrganic compound preparationHydroxy compound preparationAcetic acidGas phase

The invention provides a low-energy consumption method for production of ethanol by acetic acid hydrogenation. The method comprises the steps of: (1) gas phase hydrogenation; (2) gas-liquid separation; (3) esterification reaction; and (4) product refining: sending a liquid phase product B to a neutralization reactor, adding an alkaline substance to carry out neutralization reaction, bringing the neutralization product into a first rectification tower so as to obtain first overhead fraction containing acetaldehyde, ethyl acetate and acetone and first tower bottom fraction, i.e. a crude ethanol product containing ethanol and water, returning part of the first overhead fraction into a gas phase hydrogenation reactor, and sending the first tower bottom fraction to a second rectification tower so as to obtain second tower bottom fraction containing water, ethanol, butanol and acetate. The method can reduce energy consumption and improve the quality of ethanol product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethanol through acetic acid hydrogenation

ActiveCN105566060AReduce acetic acid contentImprove qualityOrganic compound preparationHydroxy compound preparationLiquid productGas phase

The invention provides a low-energy consumption method for preparing ethanol through acetic acid hydrogenation. The method comprises 1, gas phase hydrogenation, 2, gas-liquid separation, 3, esterification reaction and 4, product refining: feeding a liquid product B into a first rectifying tower, feeding a part of the first rectifying tower top fraction containing acetaldehyde, ethyl acetate and acetone back to a gas phase hydrogenation reactor, feeding the first rectifying tower bottom fraction as a crude ethanol product containing ethanol, ethyl acetate and water into a neutralization reactor, adding an alkaline substance into the neutralization reactor, carrying out a neutralization reaction process, feeding the neutralized first rectifying tower bottom fraction into a second rectifying tower, and carrying out separation to obtain a second rectifying tower top fraction containing ethanol and water and a second rectifying tower top fraction containing water, butanol and acetate, wherein the second rectifying tower top fraction has ethanol content of 85-95wt% and an acidity value of 0-25mg / L. The method can reduce energy consumption and improve ethanol product quality.

