A kind of anti-corrosion coating for high temperature condensate recovery device

A technology of high-temperature condensate and recovery device, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of complex film forming process, complex process, inconvenient construction, etc., achieve simple coating process, improve coating corrosion resistance, improve The effect of anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 20g of epoxy-modified silicone resin FJNH-4, add 10g of mica iron oxide ash, 3g of mica, 2g of talcum powder, and 2g of zirconium dioxide, and stir at high speed with a powerful electric mixer for 15-20 minutes. Add 0.2g of dispersant BYK-142 and 0.2g of defoamer BYK-066N during stirring to obtain component A.

[0022] (2) Weigh 3.5g polyamide T651 curing agent as component B.

[0023] (3) Mix the two components, A and B, and stir them evenly with a stirrer to obtain the coating of the present invention.

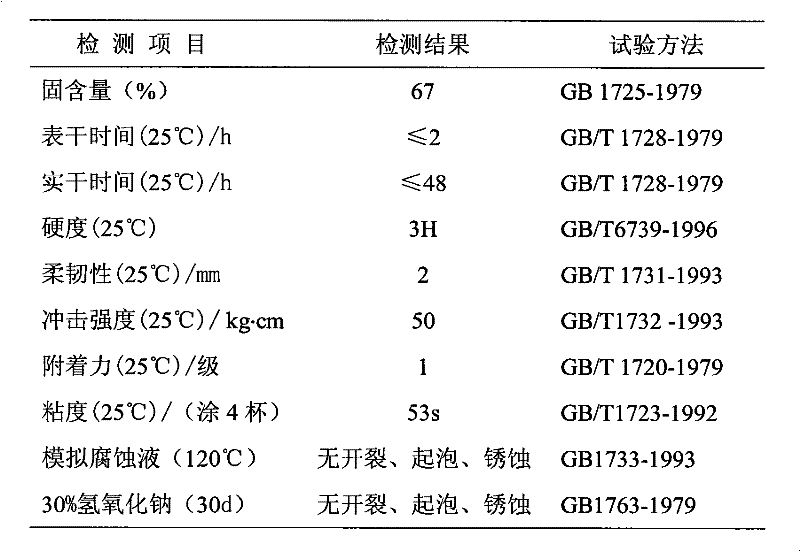

[0024] (4) Apply the paint on the test piece of the steel plate according to the national standard, control the thickness of the coating at about 150 μm, and cure it at room temperature at about 25°C for 48 hours. After hard drying, the physical and mechanical properties and chemical corrosion resistance of the coating are as follows:

[0025]

Embodiment 2

[0027] (1) Weigh 20g of epoxy-modified silicone resin FJNH-4, add 10g of mica iron oxide ash, 3g of mica, 2g of talcum powder, and 3g of zirconium dioxide, and stir at high speed with a powerful electric mixer for 15-20 minutes. Add 0.2g of dispersant BYK-142 and 0.2g of defoamer BYK-066N during stirring to obtain component A.

[0028] (2) Weigh 3.5g polyamide T651 curing agent as component B.

[0029] (3) Mix the two components, A and B, and stir them evenly with a stirrer to obtain the coating of the present invention.

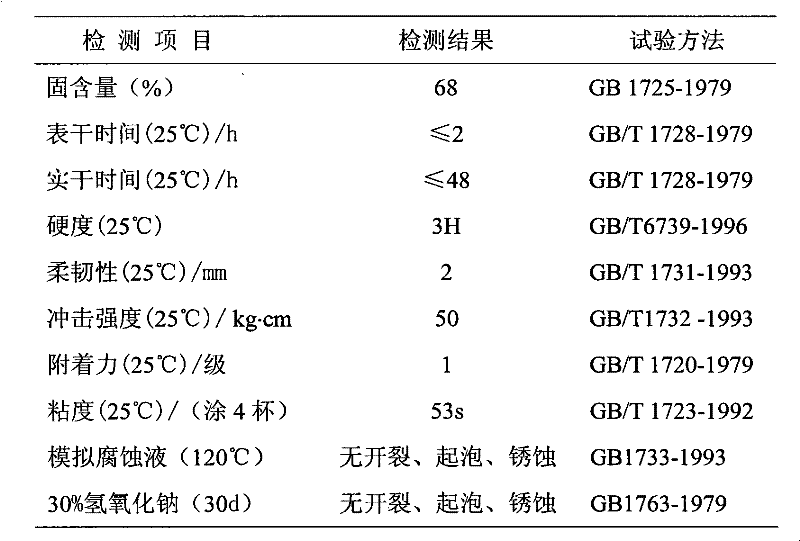

[0030] (4) Apply the paint on the test piece of the steel plate according to the national standard, control the thickness of the coating at about 150 μm, and cure it at room temperature at about 25°C for 48 hours. After hard drying, the physical and mechanical properties and chemical corrosion resistance of the coating are as follows:

[0031]

Embodiment 3

[0033] (1) Weigh 20g of epoxy-modified silicone resin FJNH-4, add 10g of mica iron oxide ash, 3g of mica, 2g of talcum powder, and 4g of zirconium dioxide, and stir for 15-20 minutes at high speed with a powerful electric mixer. Add 0.2g of dispersant BYK-142 and 0.2g of defoamer BYK-066N during stirring to obtain component A.

[0034] (2) Weigh 3.5g polyamide T651 curing agent as component B.

[0035] (3) Mix the two components, A and B, and stir them evenly with a stirrer to obtain the coating of the present invention.

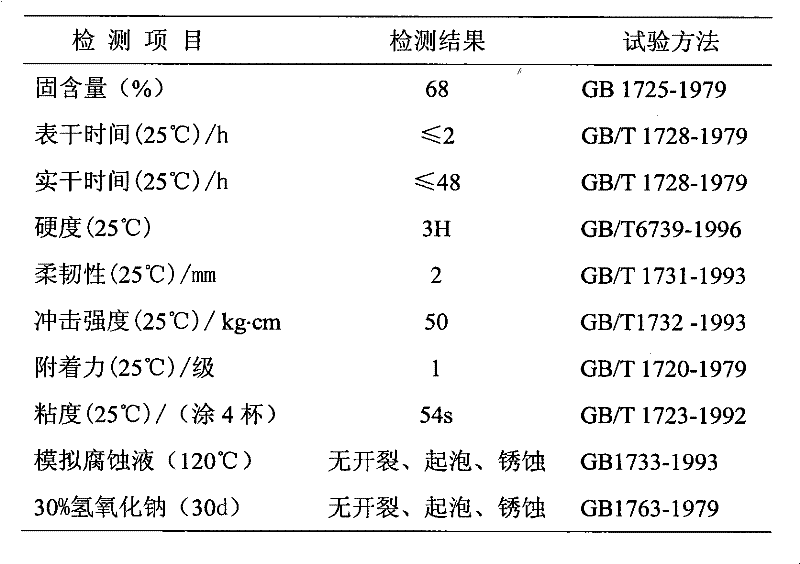

[0036] (4) Apply the paint on the test piece of the steel plate according to the national standard, control the thickness of the coating at about 150 μm, and cure it at room temperature at about 25°C for 48 hours. After hard drying, the physical and mechanical properties and chemical corrosion resistance of the coating are as follows:

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com