Advanced wastewater treatment apparatus using SBR system

A technology of sequencing batch reactor and treatment device, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. The final treatment and other issues can save the setting area, save the setting cost, and improve the processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, a device for advanced sewage treatment using a sequencing batch reactor process according to a preferred embodiment will be described in detail with reference to the accompanying drawings. The same reference numerals are used for the same structures, and redundant descriptions and detailed descriptions of well-known functions and structures that may unnecessarily obscure the gist of the invention are omitted. Embodiments of the invention are provided to enable those skilled in the art to understand the present invention more completely. Therefore, the shape and size of each element in the drawings may be exaggerated for clearer illustration.

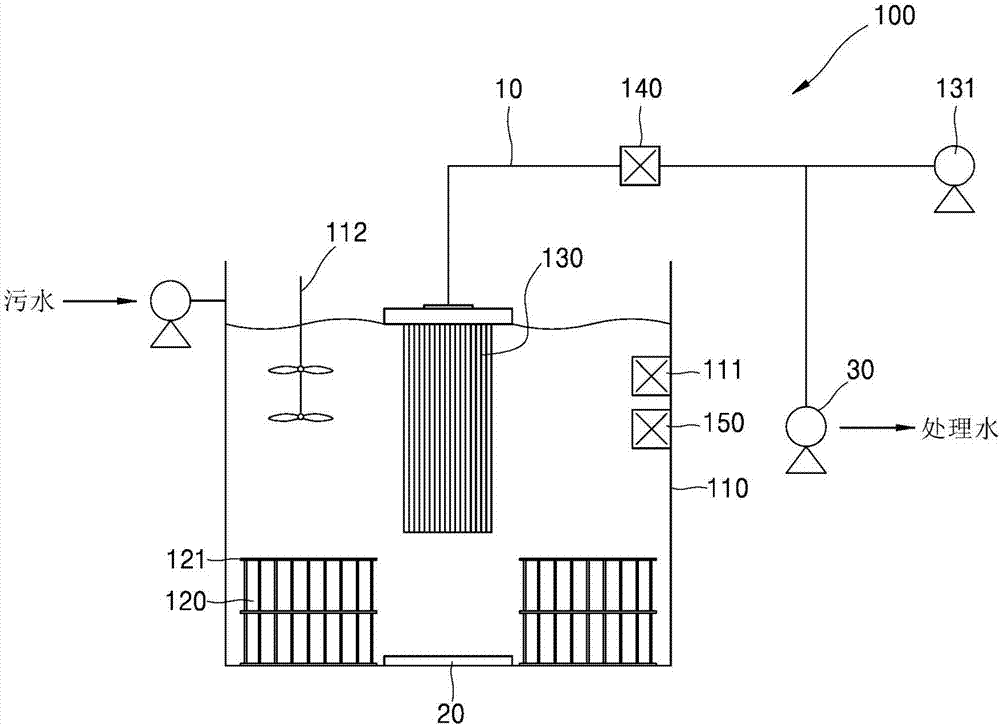

[0035] figure 1 It is a structural diagram of a high-level sewage treatment device using a sequencing batch reactor process according to an embodiment of the present invention.

[0036] Such as figure 1 As shown, the advanced sewage treatment device 100 using the sequencing batch reactor process includes a sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com