Owner:CHINA PETROLEUM & CHEM CORP +3

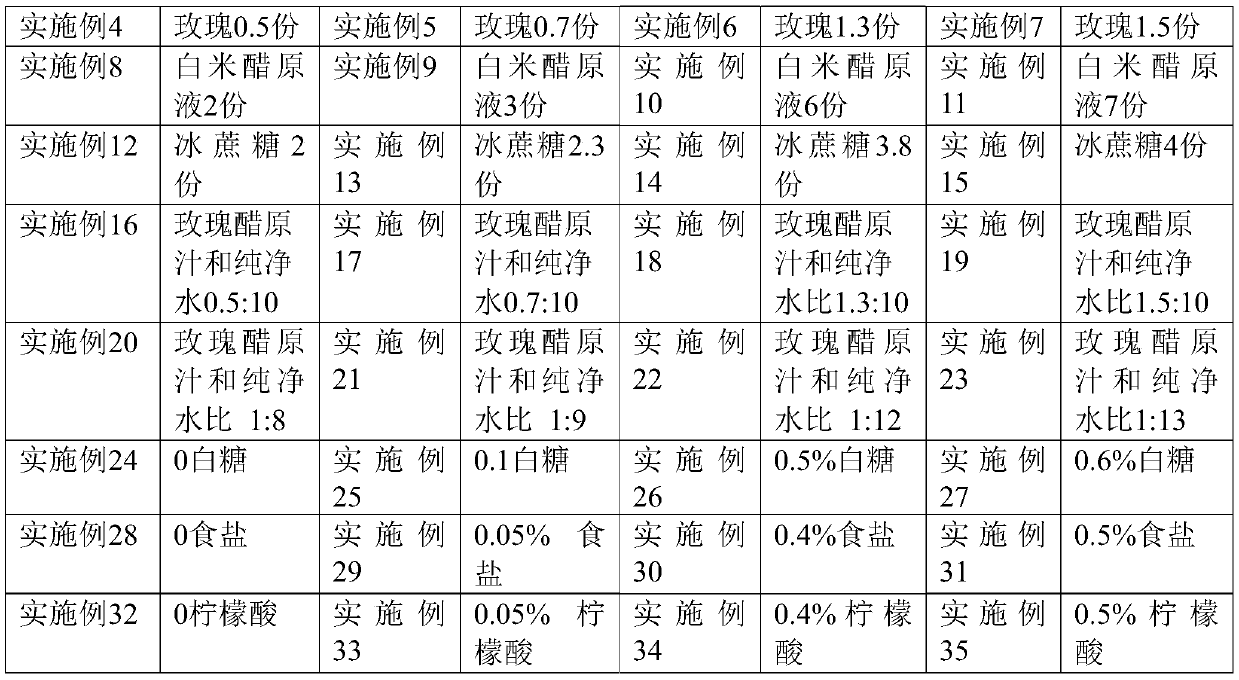

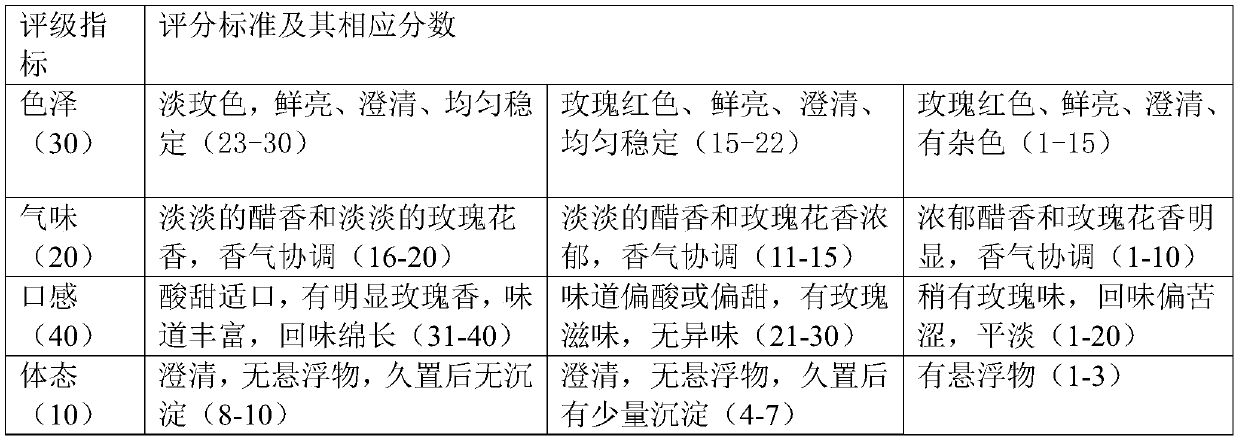

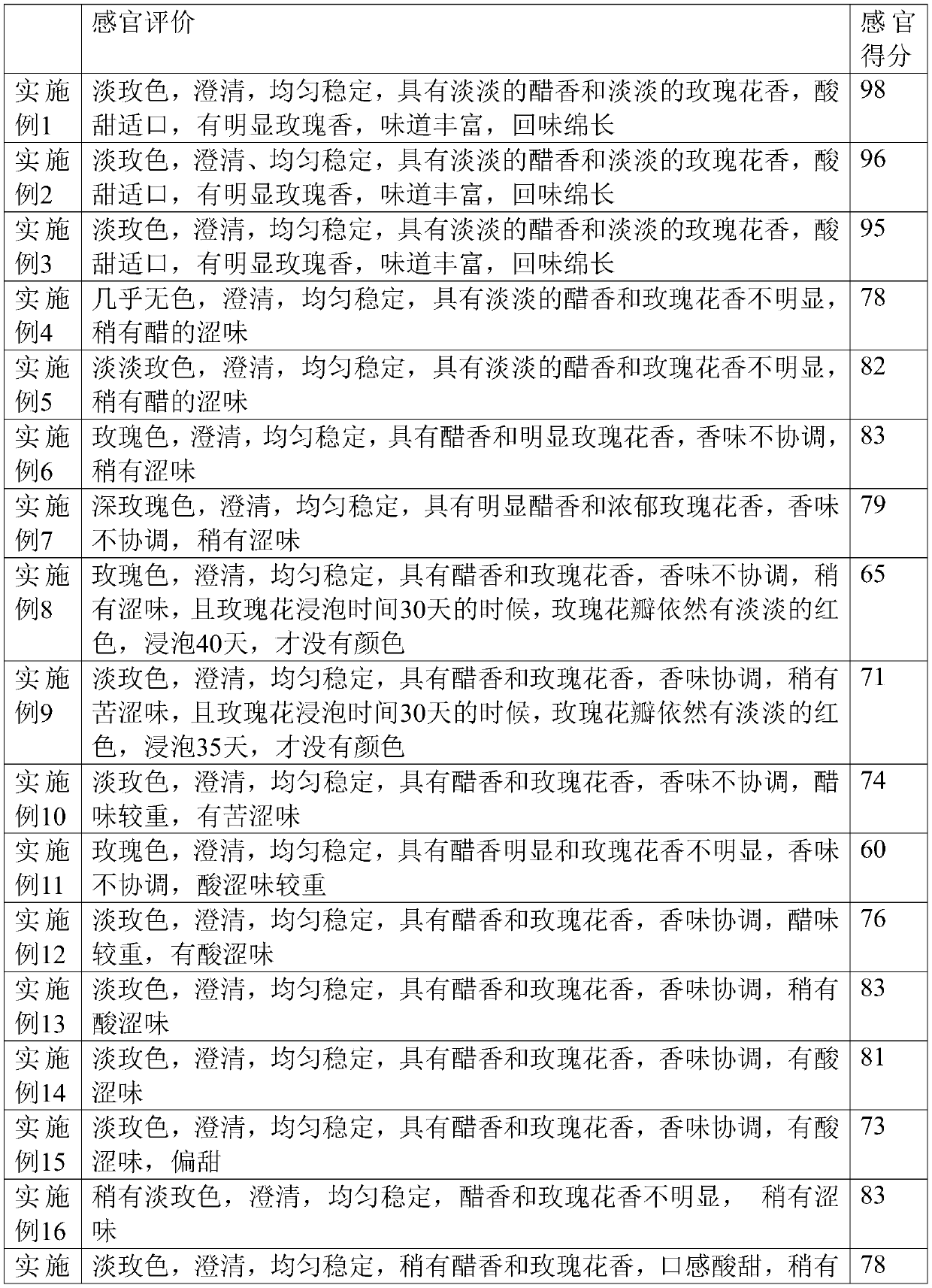

Method for producing rose vinegar drink

PendingCN110338323AImprove sour tasteBalance of sourness and astringencyFood preservationVinegar preparationHigh concentrationPetal

The invention relates to a method for producing a rose vinegar drink. The method comprises the following steps that (1) flower bases and flower pistils of picked fresh organic edible roses are removed, and only petals are reserved for standby application; (2) a superior white rice vinegar stock solution and polycrystal rock candy are selected, 0.8-1.1 parts of the rose petals are poured into 4-6 parts of the white rice vinegar stock solution by weight, 2.5-3.5 parts of the rock candy is added by weight, and after seeping, brewing and soaking are performed for 20-25 days, all nutrient substances of the roses are completely separated out and brewed into the vinegar; (3) after the rose petals are completely whitened, the petals are filtered out several times, rose residues are coarsely filtered, and liquid is finely filtered to prepare the high-concentration and pure raw juice of the rose vinegar drink; (4) the raw juice of the rose vinegar drink and purified water are diluted according to a weight ratio of (0.8-1.1): (9.5-11.5), after dilution is completed, 0.2-0.4% of white sugar, 0.1-0.3% of salt, 0.03-0.05% a food preservative and 0.1-0.3% of citric acid are added by weight, uniform mixing is carried out, and the rose vinegar drink is obtained. The rose vinegar drink is light rosy liquid, has light vinegar scent and rose scent, is palatably sweet and sour, has distinct rose fragrance, is rich in flavor, and has a long aftertaste.

