Corrosion-resistant and high-temperature-resistant anticorrosive powder coating in steel pipeline for oil field water injection well

A technology of oil field water injection and powder coating, which is applied in the direction of powder coating, fireproof coating, epoxy resin coating, etc., can solve the problems of steel pipe corrosion damage, loss of protection, corrosion of anti-corrosion coating, etc., and achieve prolonging service life, smooth surface, Effect of improving surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

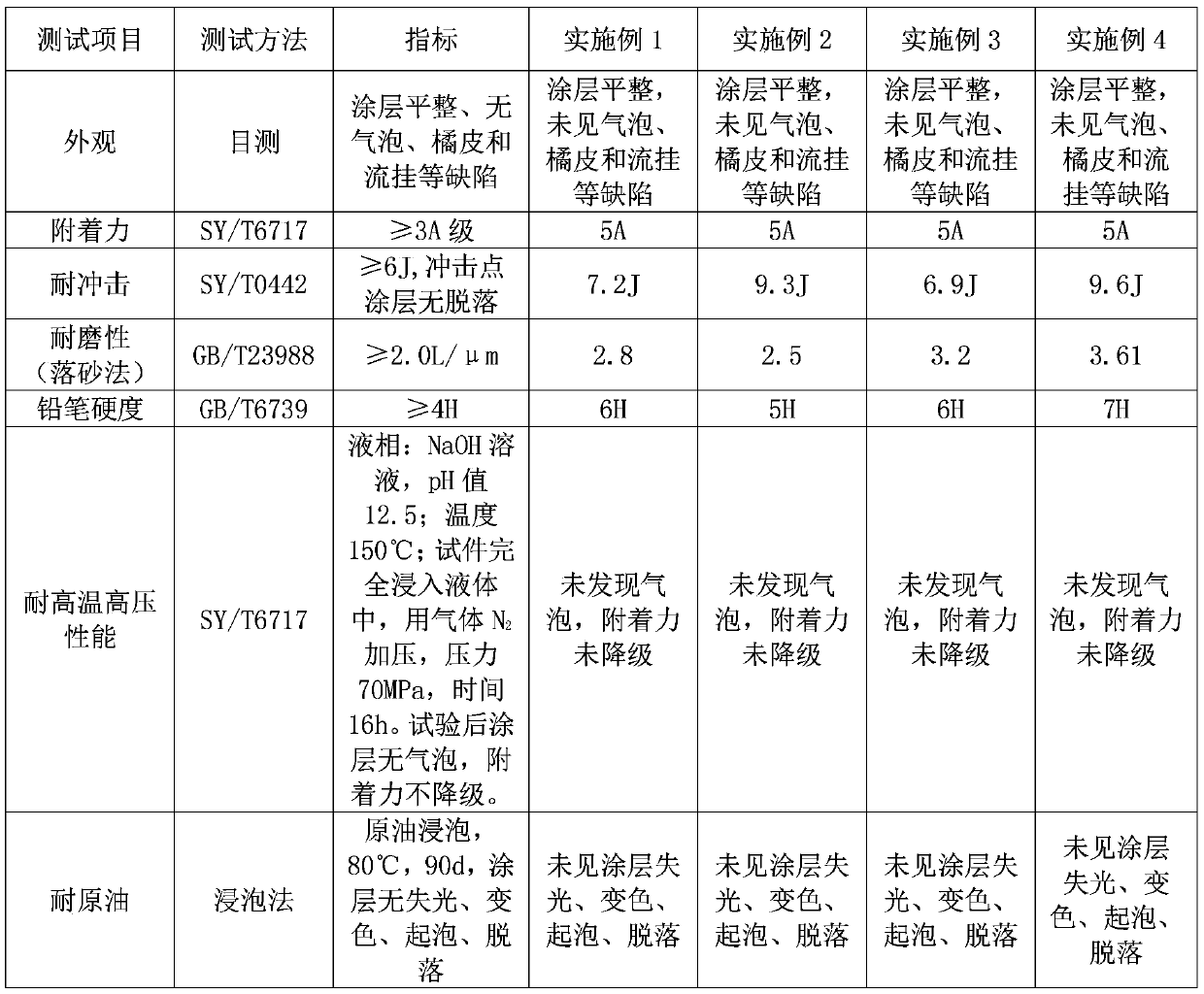

Examples

Embodiment 1

[0030] This embodiment discloses a corrosion-resistant and high-temperature-resistant steel pipeline internal anti-corrosion powder coating for oilfield water injection wells, which includes the following components by weight:

[0031] 40 parts of bisphenol A epoxy resin;

[0032] Alicyclic epoxy resin 20 parts (HP-7200H);

[0033] 20 parts of curing agent (Aradur9690, Amanda9887M curing agent publicly sold on the market are adopted in this embodiment);

[0034] 10 parts of feldspar powder;

[0035] 8 parts of barium sulfate;

[0036] 10 parts of mica powder;

[0037] 35 parts of high temperature and corrosion resistant materials;

[0038] 1 part of acrylate copolymer leveling agent (BYK-3950P);

[0039] 1 part of curing accelerator (adopting CUREZOL2MZ-A, CUREZOLC11Z-A publicly available on the market in this embodiment);

[0040] 1 part of defoamer (adopt BYK961 publicly sold on the market in this embodiment);

Embodiment 2

[0047] This embodiment discloses a corrosion-resistant and high-temperature-resistant steel pipeline internal anti-corrosion powder coating for oilfield water injection wells, which includes the following components by weight:

[0048] 50 parts of bisphenol A epoxy resin;

[0049] Alicyclic epoxy resin 25 parts (HP-7200);

[0050] 25 parts of curing agent (adopt DEH90, Amanda969T02 (SD) publicly available on the market in this embodiment);

[0051] 15 parts of feldspar powder;

[0052] 5 parts of barium sulfate;

[0053] 10 parts of mica powder;

[0054] 25 parts of high temperature and corrosion resistant materials;

[0055] 1.2 parts of acrylic ester copolymer leveling agent (adopt BYK-3950P publicly sold on the market in this embodiment);

[0056] 1.5 parts of curing accelerator (adopting CUREZOL2MZ-A, CUREZOLC11Z-A publicly available on the market in this embodiment);

[0057] 1 part of defoamer (adopt BYK961 publicly sold on the market in this embodiment);

[0058]...

Embodiment 3

[0063] This embodiment discloses a corrosion-resistant and high-temperature-resistant steel pipeline internal anti-corrosion powder coating for oilfield water injection wells, which includes the following components by weight:

[0064] 50 parts of bisphenol A epoxy resin;

[0065] Alicyclic epoxy resin 30 parts (NC-7000L);

[0066] 30 parts of curing agent (Amanda9698, DEH85);

[0067] 20 parts of feldspar powder;

[0068] 10 parts of barium sulfate;

[0069] 25 parts of mica powder;

[0070] 45 parts of high temperature and corrosion resistant materials;

[0071] 2.5 parts of acrylate copolymer leveling agent (Lida Chemical LD-606A);

[0072] 2.5 parts of curing accelerator (CUREZOL2PZ, CUREZOL C11Z-A);

[0073] 2 parts of defoamer (BYK961);

[0074] 3 parts of wetting agent (BYK-3950P);

[0075] 3 parts of paint.

[0076]Among them, the high temperature and corrosion resistant material is: a mixture of titanium diboride, titanium nitride and graphene powder, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com