Solar cell multi-layer anti-reflection grading film and preparation method thereof

A solar cell and preparation technology, which is applied in metal material coating technology, sustainable manufacturing/processing, coating, etc., can solve the problems of low overall reflectivity of the front of the solar cell, large difference in refractive index, and increased light absorption, etc. Achieve excellent passivation, low reflectivity, and increase light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

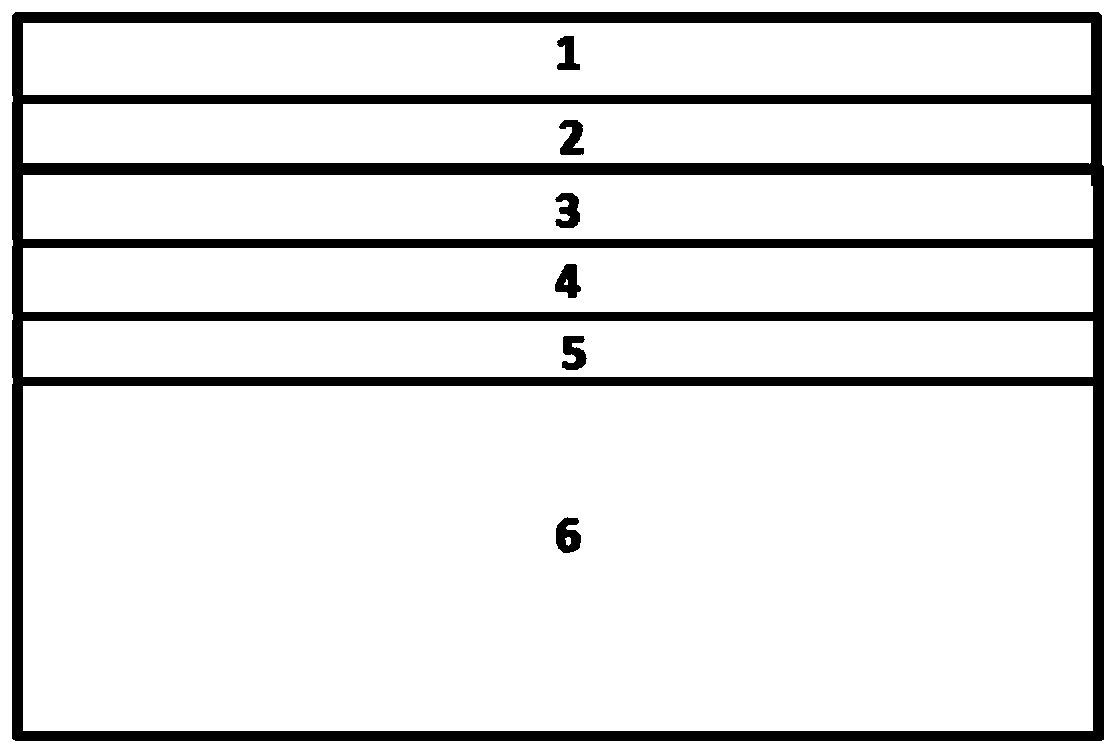

[0041] Such as figure 1 As shown, it is a solar cell multilayer anti-reflection gradient film of the present invention, which includes a first silicon nitride film 5, a second silicon nitride film 4, a first silicon nitride oxide film 3, a second silicon nitride film, Silicon nitride oxide film 2 and silicon oxide film 1, and the refractive index of each film decreases layer by layer from bottom to top. The film thickness of the first silicon nitride film 5 is 12nm, and the refractive index is 2.23; the film thickness of the second silicon nitride film 4 is 45nm, and the refractive index is 2.05; The ratio is 1.93; the film thickness of the second silicon oxynitride film 2 is 6 nm, and the refractive index is 1.68; the film thickness of the silicon oxide film 1 is 5 nm, and the refractive index is 1.41.

[0042] The multilayer anti-reflection gradient film of the solar cell has a thickness of 74nm and a refractive index of 2.09.

[0043] A preparation process for the above-m...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that: the film thickness of the first silicon nitride film 5 is 12nm, and the refractive index is 2.21; the film thickness of the second silicon nitride film 4 is 45nm, and the refractive index is 2.09; A silicon oxynitride film 3 has a thickness of 6 nm and a refractive index of 1.96; a second silicon oxynitride film 2 has a thickness of 6 nm and a refractive index of 1.74; a silicon oxide film 1 has a thickness of 6 nm and a refractive index of 1.45.

[0052] The multilayer anti-reflection gradient film of the solar cell has a thickness of 75nm and a refractive index of 2.08.

[0053] A preparation process for the above-mentioned solar cell multilayer anti-reflection gradient film, specifically comprising the following steps:

[0054] S1. Using tubular plasma deposition equipment to deposit the first silicon nitride film 5 on the front side of the monocrystalline silicon wafer 6 after texturing treatment, the ...

Embodiment 3

[0060] The difference between this embodiment and Embodiment 1 is that: the film thickness of the first silicon nitride film 5 is 12nm, and the refractive index is 2.21; the film thickness of the second silicon nitride film 4 is 45nm, and the refractive index is 2.08; A silicon oxynitride film 3 has a thickness of 6 nm and a refractive index of 1.95; a second silicon oxynitride film 2 has a thickness of 6 nm and a refractive index of 1.76; a silicon oxide film 1 has a thickness of 6 nm and a refractive index of 1.46.

[0061] The multilayer anti-reflection gradient film of the solar cell has a thickness of 75nm and a refractive index of 2.09.

[0062] A preparation process for the above-mentioned solar cell multilayer anti-reflection gradient film, specifically comprising the following steps:

[0063] S1. Using tubular plasma deposition equipment to deposit the first silicon nitride film 5 on the front side of the monocrystalline silicon wafer 6 after texturing treatment, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com