Owner:河南浪漫步庭生态农业有限公司

Ethyl alcohol and acetic ether-containing mixed solvent

InactiveCN106187692AReduce acetic acid contentImprove qualityOrganic compound preparationCarboxylic acid esters separation/purificationAcetic acidAlcohol

The invention provides a mixed solvent product with acetic ether and ethyl alcohol which serve as main components. The solvent product contains 30 to 75 weight percent of the ethyl alcohol and 20 to 60 weight percent of the acetic ether; an acid value is 0 to 5 mg / L, which is calculated based on acetic acid, and the moisture content is 0 to 20 weight percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

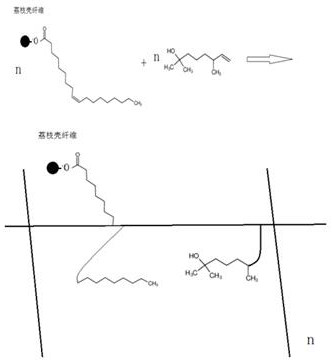

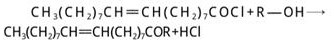

Sterilization and clarification method of aged litchi alcoholic beverage

ActiveCN111961559AIncrease the juice yieldIncrease productionImmobilised enzymesAlcoholic beverage preparationBiotechnologySucrose

The invention discloses a sterilization and clarification method of an aged litchi alcoholic beverage, and relates to the field of sterilization, purification, clarification and aging of alcoholic beverages, and the method comprises the following steps: (1) litchi treatment, (2) litchi juice sterilization treatment: adding sucrose and malic acid into litchi juice, adjusting sugar degree and pH, and adding dimethyl dicarbonate, and treating at normal temperature to obtain sterilized litchi juice; (3) litchi juice fermentation: uniformly mixing the sterilized litchi juice, saccharomycetes, citric acid, amino acids, preservatives, vitamins and absolute ethyl alcohol, and performing sealed fermentation to obtain the litchi alcoholic beverage; (4) clarifying the litchi alcoholic beverage: adding bentonite into the litchi raw wine, uniformly stirring, standing, taking supernate, and filtering to obtain clarified wine liquid; and (5) wine liquid aging process: heating the clarified wine liquid to 70 DEG C, keeping the temperature for 10 minutes, quickly cooling to-7-0 DEG C, and keeping the temperature for 5-15 days to obtain the aged litchi alcoholic beverage.

Owner:福建泉智生物科技有限公司

Method for preparing ethanol and co-producing mixed solvent through acetic acid hydrogenation

InactiveCN105566059AReduce acetic acid contentImprove qualityOrganic compound preparationCarboxylic acid esters preparationLiquid productGas phase

The invention provides a low-energy consumption method for preparing ethanol and co-producing a mixed solvent through acetic acid hydrogenation. The method comprises 1, gas phase hydrogenation, 2, gas-liquid separation, 3, esterification reaction and 4, product refining: feeding a liquid product B into a neutralization reactor, adding an alkaline substance into the reactor, carrying out a neutralization reaction process, feeding the neutralization product into a first rectifying tower, feeding a part of the first rectifying tower top fraction back to a gas phase hydrogenation reactor, feeding the first rectifying tower bottom fraction into a second rectifying tower, feeding a part of the second rectifying tower top fraction back to the gas phase hydrogenation reactor, collecting a part of the second rectifying tower top fraction as a mixed solvent, wherein the mixed solvent comprises ethanol, ethyl acetate and water according to an ethanol-ethyl acetate mass ratio of 1: 0.05-1.1, has water content of 1-15wt% and an acidity value of 0-30mg / L and the second rectifying tower bottom fraction contains water, acetate and butanol, feeding the second rectifying tower bottom fraction into a third rectifying tower, and carrying out separation to obtain a third rectifying tower bottom fraction containing water, acetate and butanol and a third rectifying tower top fraction containing ethanol and water, wherein the third rectifying tower top fraction has ethanol content of 85-95wt% and an acidity value of 0-25mg / L. The method can reduce energy consumption and improve ethanol product quality.

Owner:CHINA PETROLEUM & CHEM CORP +3

A kind of vacuum low-temperature drying method of bovine bone glue

ActiveCN107823896BReduce acetic acid contentReduce energy consumptionEvaporationAcetic acidEthylic acid

The invention discloses a vacuum low-temperature drying method for bovine bone glue, which comprises the following steps: 1) raw material preparation step: loading the concentrated bovine bone glue extract into a container, wherein the volume of the concentrated bovine bone glue extract is V1, and the container The volume is V2, V1: V2≤20%; 2) vacuum drying step: first the container of step 1) is put into microwave vacuum drying equipment and heated, so that the bovine bone glue extract concentrate is in a low-temperature boiling state; water vapor and The acetic acid vapor is sucked away by a vacuum pump, and the bovine bone glue extract is concentrated and dried to obtain the bovine bone glue. The vacuum low-temperature drying method of the invention has the characteristics of low acetic acid content, low energy consumption, short drying time, high product yield and high production efficiency.

Owner:GUANGDONG JIMIN PHARMA IND

Method for producing ethanol by hydrogenation of acetic acid

ActiveCN105566058BReduce acetic acid contentImprove qualityOrganic compound preparationHydroxy compound preparationAcetic acidFluid phase

The invention provides a method for preparing ethanol by hydrogenation of acetic acid with low energy consumption, which comprises the following steps: (1) gas phase hydrogenation; (2) gas-liquid separation; (3) esterification reaction; (4) product refining: the liquid phase Product B is sent to the first rectification column to produce the first overhead fraction and the first bottom fraction, and the first overhead fraction is partially returned to the gas phase hydrogenation reactor; the first column still fraction is sent to the neutralization reactor ; The neutralized first bottom fraction is sent to the second rectification tower, separated into the second overhead fraction and the second bottom fraction, and the second overhead fraction is partly returned to the gas phase hydrogenation reactor In the process, part of it is recovered as a mixed solvent product; the second bottom fraction is sent to the third rectification column, and is separated into the third column bottom fraction containing water, acetate and butanol and the third column containing ethanol and water The top fraction, the ethanol content in the top fraction is 85-95wt%, and the acidity value is 0-25mg / L. The method can reduce energy consumption and improve the quality of ethanol products.

