Method for producing vinyl acetate

A production method and vinyl acetate technology are applied in chemical instruments and methods, preparation of carboxylate, preparation of organic compounds, etc., and can solve the problems of unfavorable economy, low conversion rate of ethylene per pass, and high reaction temperature, and reduce production costs, The effect of increasing the explosion limit and lowering the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

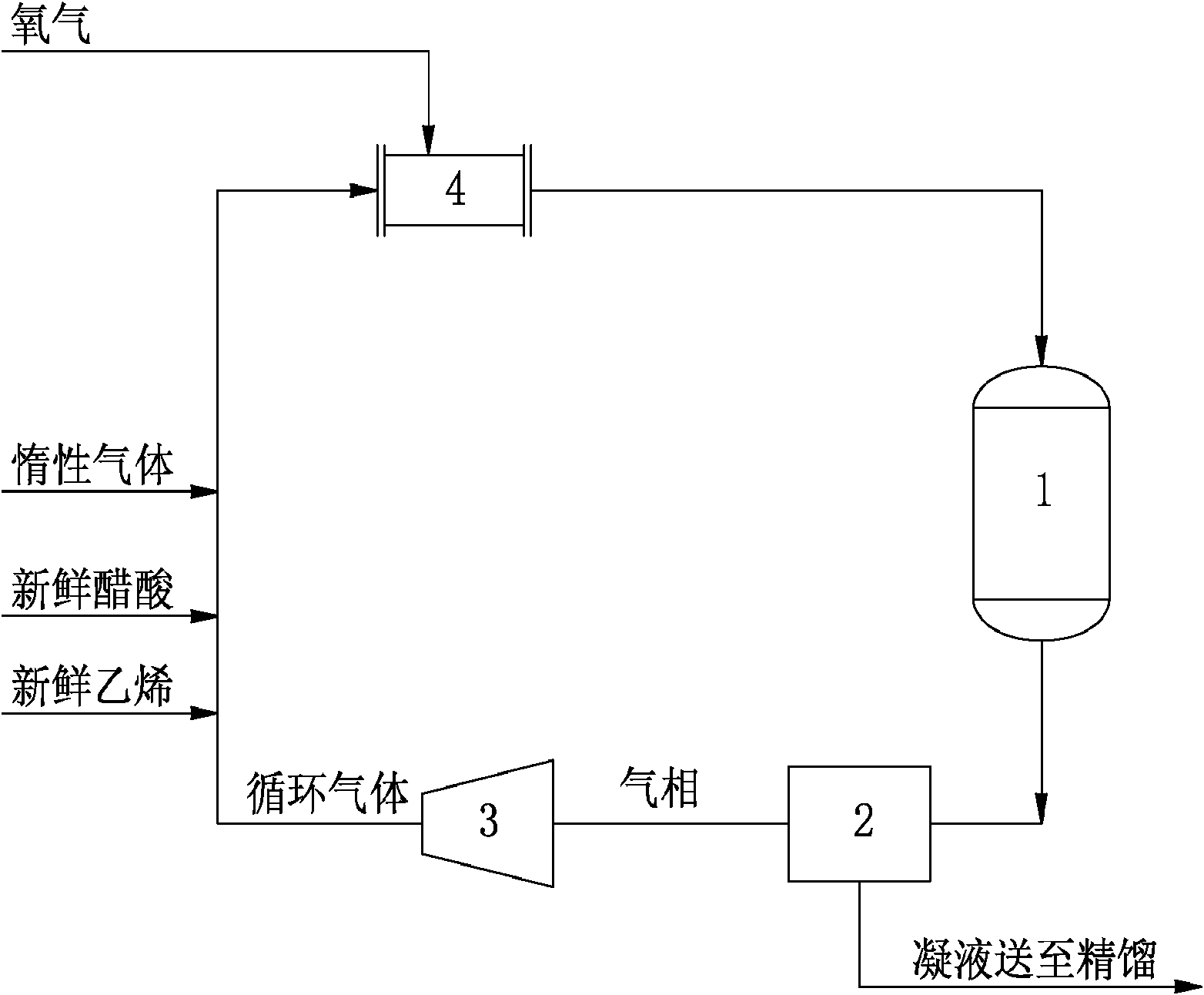

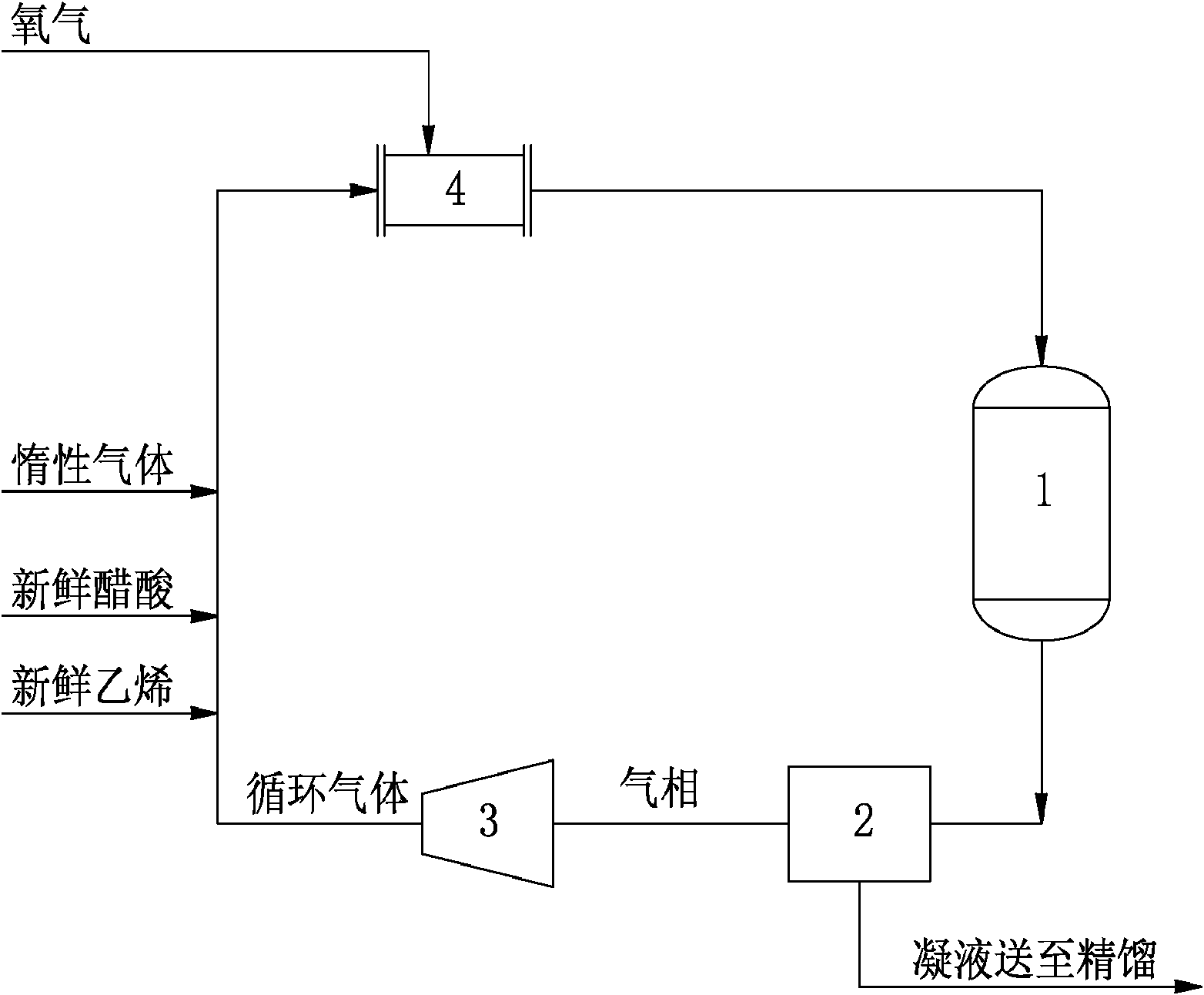

[0019] In the production of vinyl acetate, oxygen is mixed with the circulating gas containing ethylene and acetic acid through the oxygen mixer 4, and the mixed gas enters the reactor 1 for reaction. After the reaction, the high-temperature reaction gas is condensed through the condensation system 2, and the uncondensed gas phase is passed through the circulating gas compressor. 3. Cycle after boosting. Nitrogen is added in the circulating gas, and the nitrogen concentration of the control reactor inlet is 30% (mol%), and the oxygen concentration of the reactor inlet is increased to 12% (mol%) this moment, and at the initial stage of catalyst use, the reaction temperature is 110 ° C; In the mid-use period, the reaction temperature is 150°C; in the late use of the catalyst, the reaction temperature is 180°C. 20°C lower than the original process. Vinyl acetate selectivity was 96%, a 3% improvement.

Embodiment 2

