Methyl acetate molecular sieve catalyst prepared by carbonylation of dimethyl ether, modification method and application

A methyl acetate, molecular sieve technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as catalyst activity and selectivity reduction, and achieve improved selectivity, reduced production costs, and high selectivity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present embodiment provides the method for modifying the dimethyl ether carbonylation to produce methyl acetate molecular sieve catalyst of the present invention, and the specific steps are as follows:

[0040] Step 1: Add 200g SiO 2 / Al 2 o 3 Powdered hydrogen mordenite molecular sieves with a ratio of 20:1 were calcined at 500°C for 4 hours in a dry air atmosphere.

[0041] Step 2: At 250°C, use N 2 Bubble liquid pyridine through hydrogen mordenite molecular sieves for 2 hours, then N 2 Purge for 2 hours and cool to room temperature.

[0042] Step 3: The sample after pyridine modification is placed in 0.1mol / L Cu(NO 3 ) 2 In salt solution, stir at 50°C for 4 hours, then filter, wash, dry, and finally bake at 500°C for 4 hours in a dry air atmosphere.

[0043] Step 4: At 250°C, use N 2 Bubble liquid pyridine through hydrogen mordenite molecular sieves for 2 hours, then N 2 Purge for 2 hours, cool down to room temperature, and seal for later use. The obtai...

Embodiment 2

[0047] This embodiment provides the method for modifying the molecular sieve catalyst for producing methyl acetate by carbonylation of dimethyl ether of the present invention. Compared with Example 1, only the modification temperature of pyridine in step 2 and step 4 is set to 270°C. The rest of the conditions are the same. The modified catalyst was named MOR-2.

