Fractional Utilization Emission Reduction System of Water-rich Solvent for Preparation of Terephthalic Acid

A terephthalic acid and water solvent technology, applied in the field of water-rich solvent graded utilization emission reduction system, can solve the problems of unreasonable selection of mother liquor reflux position, lower distillation separation efficiency, and more acetic acid loss, so as to save consumption and reduce Effects of energy consumption and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

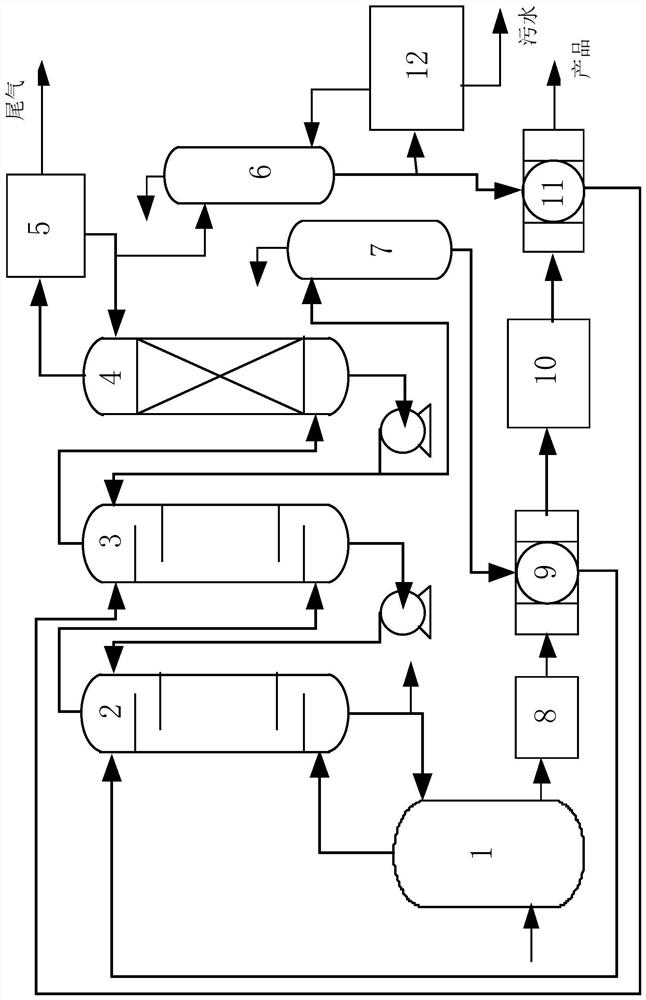

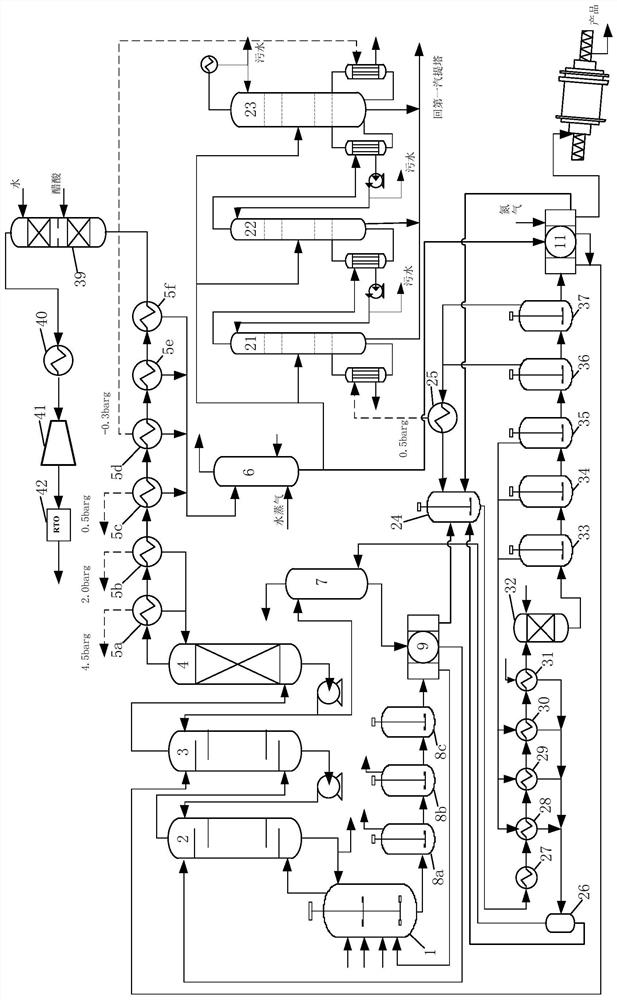

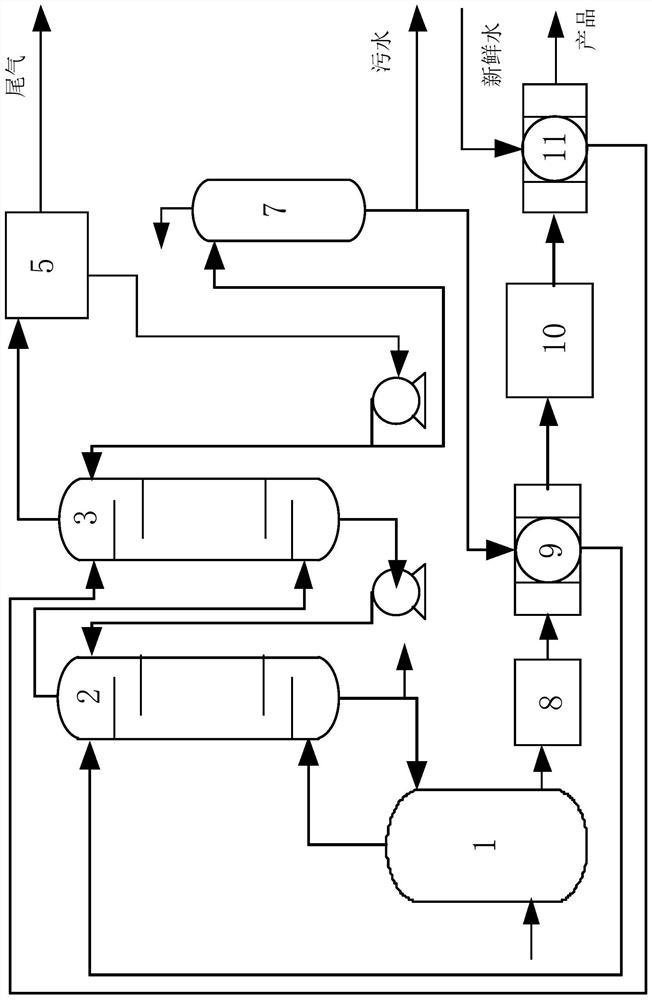

[0057] The process flow of the water-rich solvent classification utilization emission reduction system used to prepare terephthalic acid in this embodiment is as follows figure 2 As shown, it mainly includes: oxidation reactor unit, dehydration rectification unit, energy recovery unit 5, oxidation crystallization unit, oxidation filtration unit, refining batching unit, hydrogenation and crystallization unit, refining filtration and drying unit, water solvent stripping unit , multi-effect evaporation unit and other subsystems.

[0058]Oxidation reactor unit: the p-xylene raw material is sent to the oxidation reactor 1 through the pipeline, and the filtrate from the oxidation filter 9 provides a circulating mother liquor, which contains a small amount of uncrystallized terephthalic acid and a large amount of solvent acetic acid and recycled In addition, a small amount of catalyst is added to the oxidation reactor 1. The compressed air is passed into the oxidation reactor 1 thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com