Owner:CHINA PETROLEUM & CHEM CORP +3

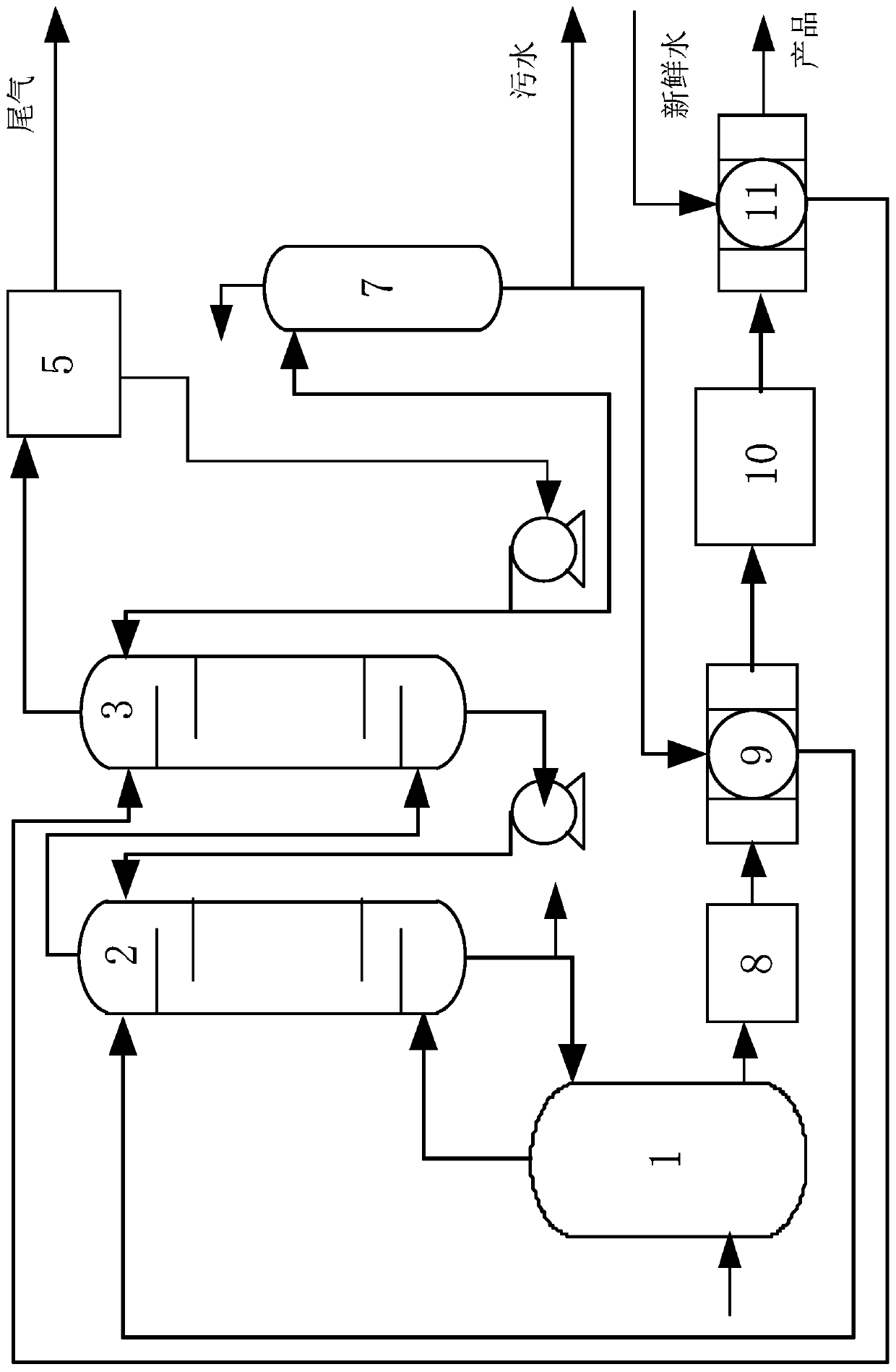

Apparatus and method for recovery of rectification residue effective components and comprehensive treatment of waste gas in polyvinyl alcohol production process

PendingCN110433625AIncrease profitAchieve recyclingDispersed particle separationDistillationPolyvinyl alcohol

The invention discloses an apparatus and a method for recovery of rectification residue effective components and comprehensive treatment of waste gas in a polyvinyl alcohol production process. According to the present invention, the apparatus comprises a residue tank, a U-shaped pipe, a condenser, a vacuum unit, a distillation groove, a distillate discharge pump, a residue pool, an alkali washingtower, an alkali liquid circulating pump, an induced draft fan, an acetylene gas scrubber and an alkali liquid supplementing pump; the method comprises: light component and heavy component separation,light component cooling, and waste gas alkali washing and water washing; and through the effectively utilization and comprehensive treatment of residue components, the utilization rate of raw materials is increased, the production cost is reduced, the recycling of the waste alkali liquid generated in the synthesis section is achieved, and the pollutant discharge is reduced.

Owner:INNER MONGOLIA MENGWEI TECH CO LTD +1

An ethanol product with low acidity

ActiveCN105585428BReduce acetic acid contentImprove qualityOrganic compound preparationHydroxy compound separation/purificationAcetic acidAcid value

An ethanol product with low acidity is provided. The content of ethanol in the ethanol product is 99.9-92 wt%. The acid value calculated based on acetic acid is 0-5 mg / L. The ultraviolet light transmittance is 50-99 at a wavelength of 220 nm.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method that hydrogenation of acetic acid prepares ethanol

ActiveCN105566064BReduce acetic acid contentImprove qualityOrganic compound preparationHydroxy compound separation/purificationAcetic acidHybrid type

The invention provides a method for preparing ethanol by hydrogenation of acetic acid with low energy consumption, comprising the following steps: (1) gas phase hydrogenation; (2) gas-liquid separation; (3) esterification reaction; (4) product refining: the liquid phase Product B is sent to the first rectification tower, and the first bottom fraction is sent to the second rectification tower, and the second tower overhead fraction is partially returned to the hydrogenation reactor described in (1), and partly As a mixed solvent product, the still fraction of the second tower is sent to the neutralization reactor, and an alkaline substance is added for neutralization reaction; the neutralized still fraction of the second tower is sent to the third rectification tower. The method can reduce energy consumption and improve the quality of ethanol products.

