Ink-jet recording head and ink-jet recording apparatus

A technology of inkjet recording and recording elements, which is applied in the direction of measuring devices, measuring devices, instruments, etc., and can solve problems such as difficult clocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

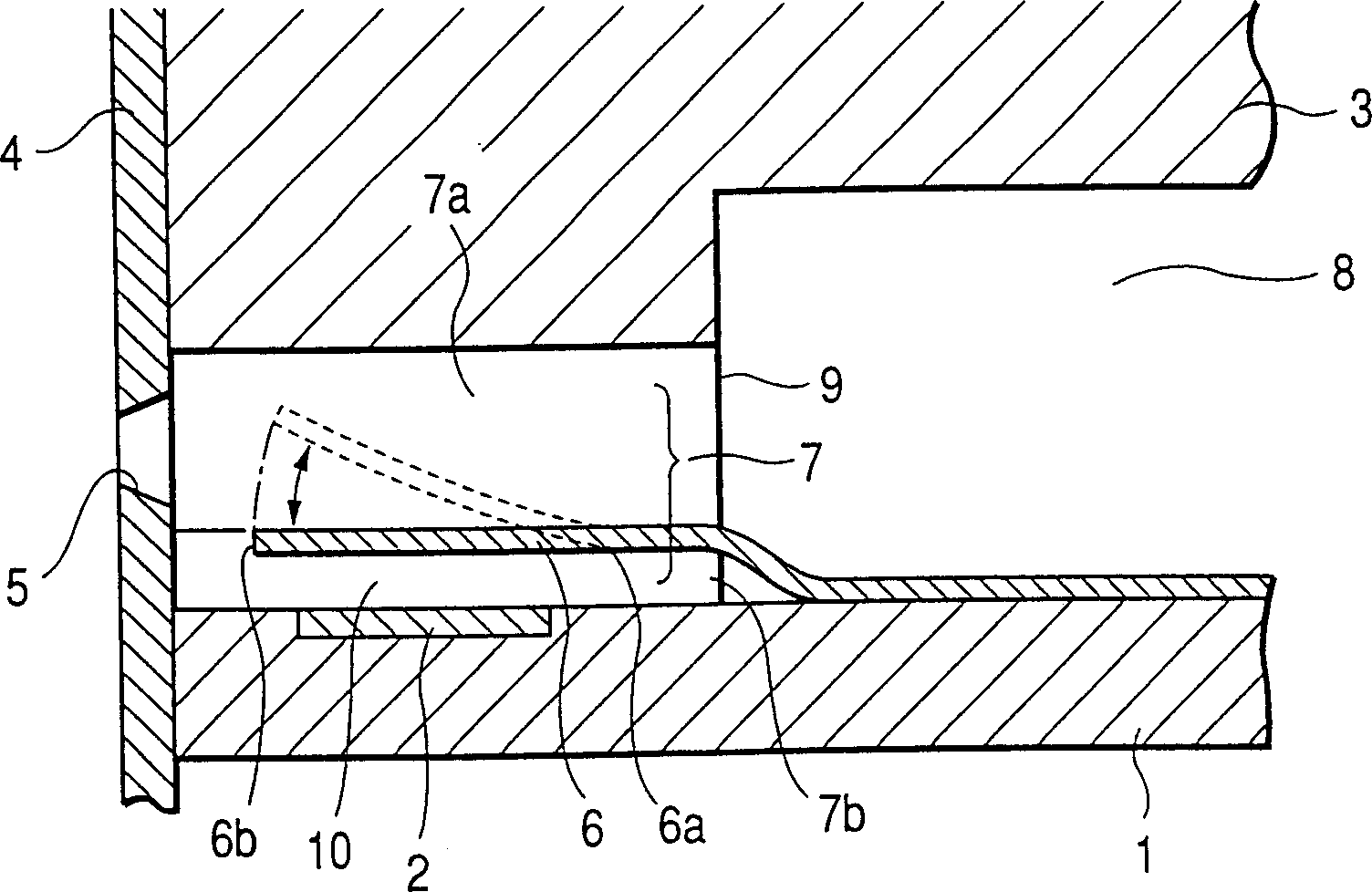

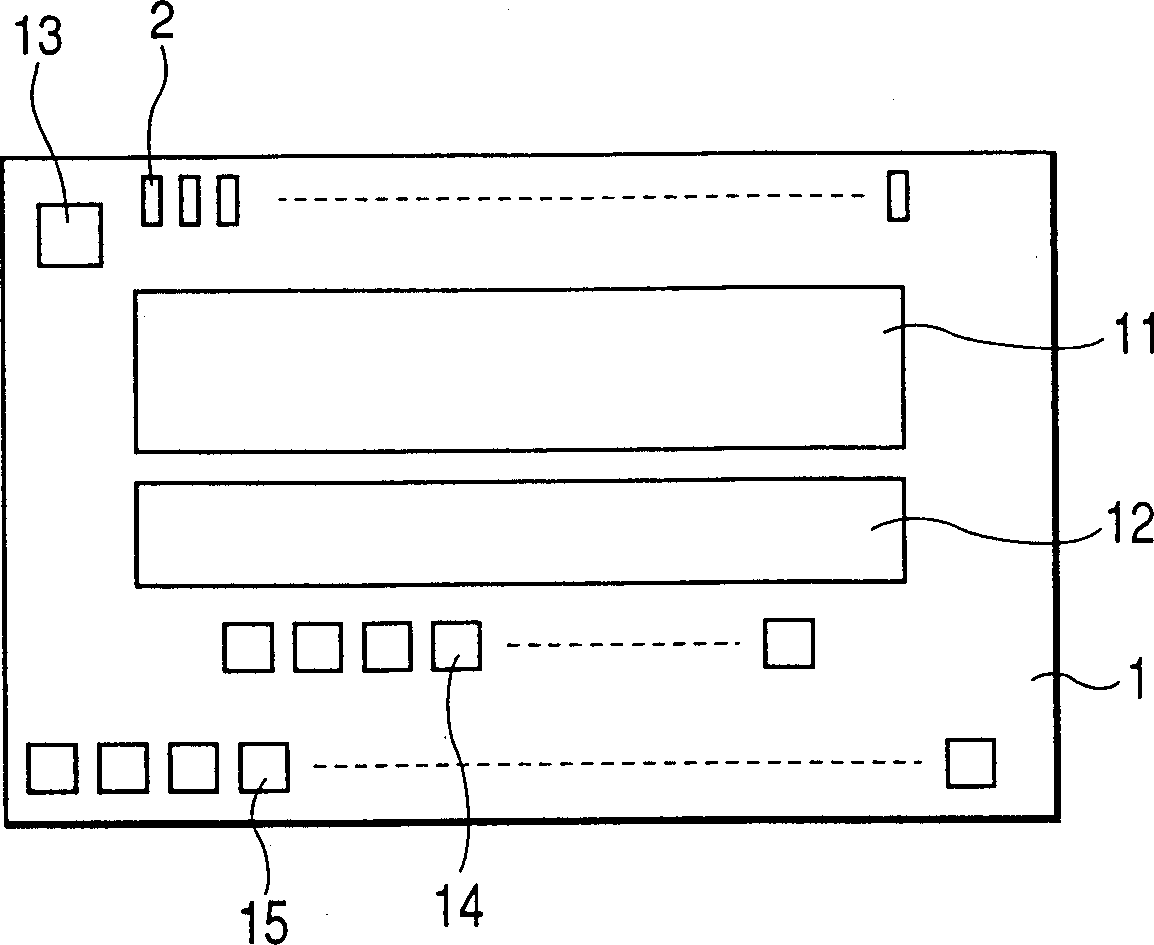

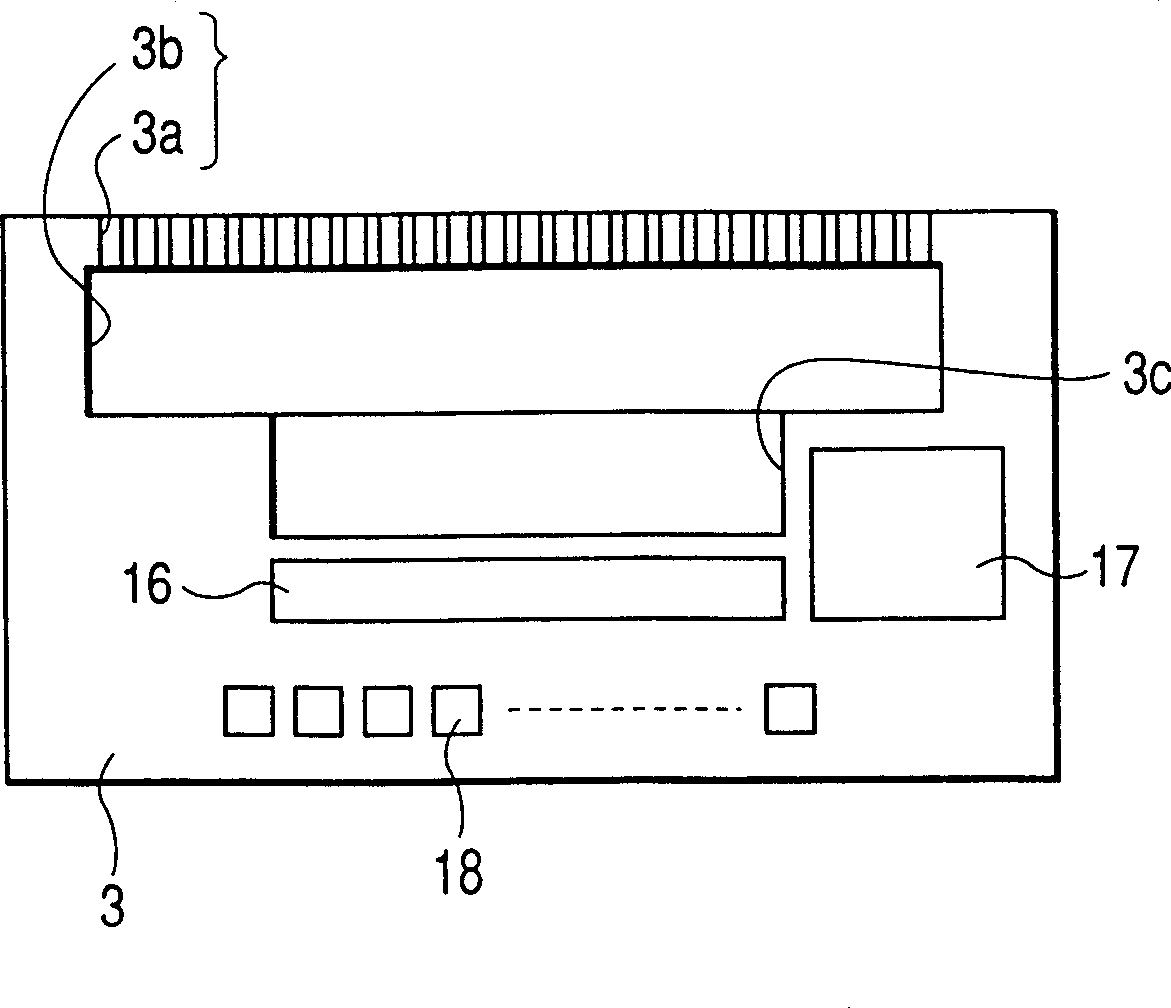

[0056] An ink jet recording head as a first embodiment usable in the present invention will be described below. The head has: a plurality of discharge orifices for discharging ink (liquid); a first substrate and a second substrate that are bonded together to form a plurality of liquid passages and are connected to the respective discharge orifices; A plurality of recording elements in each liquid channel are used to convert electrical energy into liquid discharge energy in the liquid channel; a plurality of functionally different elements or circuits are used to control the driving state of the recording elements. According to the function, these elements or circuits are assigned to a first substrate and a second substrate.

