Spray polyurea elastomer and preparation method thereof

A technology of polyurea elastomer and volume ratio, applied in the direction of polyurea/polyurethane coatings, coatings, etc., to achieve the effects of low friction coefficient, reduced conveying resistance, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

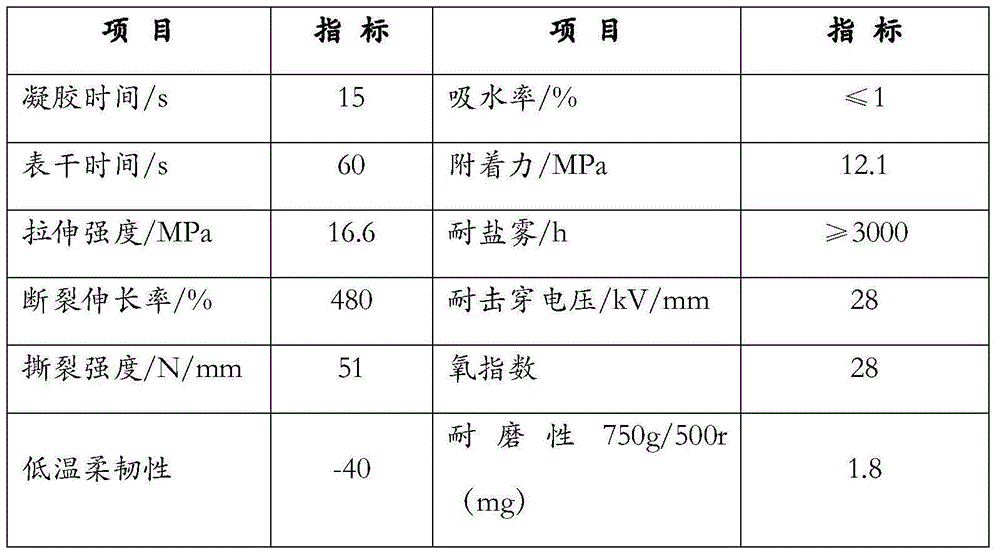

Embodiment 1

[0041] A preparation method for spraying polyurea elastomer, comprising:

[0042] (1) Preparation of component A:

[0043] Add 100 parts of polyoxypropylene diol N210 and 50 parts of 2,2,3,3-tetrafluoro-1,4-butanediol into the reactor, dehydrate at 120°C for 2 hours under a vacuum of 0.09MPa, and then lower the temperature Add dropwise to 313 parts of toluene diisocyanate reaction kettle at 50°C, slowly raise the temperature to 90°C, keep the temperature for 2 hours, cool down after defoaming, and obtain component A of isocyanate prepolymer with -NCO content of 12%;

[0044] (2) Preparation of component B:

[0045] Pour 30 parts of amino-terminated polyether D2000, 30 parts of dimethylthiotoluenediamine, 0.5 part of fumed silica, 0.1 part of TegoDispers610 and 0.5 part of TegoFoamexN into the reaction kettle, raise the temperature to 60°C, stir for 30min, and rotate at 600r / min, then add 1.0 parts of color paste and continue to stir for 30 minutes to obtain component B;

...

