Monitoring and controlling method and device for corrosion resistance of heat supply network circulating water system

A circulating water system, monitoring and control technology, applied to chemical instruments and methods, testing water, water pollutants, etc., can solve problems such as carbon steel pipeline corrosion, pipeline and heat exchanger corrosion, and achieve the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

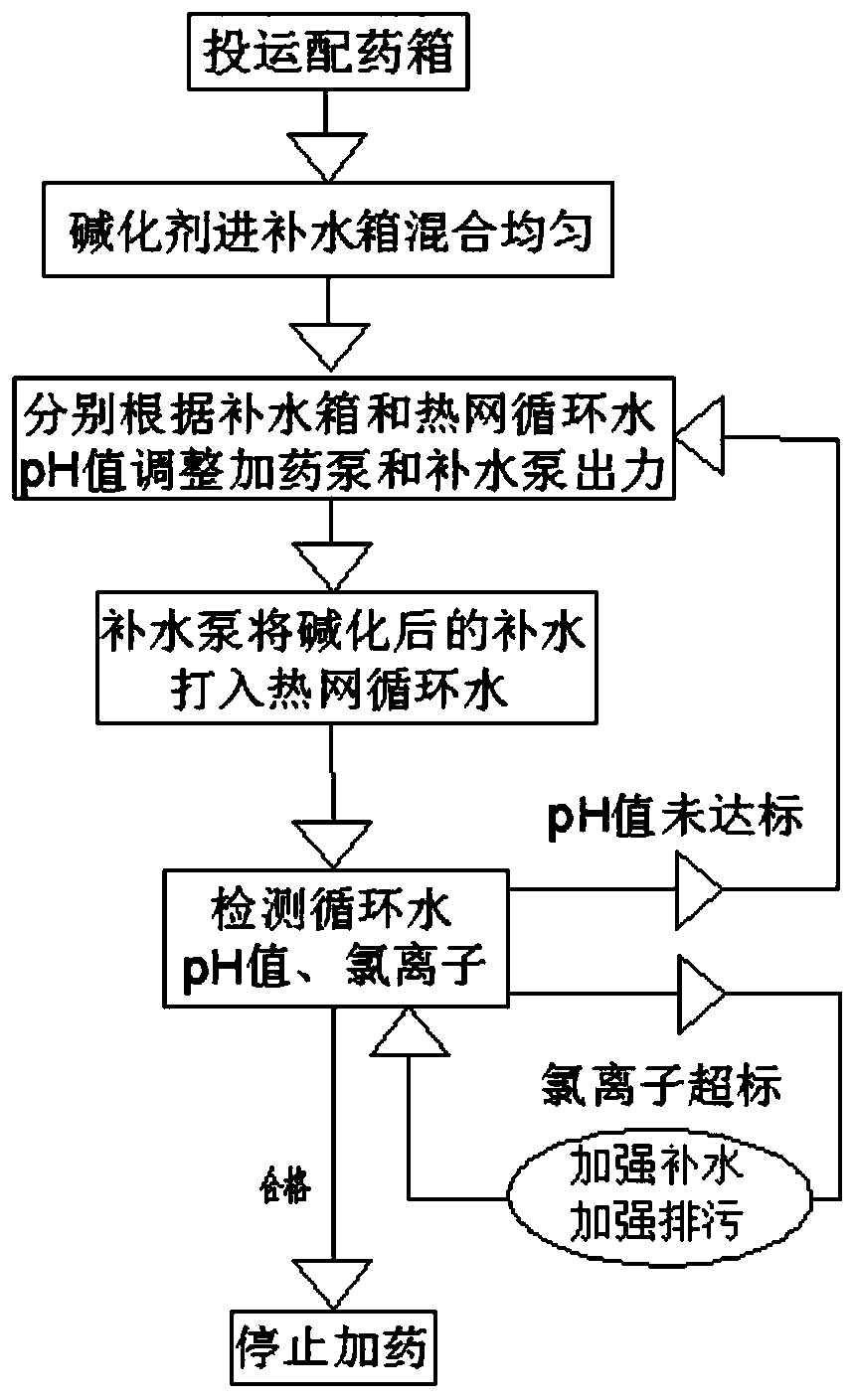

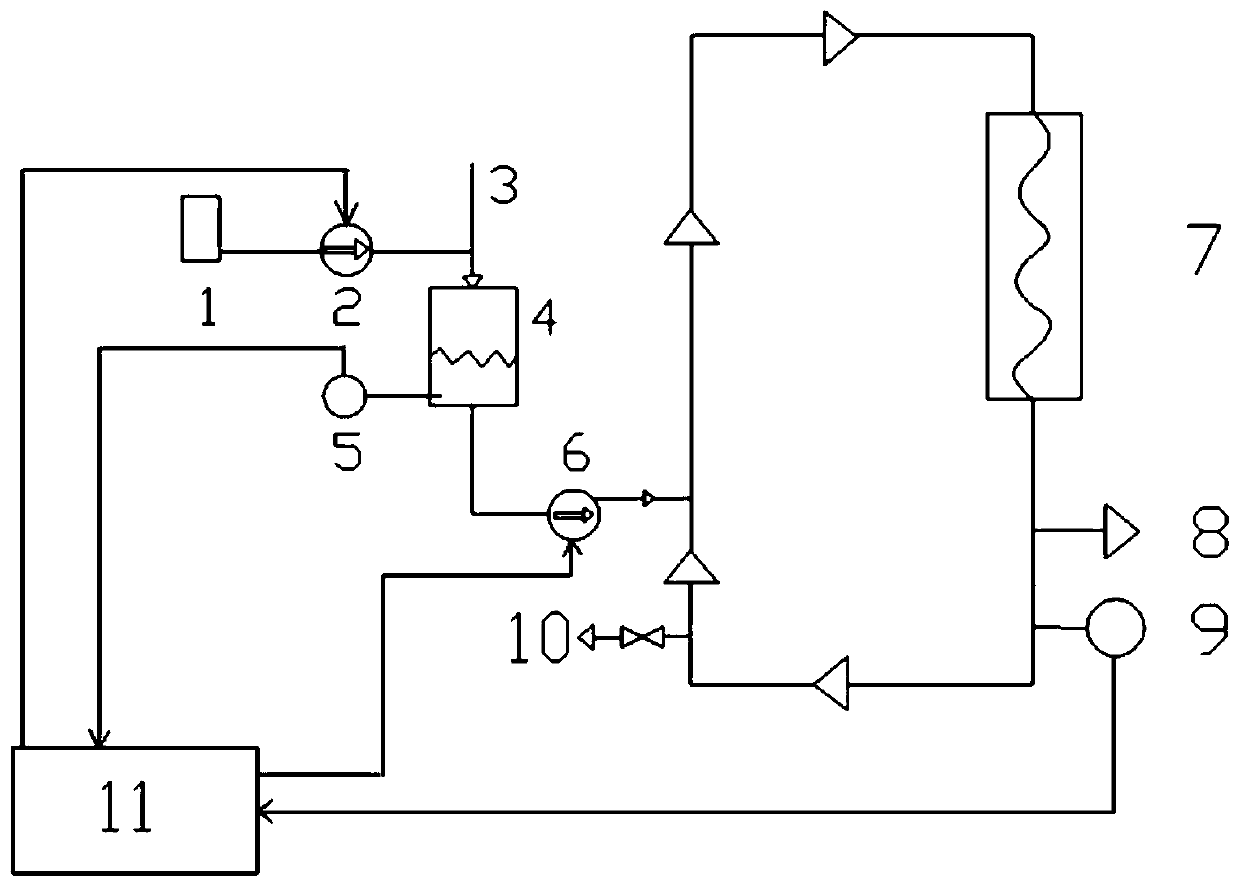

[0030] The present invention is a monitoring and control method and device for anticorrosion of the circulating water system of the heating network. Through the setting of the dosing system and the feedback of the detection system, a sufficient amount of alkalizing agent can be added, and the heating network circulation can be automatically monitored and manually detected in real time. Water quality, feedback adjustment of dosing, water replenishment and sewage discharge to ensure the quality of circulating water in the heating network, effectively prevent the shortened service life and equipment leakage caused by corrosion of the circulating water system in the heating network, and ensure the safety of equipment and the safety of heat used in production and living .

[0031] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com