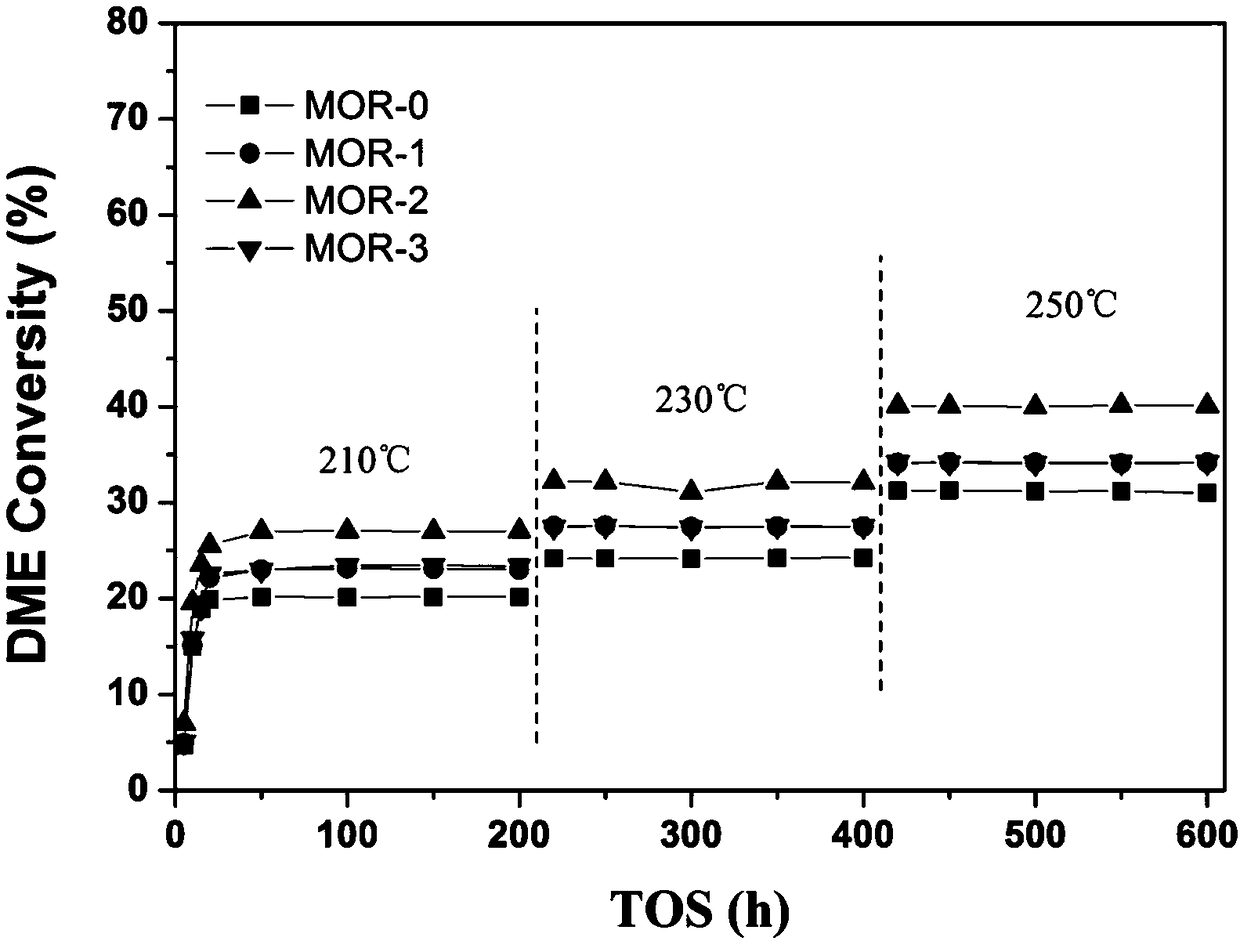

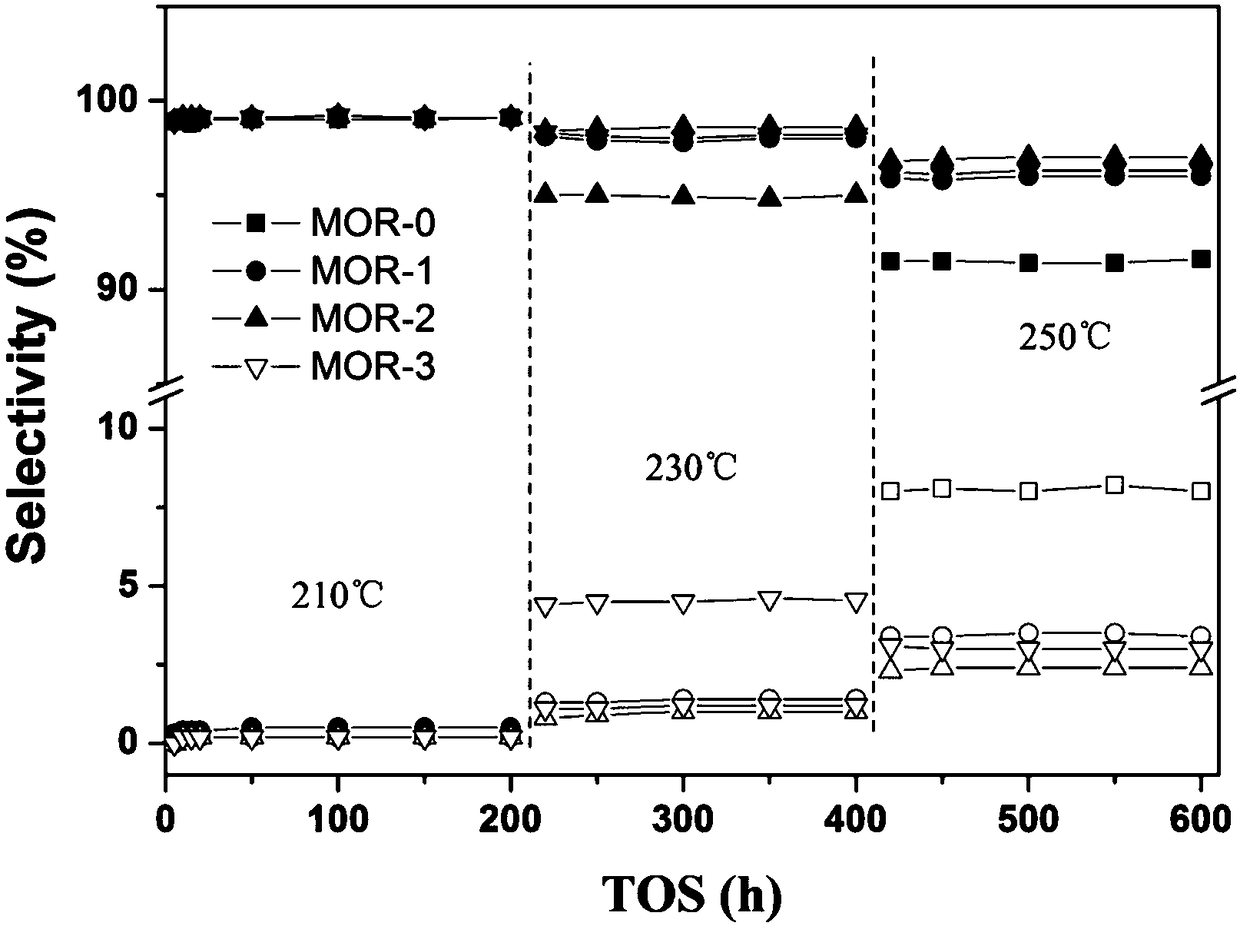

[0048] The activity testing method of catalyst after the modification of this embodiment is with embodiment 1, and test result sees Figure 1a with Figure 1b .

Embodiment 3

[0050] This embodiment provides the method for modifying the molecular sieve catalyst for producing methyl acetate by carbonylation of dimethyl ether of the present invention. Compared with Example 1, only the modification temperature of pyridine in step 2 and step 4 is set to 290°C. The rest of the conditions are the same. The modified catalyst was named MOR-3.

[0051] The activity testing method of catalyst after the modification of this embodiment is with embodiment 1, and test result sees Figure 1a with Figure 1b .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com