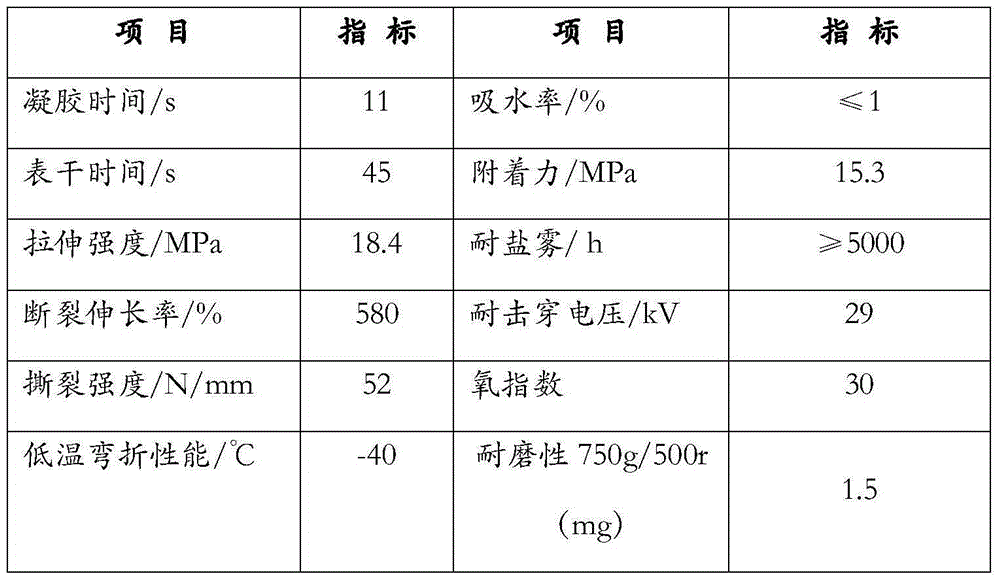

Embodiment 2

[0051] A preparation method for spraying polyurea elastomer, comprising:

[0052] (2) Preparation of component A:

[0053] Add 50 parts of 1H,1H,5H,5H-perfluoro-1,5-pentanediol and 50 parts of polytetrahydrofuran-oxypropylene copolymerized glycol into the reaction kettle, dehydrate at 125°C and 0.09MPa vacuum for 2.5h , then drop the temperature to 50°C and drop it into a reaction kettle of 97.5 parts of isophorone diisocyanate, slowly raise the temperature to 85°C, keep the temperature for 2.5 hours, cool down after defoaming, and obtain an isocyanate prepolymer with a -NCO content of 17%. A component;

[0054] (2) Preparation of component B:

[0055]Pour 40 parts of amino-terminated polyether T5000, a mixture of 36 parts of dimethylthiotoluenediamine and diethyltoluenediamine, 0.8 parts of fumed silica, 0.3 parts of TegoDispers630 and 0.7 parts of Airex930 into the reaction kettle, and heat up to Stir at 70°C for 36 minutes at a speed of 700r / min, then add 3.0 parts of co...

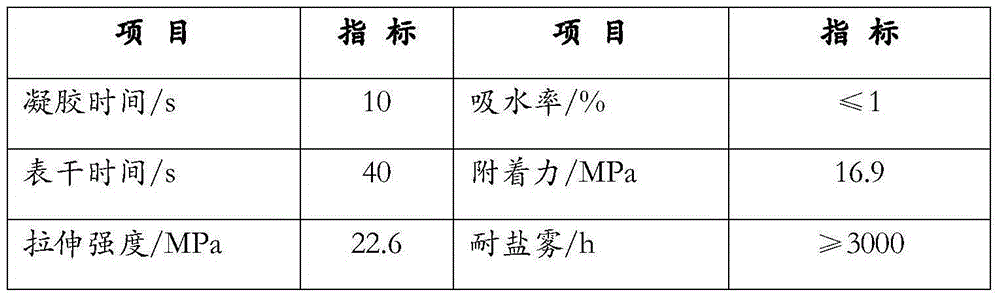

Embodiment 3

[0061] A preparation method for spraying polyurea elastomer, comprising:

[0062] (1) Preparation of component A:

[0063] Add 100 parts of polyoxypropylene diol N204 and 50 parts of 1H,1H,10H,10H-perfluoro-1,10-decanediol into the reaction kettle, dehydrate at 130°C and 0.09MPa vacuum for 3 hours, then lower the temperature Add dropwise to 249 parts of diphenylmethane diisocyanate and 4,4'-dicyclohexylmethane diisocyanate reaction kettle at 50°C, slowly raise the temperature to 80°C, keep the temperature for 3 hours, and cool down after defoaming to obtain the -NCO content 20% isocyanate prepolymer A component;

[0064] (2) Preparation of component B:

[0065] Pour 50 parts of amino-terminated polyether D2000, 45 parts of N,N'-dialkylmethyldiamine, 1 part of fumed silica, 0.5 part of TegoDispers610, 0.5 part of Airex900 and 0.5 part of Airex950 into the reaction kettle, and heat up to Stir at 80°C for 45 minutes at a speed of 800r / min, then add 5.0 parts of color paste and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com