[0021] In the production of vinyl acetate, oxygen is mixed with the circulating gas containing ethylene and acetic acid through the oxygen mixer 4, and the mixed gas enters the reactor 1 for reaction. After the reaction, the high-temperature reaction gas is condensed through the condensation system 2, and the uncondensed gas phase is passed through the circulating gas compressor. 3. Cycle after boosting. Nitrogen is added in the circulating gas, and the nitrogen concentration of the control reactor inlet is 15% (mol%), and the oxygen concentration of the reactor inlet is increased to 11.4% (mol%) at this moment, and at the initial stage of catalyst use, the reaction temperature is 120 ° C; In the mid-use period, the reaction temperature is 160°C; in the late use period of the catalyst, the reaction temperature is 190°C. 10°C lower than the original process. Vinyl acetate selectivity was 95%, a 2% improvement.

Embodiment 3

[0023] In the production of vinyl acetate, oxygen is mixed with the circulating gas containing ethylene and acetic acid through the oxygen mixer 4, and the mixed gas enters the reactor 1 for reaction. After the reaction, the high-temperature reaction gas is condensed through the condensation system 2, and the uncondensed gas phase is passed through the circulating gas compressor. 3. Cycle after boosting. Nitrogen is added in the circulating gas, and the nitrogen concentration of the control reactor inlet is 8% (mol%), and this moment, the oxygen concentration of the reactor inlet is increased to 10.5% (mol%), and at the initial stage of catalyst use, the reaction temperature is 125°C; In the mid-use period, the reaction temperature is 165°C; in the late use period of the catalyst, the reaction temperature is 195°C. 5°C lower than the original process. The vinyl acetate selectivity was 93.5%, an increase of 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com