Owner:CHINA PETROLEUM & CHEM CORP +3

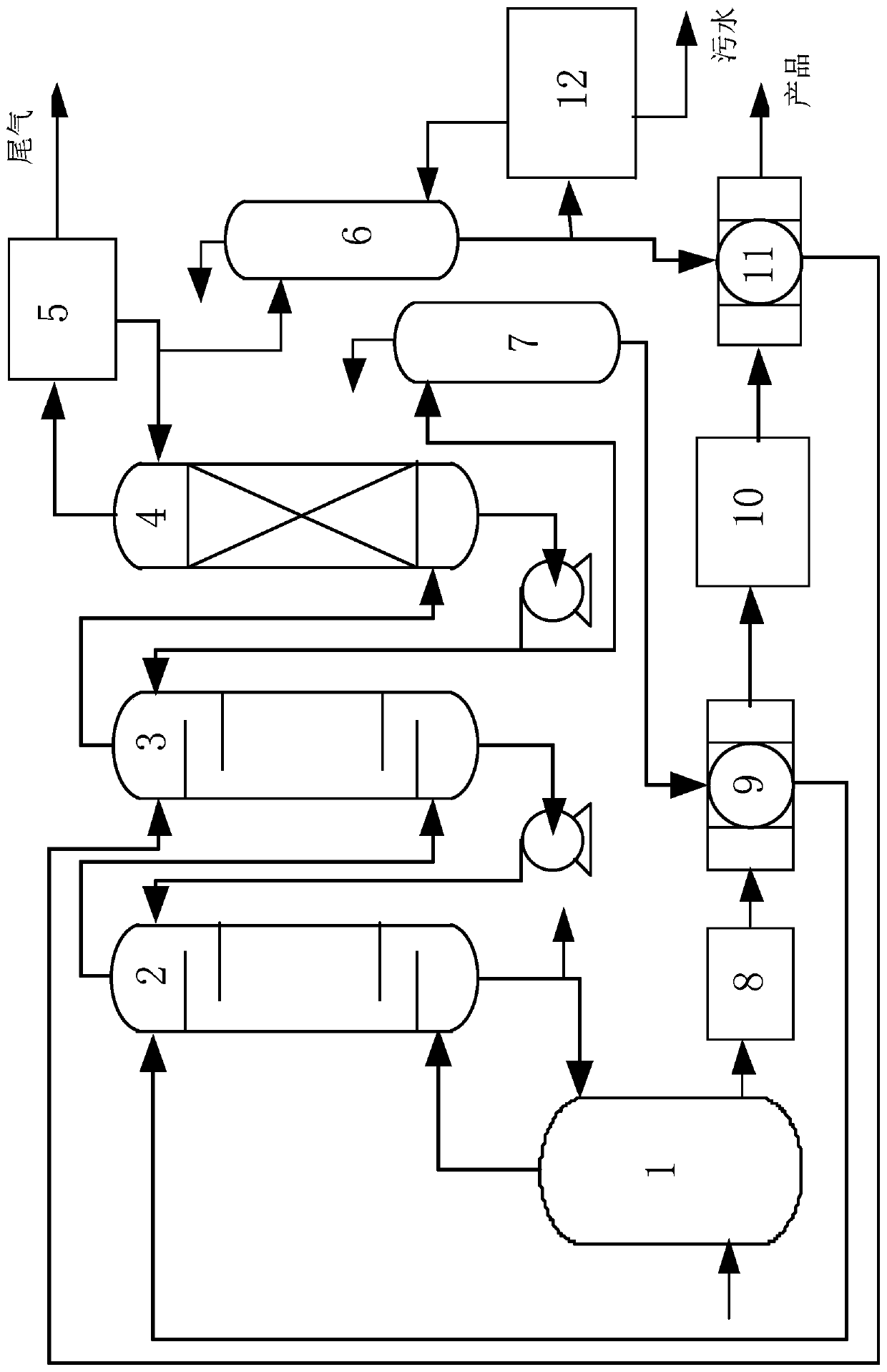

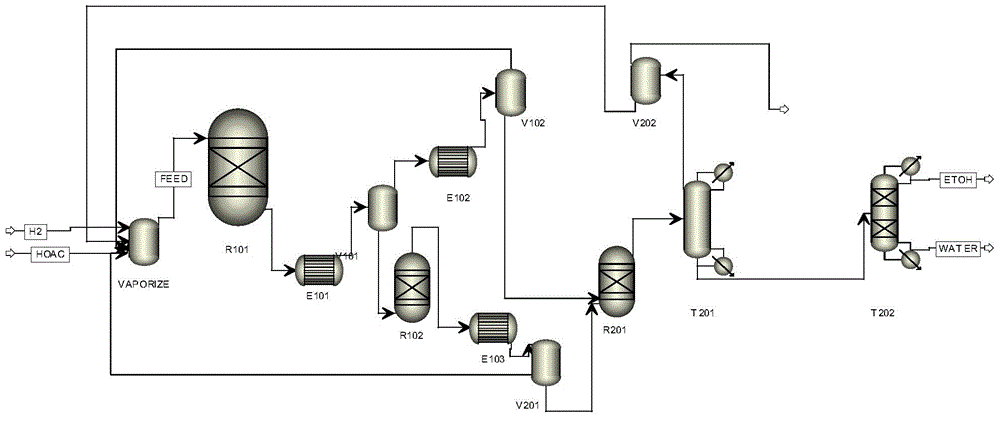

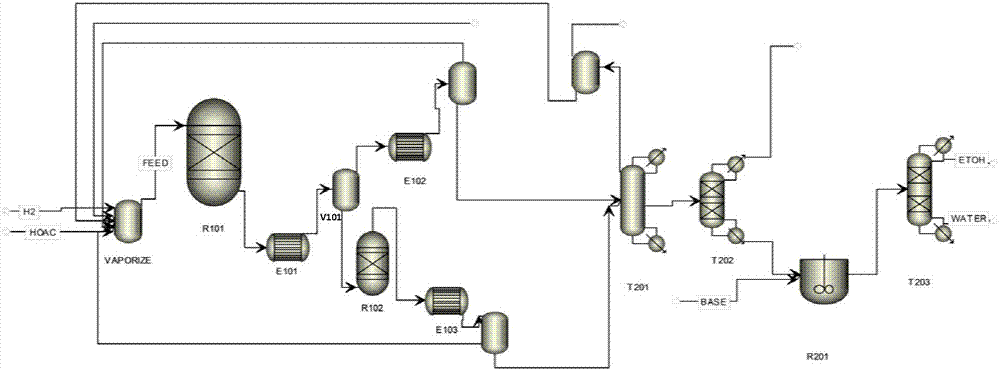

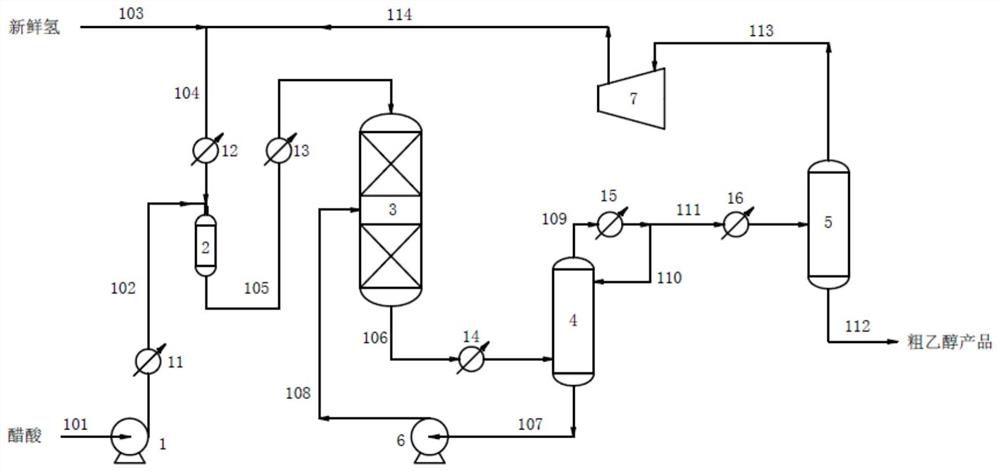

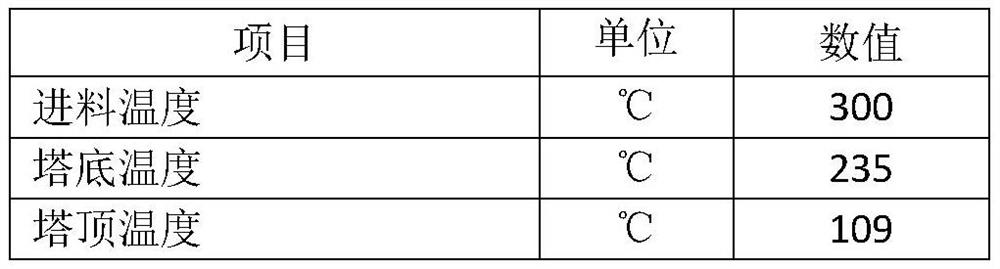

Method for preparing ethanol

ActiveCN110128242BComplete vaporizationWell mixedOrganic compound preparationHydroxy compound preparationAcetic acidFluid phase

The invention relates to the field of ethanol preparation, and discloses a method for preparing ethanol. The acetic acid raw material and hydrogen gas boosted to the reaction pressure are respectively preheated and then enter a spray-type vaporizer for mixed gasification, and the hydrogen and acetic acid mixture flows through heating after gasification. Then it enters the hydrogenation reactor for catalytic hydrogenation reaction, and the reaction product is cooled and then enters the rectification tower, and the liquid phase at the bottom of the tower is separated and obtained as unreacted acetic acid. , and the remaining liquid phase is further cooled into a gas-liquid separator to separate crude ethanol product and tail gas, and the crude ethanol product is purified to obtain ethanol product. The invention has the characteristics of complete vaporization of acetic acid, less corrosiveness to equipment, low energy consumption and equipment investment, low requirements for catalyst conversion rate, and wide applicability.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