[0057] An example in which a heating element (heater) is used as a recording element will be described below, but a piezoelectric element that discharges ink by a piezoelectric effect may also be used for the recording element. figure 1 is a sectional v...

no. 2 example

[0140] Figure 8 is a signal flow diagram representing a second embodiment of the present invention.

[0141] omitted with Image 6 Description of the same section.

[0142] In this embodiment, in the enabling signal generator, the enabling signal is generated from the high resolution reference signal and the image data transfer signal. In this embodiment, since the activation signal does not need to be supplied from the outside, there can be produced an effect that the number of signal lines can be reduced. again Figure 8 In the above, the data transfer signal is used to obtain the heating pulse information, but the head can be added to include non-volatile memory such as EEPROM, and a structure for controlling the memory can be added. In addition, the high-resolution reference signal input to the activation signal generator does not have to be the same as the high-resolution reference signal input to the driving signal control circuit as long as they are synchronized wi...

no. 3 example

[0144] Figure 9 is a signal flow diagram showing a third embodiment of the present invention.

[0145] omitted with Image 6 Description of the same section.

[0146] In the second embodiment, the start signal is generated from the high-resolution reference signal and the image data transfer signal, however, in this embodiment, the start signal is generated from the reference input signal and the image before being input to the high-resolution reference signal generator Data transfer signal. Since the activation signal may have a small resolution relative to the heating signal, the raw reference input signal may be utilized without going through the high resolution reference signal generator relative to some heater drive control signals. Here, the structure of the enlarged CLK portion for calculating the high-resolution reference signal is disadvantageous when the resolution is reduced than necessary (since the circuit is also enlarged with larger calculated values), and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com