Apparatus and method for recovery of rectification residue effective components and comprehensive treatment of waste gas in polyvinyl alcohol production process

A production process, polyvinyl alcohol technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as incompatibility, waste of sodium hydroxide solution, etc., and achieve improved utilization, recycling and treatment devices Simplicity and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

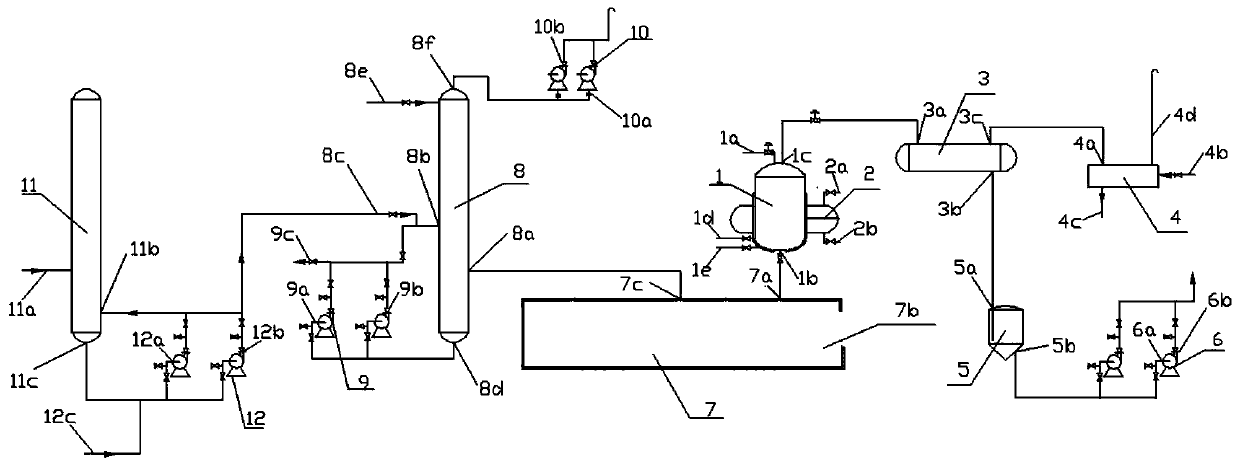

[0054] Such as figure 1 As shown, the present embodiment first sets the following devices:

[0055] Including residue tank 1, U-shaped pipe 2, condenser 3, vacuum unit 4, distillation tank 5, distillate delivery pump 6, residue pool 7, alkali washing tower 8, alkali circulation pump 9, induced draft fan 10, acetylene Gas scrubber 11, lye replenishment pump 12.

[0056] A jacket for feeding steam is provided outside the residue tank 1, a residue inlet 1a, a residue material outlet 1b, and a residue tank gas phase outlet 1c are arranged on the residue tank 1; a residue tank jacket steam is provided on the jacket. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com