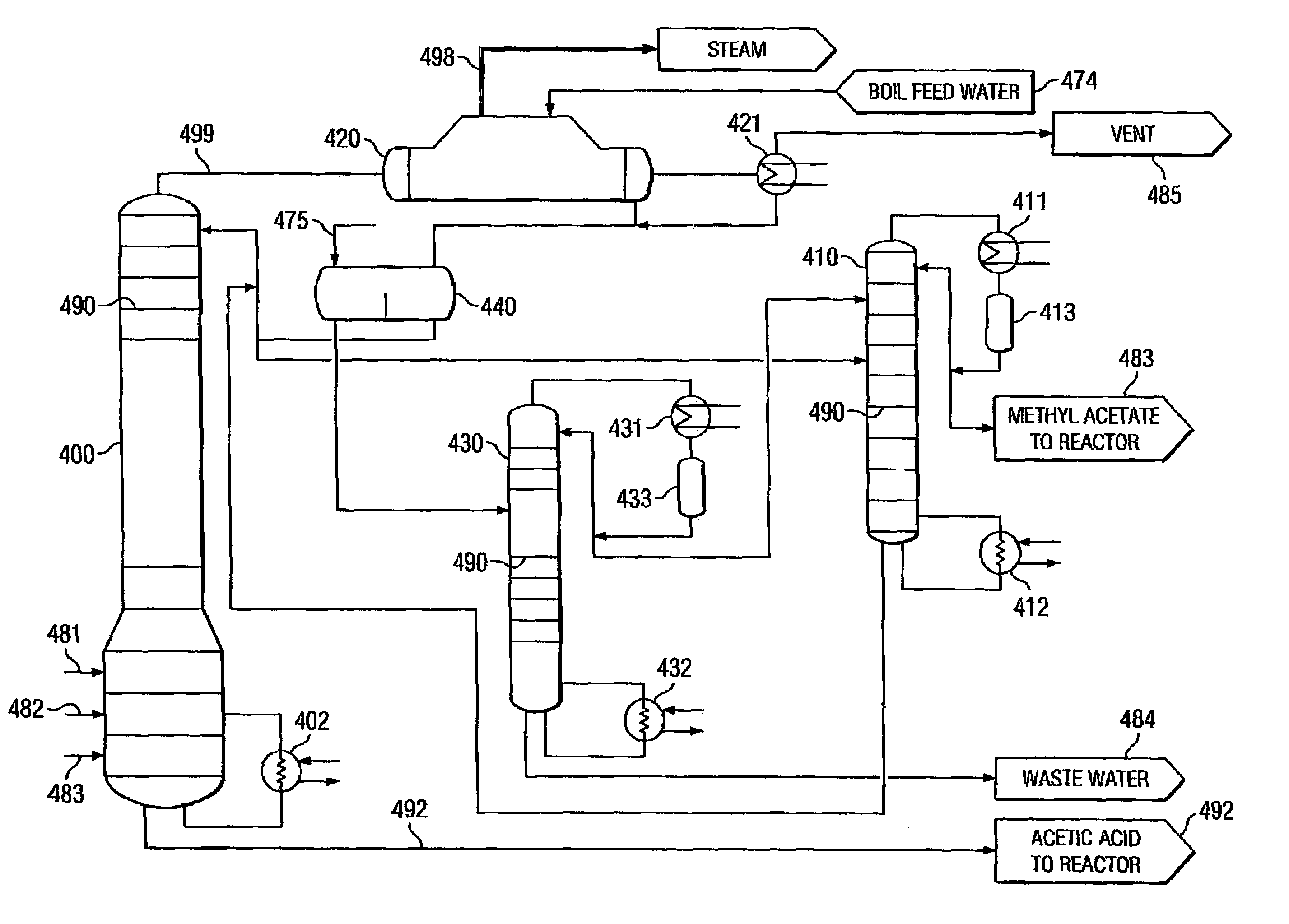

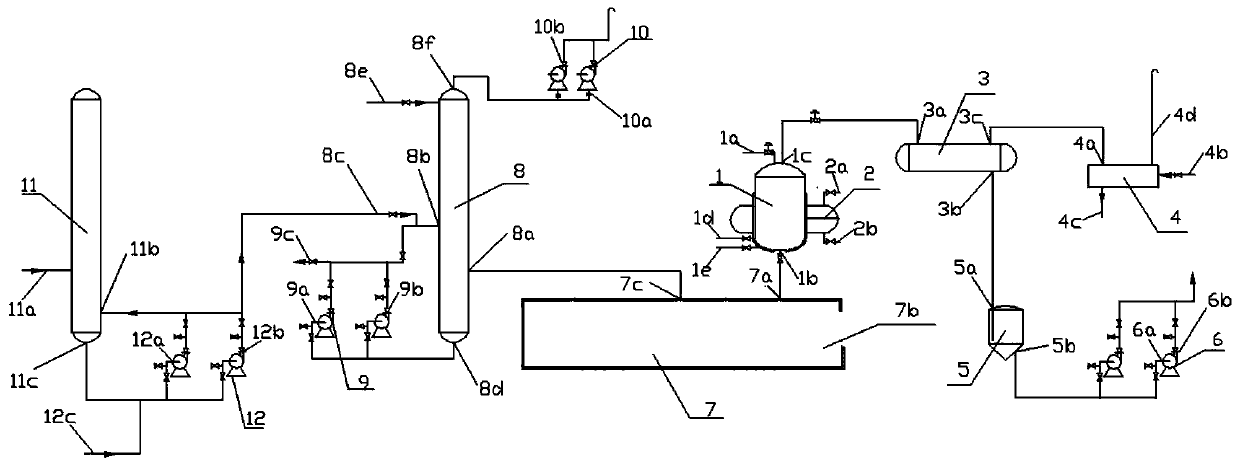

Integrated process for recovering acetic acid and methyl acetate in production process of aromatic carboxylic acid

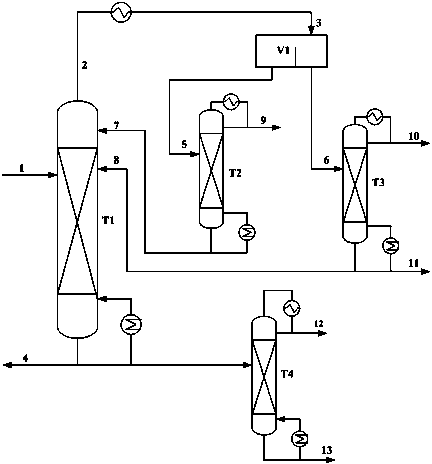

ActiveCN102653512BReduce back flowReduce acetic acid contentOrganic compound preparationCarboxylic acid esters preparationPhase splitterMethyl acetate

The invention relates to an integrated process for recovering acetic acid and methyl acetate in a production process of aromatic carboxylic acid. The integrated process is as follows: water solution of acetic acid from an oxidation unit enters the upper part of a dehydrating tower, steam at the top of the dehydrating tower enters a condenser at the tower top for cooling, and concentrated acetic acid extracted from a tower kettle directly returns to an oxidation reactor; condensed fluid at the top of the dehydrating tower enters a phase splitter and is automatically splitted into an oil phase and a water phase, the oil phase enters an entrainer refining tower, methyl acetate is extracted from the tower top and is recovered, and the entrainer in the tower kettle returns to the top of the dehydrating tower; the water phase enters a methyl acetate recovering tower, methyl acetate extracted from the tower top and methyl acetate at the top of the entrainer refining tower are recovered together, water part in the tower kettle flows back to the top of the dehydrating tower, and part of water is extracted and treated. When the entrainer in the acetic acid of the tower kettle of the dehydrating tower is higher than 5 percent, the tower kettle material firstly enters an entrainer separating tower, the condensed acetic acid extracted from the tower top returns to the oxidation reactor, and excess entrainer is separated from the tower kettle. By utilizing the process, the quantity of the entrainer flowing back can be greatly reduced, and the oxidation reaction can be stably performed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fractional Utilization Emission Reduction System of Water-rich Solvent for Preparation of Terephthalic Acid

ActiveCN110078284BReduce energy consumptionEffectively regulate moisture contentOrganic compound preparationSpecific water treatment objectivesBenzoic acidDistillation

