A kind of vacuum low-temperature drying method of bovine bone glue

A vacuum low-temperature drying and bovine bone technology, which is applied in the field of bovine bone glue, can solve the problems of high acetic acid content, large loss, and low efficiency, and achieve the effects of low acetic acid content, high production efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A vacuum low-temperature drying method for bovine bone glue, comprising the following steps:

[0043] 1) Raw material preparation step: put the bovine bone glue extract concentrate into a container, wherein the volume of the bovine bone glue extract concentrate is V1, the volume of the container is V2, V1: V2=20%; the bovine bone glue extract The moisture content of the concentrate is 70%;

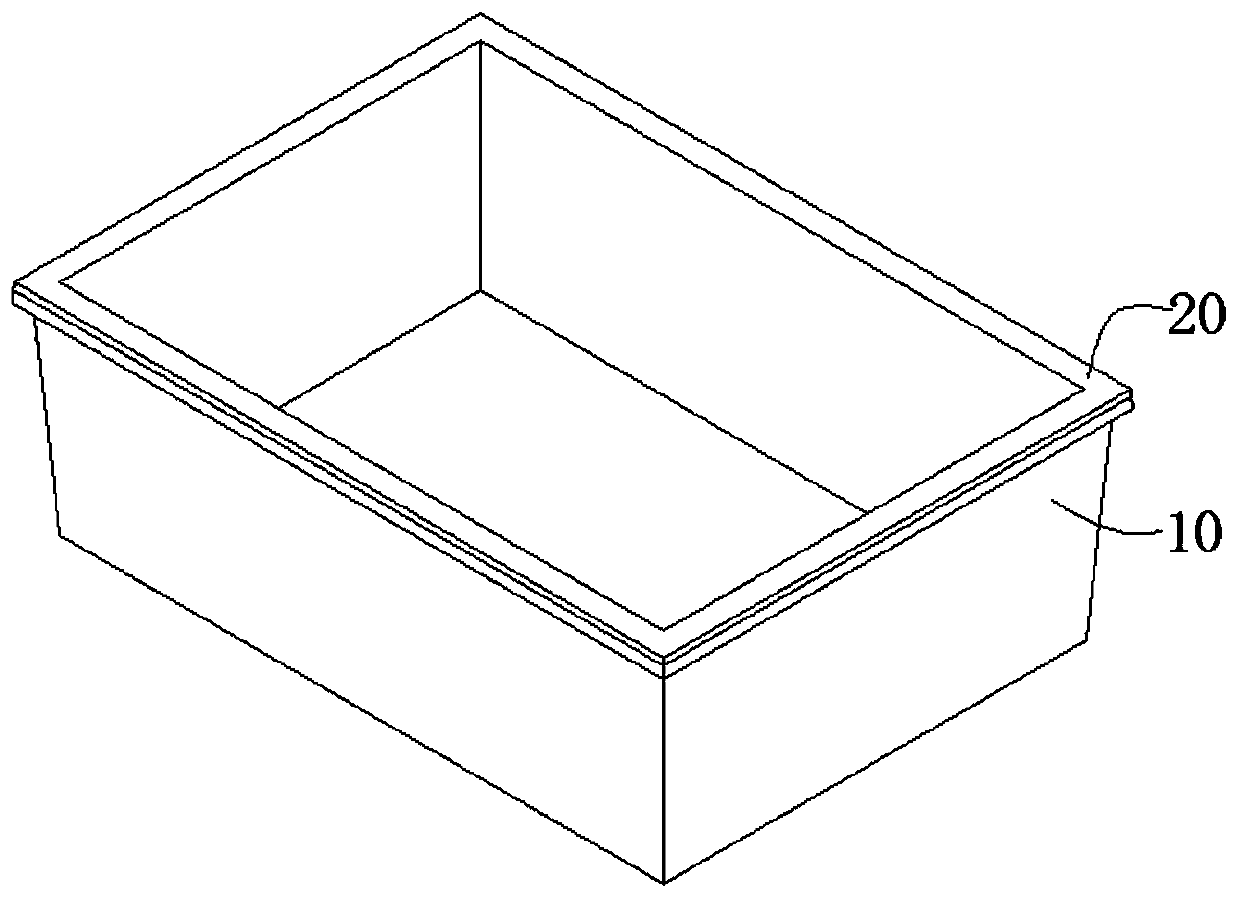

[0044] refer to figure 1 , the container is a plastic tray 10 covered with a silicone sleeve 20.

[0045] 2) Vacuum drying steps:

[0046] 2-1) First put the container of step 1) into a static vacuum microwave dryer for preheating, so that the bovine bone glue extract concentrate is in a boiling state; control the boiling degree of the bovine bone glue extract concentrate by adjusting the vacuum degree to prevent bovine bone glue extract from boiling The bone glue extract concentrate boils and overflows the container, and the shrinkage liquid boils and overflows the container. Ad...

Embodiment 2

[0050] A vacuum low-temperature drying method for bovine bone glue, comprising the following steps:

[0051] 1) Raw material preparation step: put the bovine bone glue extract concentrate into a container, wherein the volume of the bovine bone glue extract concentrate is V1, the volume of the container is V2, V1: V2=15%; the bovine bone glue extract The water content of the concentrated solution is 70%; the container is a plastic plate covered with a silica gel sleeve.

[0052] 2) Vacuum drying steps:

[0053] 2-1) First put the container of step 1) into a static vacuum microwave dryer for heating, so that the bovine bone glue extract concentrate is in a boiling state; control the boiling degree of the bovine bone glue extract concentrate by adjusting the vacuum degree to prevent bovine bone glue The extract concentrate boils and overflows the container, and the shrinkage liquid boils and overflows the container. The vacuum degree is adjusted by adjusting the opening of the v...

Embodiment 3

[0057] A vacuum low-temperature drying method for bovine bone glue, comprising the following steps:

[0058] 1) Raw material preparation step: put the bovine bone glue extract concentrate into a container, wherein the volume of the bovine bone glue extract concentrate is V1, the volume of the container is V2, V1: V2=10%; the bovine bone glue extract The water content of the concentrated solution is 70%; the container is a plastic plate covered with a silica gel sleeve.

[0059] 2) Vacuum drying steps:

[0060] 2-1) First put the container of step 1) into a static vacuum microwave dryer for heating, so that the bovine bone glue extract concentrate is in a low-temperature boiling state; control the boiling degree of the bovine bone glue extract concentrate by adjusting the vacuum degree to prevent bovine bone glue extract from boiling The bone glue extract concentrate boils and overflows the container, and the shrinkage liquid boils and overflows the container. Adjust the vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com