Method for preparing high-quality ethanol through hydrogenating acetic acid

A hydrogen preparation and ethyl acetate technology, which is applied in the field of ethanol preparation, can solve the problems of high energy consumption, difficulty, and serious liquid phase corrosion of the system, and achieve the effects of reducing the content of acetic acid, reducing energy consumption, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this example, the catalyst for gas-phase hydrogenation of acetic acid is the acetic acid hydrogenation catalyst produced by Beijing Research Institute of Chemical Industry, the brand is BC-E-20, and the catalyst contains: (1) cobalt, wherein the cobalt metal content accounts for 30wt of the total weight of the catalyst %; (2) molybdenum and chromium account for 2wt% of the total catalyst weight respectively; the balance is silicon oxide. The catalyst is prepared by co-precipitation. The catalyst for liquid-phase hydrogenation of acetic acid is a ruthenium-rhenium-potassium catalyst supported by activated carbon.

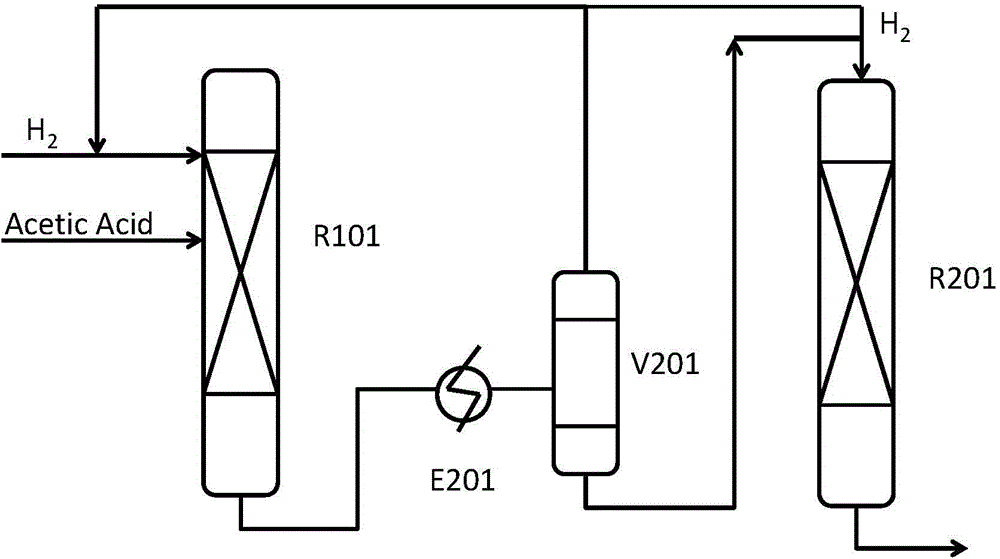

[0047] The specific flow chart is attached figure 1 shown

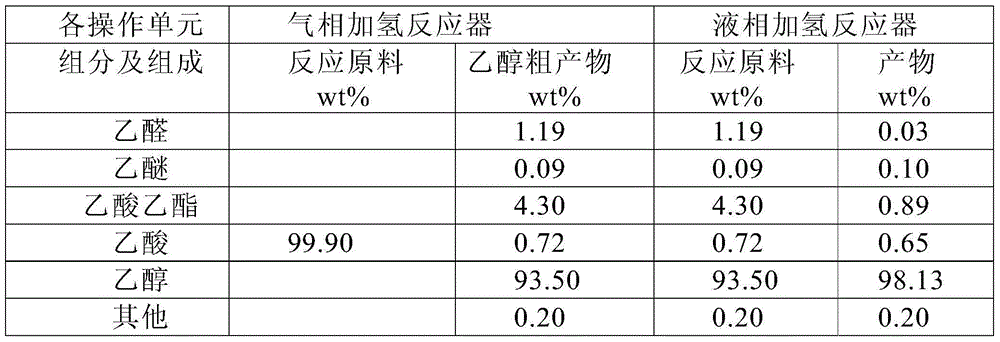

[0048] (1) Gas-phase hydrogenation: Preheat the acetic acid raw material and hydrogen to form a steam feed stream, which is introduced into the reactor R101 equipped with a gas-phase hydrogenation catalyst to hydrogenate the acetic acid into crude ethanol product. The process condition of acetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com