The invention discloses a water-rich solvent graded utilization emission reduction system for preparing terephthalic acid, which includes multiple units such as oxidation reaction, rectification and dehydration, oxidation and refining filtration, solvent stripping, and multi-effect distillation. Through the optimized allocation of materials, the use of water-rich solvents with different grades of acetic acid concentrations in grades can greatly reduce the amount of fresh water and reduce the organic matter content in the discharge liquid under the premise of ensuring product quality and effective use of reaction heat. The technical key lies in: (1) The dehydration unit is equipped with a three-stage rectification tower, and the water-rich solvent produced by each unit in the oxidation and refining process is refluxed into the rectification tower at each level according to the concentration matching rules, and the water-rich solvent obtained by rectification is in accordance with the concentration requirements of different acetic acid They are respectively used for oxidation filter washing, refining filter washing, exhaust gas spraying, etc.; (2) Use the low-pressure steam produced by the system to perform multi-effect distillation on the discharge liquid, fully recover the acetic acid in the discharge liquid, and reduce the consumption of acetic acid in the system.

Owner:杭州多向流化学科技有限公司 +1

A kind of method for hydrogenation of acetic acid to produce ethanol

ActiveCN105566057BReduce acetic acid contentImprove qualityOrganic compound preparationHydroxy compound preparationAcetic acidDistillation

The invention provides a method for producing ethanol by hydrogenation of acetic acid with low energy consumption, which comprises the following steps: (1) gas phase hydrogenation; (2) gas-liquid separation; (3) esterification reaction; (4) product refining: the liquid phase Product B is sent to the neutralization reactor, and alkaline substances are added for neutralization reaction. The neutralized product enters the first rectification tower, and the first tower overhead fraction contains acetaldehyde, ethyl acetate, acetone, and the first tower bottom fraction It is a crude ethanol product containing ethanol and water. The first tower overhead fraction is partially returned to the gas phase hydrogenation reactor, and the first tower bottom fraction is sent to the second rectification tower. The second tower overhead fraction contains ethanol and water. The bottoms fraction contains water, ethanol, butanol and acetate. The method can reduce energy consumption and improve the quality of ethanol products.

