Method for removing acetic acid in sucrose-6-acetate solution and application thereof

A technology of acetate and sucrose, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of high price, large quantity, and high manufacturing cost of sucralose, and achieve good fluidity and continuous operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

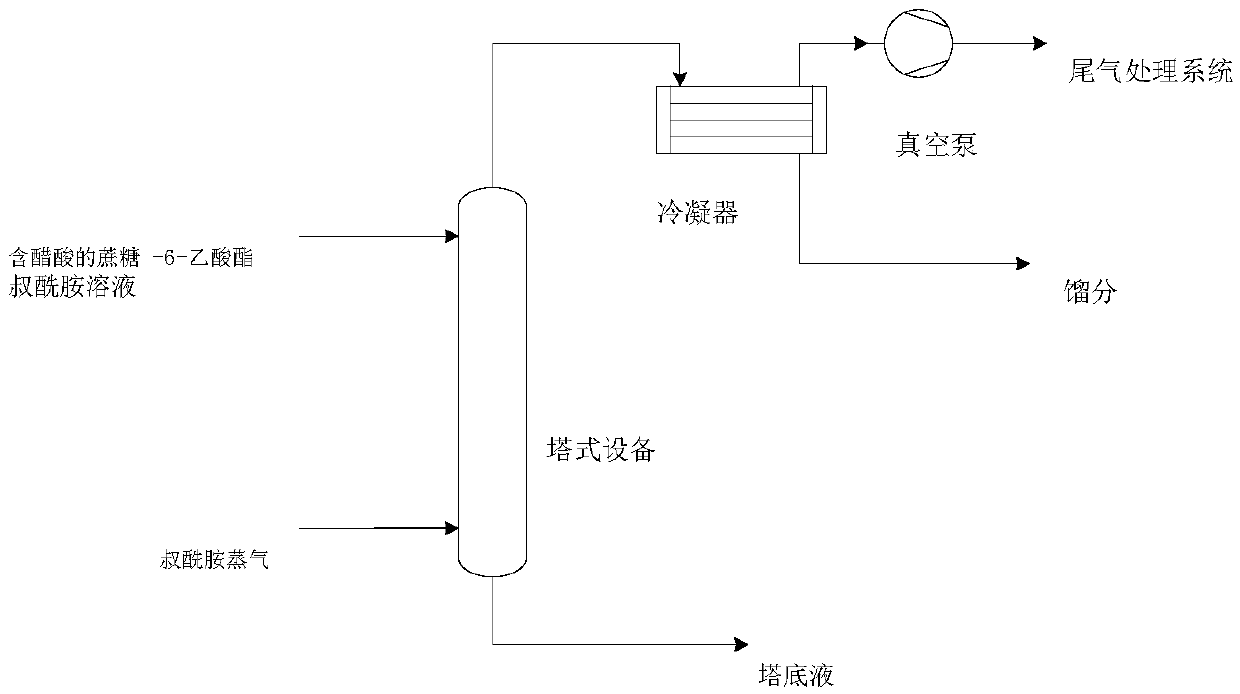

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Using a packed tower to remove acetic acid, the packing is BX packing

[0046] Turn on the electric heating cable to preheat the packed tower. When the temperature of the heating cable rises to about 75°C, turn on the vacuum system to maintain the absolute pressure at the top of the tower at 4.5kPa, and pass 65°C DMF steam into the packed tower. The prepared sucrose-6-acetate DMF solution (the composition of the raw material liquid is shown in the table below) is passed into the position near the top of the side wall, and the top and bottom of the tower are continuously collected from the top and bottom of the tower (or called tower Kettle) liquid, keep the feed ratio of DMF vapor to sucrose-6-acetate DMF solution at 3:1 (by weight) and flow rates of 3Kg / h and 1Kg / h respectively; after 8 hours of continuous operation, it corresponds to each kilogram As far as the feed liquid of the sucrose-6-acetate DMF solution is concerned, 0.95 kg of column bottom solution is...

Embodiment 2

[0051] Example 2: Using a packed tower to remove acetic acid, the packing is BX packing

[0052] Turn on the electric heating cable to preheat the packed tower. When the temperature of the heating cable rises to about 85°C, turn on the vacuum system to maintain the absolute pressure at the top of the tower at 5.0kPa, and pass 75°C DMF steam into the packed tower. The prepared sucrose-6-acetate DMF solution (the composition of the raw material liquid is shown in the table below) is passed through the side wall near the top, and the top and bottom liquids are continuously collected from the top and bottom of the tower. DMF vapor and The feed flow rate of the sucrose-6-acetate DMF solution is 4Kg / h and 1Kg / h respectively; after 6.5 hours of continuous operation, 1.2Kg per kilogram of sucrose-6-acetate DMF solution is produced. Bottom solution. The components of the top and bottom liquids were measured separately.

[0053] The composition of the raw material liquid, the top of the to...

Embodiment 3

[0057] Example 3: Use a packed tower to remove acetic acid, the packing is Raschig ring

[0058] Turn on the electric heating cable to preheat the packed tower. When the temperature of the heating cable rises to about 75°C, turn on the vacuum system to maintain the absolute pressure at the top of the tower at 4.5kPa, and pass 65°C DMF steam into the packed tower. The prepared sucrose-6-acetate DMF solution (the composition of the raw materials is shown in the table below) is passed through the side wall near the top, and the top and bottom liquids are continuously collected from the top and bottom of the tower to keep the DMF vapor and The feed flow rate of the sucrose-6-acetate DMF solution is 4Kg / h and 1Kg / h respectively; after 5.5 hours of continuous operation, 1.1Kg per kilogram of sucrose-6-acetate DMF solution is produced. Bottom solution. The components of the top and bottom liquids were measured separately.

[0059] The composition of the raw material liquid, the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com