Magnesium alloy surface calcium series phosphorization solution and formation processing technique thereof

A technology for chemical formation treatment and magnesium alloy, applied in the direction of metal material coating process, etc., can solve the problems of non-compliance with environmental protection requirements, hexavalent chromium toxicity, environmental pollution, etc., and achieve the effects of less environmental pollution, low cost, and simple wastewater treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Prepare magnesium alloy surface calcium system phosphating solution according to the following formula:

[0016] Monocalcium Phosphate 15g

[0017] Phosphoric acid 6ml

[0018] Nitrate 10g

[0019] Polyphosphate 1g

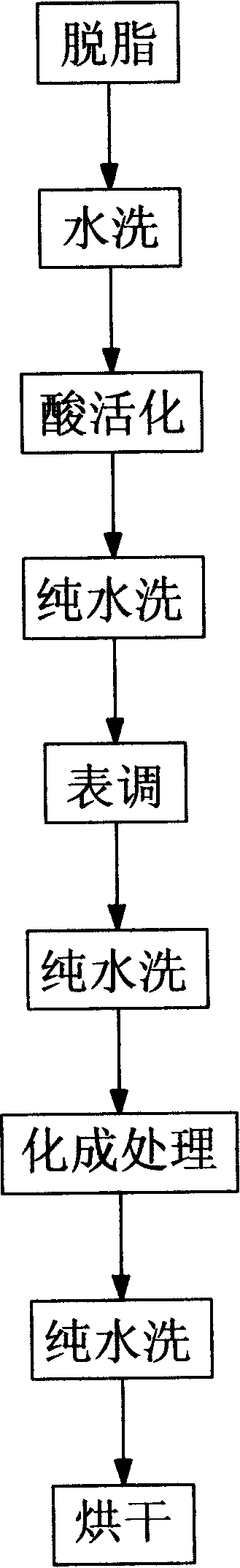

[0020] see figure 1 , which shows the process flow of using the calcium-based phosphating solution of the present invention to chemically treat the surface of a magnesium alloy.

[0021] As shown in the figure, the process flow is: degreasing→water washing→acid activation→pure water washing→surface adjustment→pure water washing→chemical conversion treatment→pure water washing→drying.

[0022] Specifically, the surface of the AZ91D magnesium alloy sample was degreased, washed with water, and then activated with an organic acid selected from acetic acid, oxalic acid, oxalic acid, and benzoic acid. After washing with industrial pure water, use alkaline surface conditioner for surface adjustment, and then carry out chemical conversion treatment after washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com