Owner:CHINA PETROLEUM & CHEM CORP +1

A photovoltaic encapsulation material eva adhesive film resistant to potential induced attenuation

ActiveCN108034372BImprove anti-PID performanceHigh volume resistivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesLow-density polyethylenePolymer science

Owner:福斯特(滁州)新材料有限公司

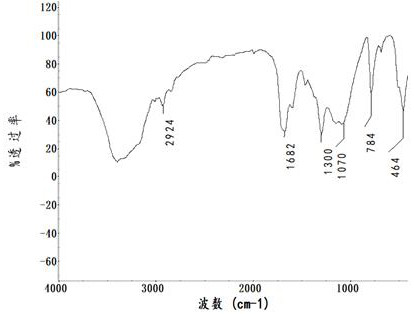

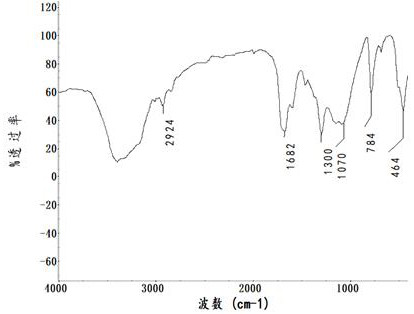

Preparation method of optical cellulose triacetate

ActiveCN102936289BHigh performance featuresExcellent optical propertiesAcetic acidBiological activation

The invention discloses a preparation method of optical cellulose triacetate, belonging to the technical field of high polymer chemistry. The method comprises the following steps of: (1) crushing of the refined cotton; (2) drying of the refined cotton; (3) activation; (4) esterification; (5) neutralization; (6) dilution and bleaching; (7) filtering, precipitation, wet crushing and washing; (8) drying; and (9) granulation. The method disclosed by the invention can reduce the ash content and acetic acid content of the cellulose triacetate and improve the mechanical properties and optical characteristics of a cellulose triacetate membrane; and the prepared cellulose triacetate has uniform particles and low viscosity and can be quickly dissolved.

Owner:XIAN NORTH HUIAN CHEM IND CO LTD

Method for preparing ethanol by hydrogenation of acetic acid

ActiveCN105566060BReduce acetic acid contentImprove qualityOrganic compound preparationHydroxy compound preparationLiquid productEthylic acid

The invention provides a low-energy consumption method for preparing ethanol through acetic acid hydrogenation. The method comprises 1, gas phase hydrogenation, 2, gas-liquid separation, 3, esterification reaction and 4, product refining: feeding a liquid product B into a first rectifying tower, feeding a part of the first rectifying tower top fraction containing acetaldehyde, ethyl acetate and acetone back to a gas phase hydrogenation reactor, feeding the first rectifying tower bottom fraction as a crude ethanol product containing ethanol, ethyl acetate and water into a neutralization reactor, adding an alkaline substance into the neutralization reactor, carrying out a neutralization reaction process, feeding the neutralized first rectifying tower bottom fraction into a second rectifying tower, and carrying out separation to obtain a second rectifying tower top fraction containing ethanol and water and a second rectifying tower top fraction containing water, butanol and acetate, wherein the second rectifying tower top fraction has ethanol content of 85-95wt% and an acidity value of 0-25mg / L. The method can reduce energy consumption and improve ethanol product quality.

Owner:CHINA PETROLEUM & CHEM CORP +3

Sterilization and clarification method of aged lychee alcoholic beverage

ActiveCN111961559BIncrease the juice yieldIncrease productionImmobilised enzymesAlcoholic beverage preparationBiotechnologySucrose

The invention discloses a sterilization and clarification method of an aged litchi alcoholic beverage, and relates to the field of sterilization, purification, clarification and aging of alcoholic beverages, and the method comprises the following steps: (1) litchi treatment, (2) litchi juice sterilization treatment: adding sucrose and malic acid into litchi juice, adjusting sugar degree and pH, and adding dimethyl dicarbonate, and treating at normal temperature to obtain sterilized litchi juice; (3) litchi juice fermentation: uniformly mixing the sterilized litchi juice, saccharomycetes, citric acid, amino acids, preservatives, vitamins and absolute ethyl alcohol, and performing sealed fermentation to obtain the litchi alcoholic beverage; (4) clarifying the litchi alcoholic beverage: adding bentonite into the litchi raw wine, uniformly stirring, standing, taking supernate, and filtering to obtain clarified wine liquid; and (5) wine liquid aging process: heating the clarified wine liquid to 70 DEG C, keeping the temperature for 10 minutes, quickly cooling to-7-0 DEG C, and keeping the temperature for 5-15 days to obtain the aged litchi alcoholic beverage.

Owner:福建泉智生物科技有限公司

An ethanol product with low acidity

ActiveCN105585428AReduce acetic acid contentImprove qualityOrganic compound preparationHydroxy compound separation/purificationAcetic acidAcid value

An ethanol product with low acidity is provided. The content of ethanol in the ethanol product is 99.9-92 wt%. The acid value calculated based on acetic acid is 0-5 mg / L. The ultraviolet light transmittance is 50-99 at a wavelength of 220 nm.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vacuum low-temperature drying method for cattle bone glue

ActiveCN107823896AReduce acetic acid contentReduce energy consumptionEvaporationAcetic acidMicrowave

The invention discloses a vacuum low-temperature drying method for a cattle bone glue. The vacuum low-temperature drying method comprises the following steps: 1) raw material preparation: a step of filling a concentrate of a cattle bone glue extract into a container, wherein the volume of the concentrate of the cattle bone glue extract is V1, the volume of the container is V2, and the ratio of V1to V2 is no more than 20%; and 2) vacuum drying: a step of placing the container in the step 1) into a microwave vacuum drying device, carrying out heating, allowing the concentrate of the cattle boneglue extract to be in a low-temperature boiling state, allowing water vapor and acetic acid to be sucked away by a vacuum pump, and subjecting the cattle bone glue extract to concentration and dryingso as to obtain the cattle bone glue. The vacuum low-temperature drying method provided by the invention has the characteristics of low acetic acid content, low energy consumption, short drying time,high product yield and high production efficiency.

Owner:GUANGDONG JIMIN PHARMA IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com