Ethyl alcohol and acetic ether-containing mixed solvent

An ethyl acetate and mixed solvent technology, applied in the field of mixed solvent products, can solve problems such as high material requirements, unqualified products, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The following examples are illustrative descriptions of the present invention in more detail, but the present invention is not limited to these examples.

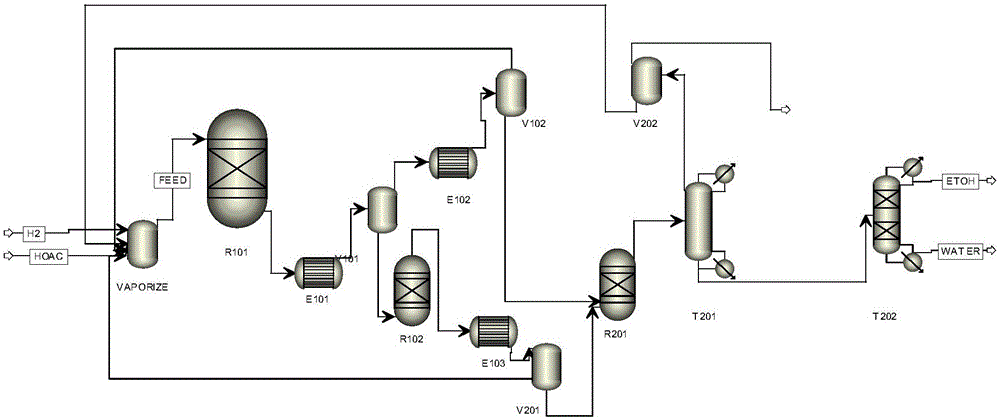

[0059] In this embodiment, the specific flow chart is as figure 1 shown.

[0060] First, preheat the acetic acid raw material, return material and hydrogen to form a steam feed stream, and introduce the steam feed stream into the reactor R101 equipped with a gas-phase hydrogenation catalyst. The catalyst for the gas-phase hydrogenation of acetic acid is produced by Beijing Research Institute of Chemical Industry The acetic acid hydrogenation catalyst (1) cobalt, wherein cobalt metal content accounts for 24wt% of catalyst gross weight; (2) molybdenum and tin, respectively account for 3wt% and 30wt% of catalyst gross weight; (3) boron and bismuth, respectively account for 2wt% and 5wt% of the total weight of the catalyst, and the balance is silicon dioxide. Acetic acid is hydrogenated to crude ethanol product. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com