Method for catalytic wet oxidation treatment of high concentration cymoxanil wastewater

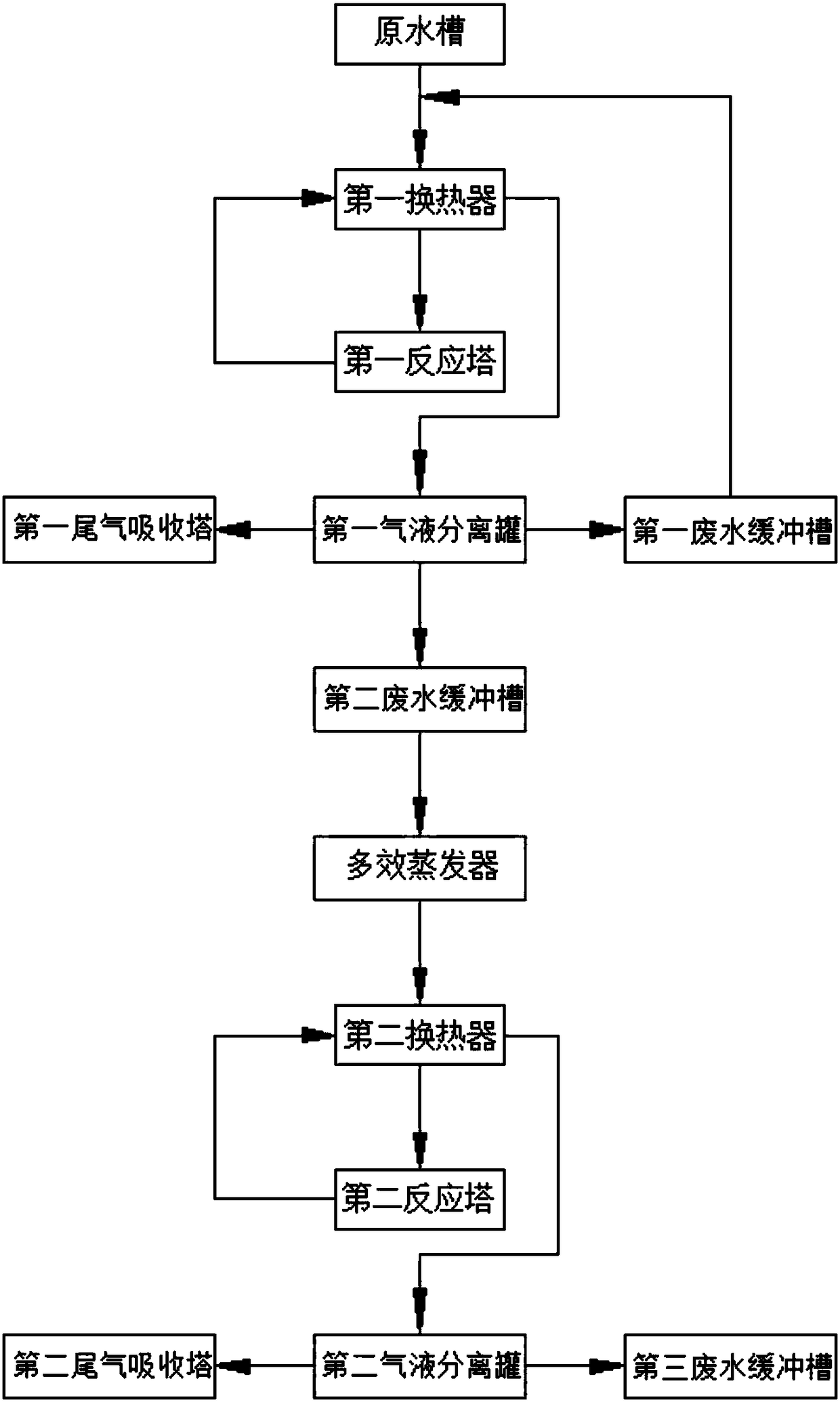

A technology for catalytic wet oxidation and wet oxidation, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water treatment, etc. The processing effect can be guaranteed, the floor space is small, and the degree of automation is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

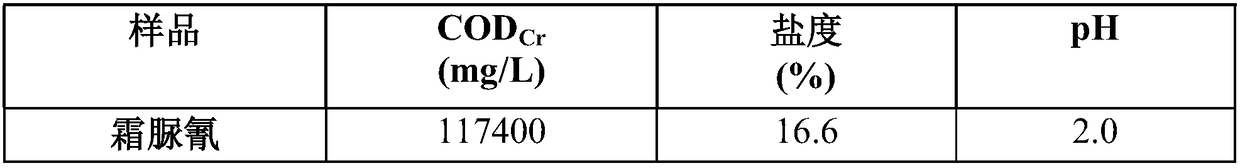

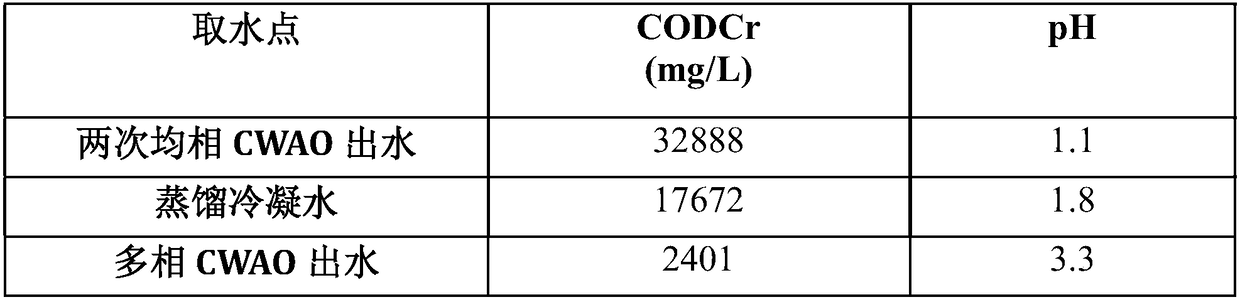

[0016] The 4t / h cymoxanil mother liquor passes twice through the first reaction tower (Φ800mm﹡10000mm) filled with 4.5t inert packing (V (zirconium dioxide): V (sponge titanium) = 4:1) for catalytic wet oxidation treatment , the reaction conditions are as follows: adjust the raw water to pH=2.0 with concentrated sulfuric acid and add 1000mg / L manganese nitrate solution (calculated as manganese ions), reaction temperature=270°C, reaction pressure=7.0MPa, LHSV=1h -1 . The water from the two CWAO reactions is distilled under the condition of a vacuum of 0.085MPa to keep the water sample slightly boiling to evaporate the condensed water, and the condensed water enters the heterogeneous catalytic wet oxidation reaction tower (the second reaction tower) (Φ800mm﹡9000mm) for treatment, in which the tower There are 4t catalysts inside (zirconium dioxide loading is 3wt.% ruthenium + 1wt.% palladium), at reaction temperature = 240°C, reaction pressure = 6.0MPa, LHSV = 1h -1 Under the co...

Embodiment 2

[0022] The 4t / h cymoxanil mother liquor passed twice through the first reaction tower (Φ800mm*10000mm) filled with 4.5t inert packing (V (zirconium dioxide): V (titanium sponge) = 4:1) for catalytic wet oxidation treatment, The reaction conditions are as follows: Use concentrated sulfuric acid to adjust the pH of the raw water to 4.0, then add a homogeneous catalyst copper sulfate solution 1000 mg / L (calculated as copper ions), reaction temperature = 200 ° C, reaction pressure = 4.0 MPa, LHSV = 1h -1 . The water from the two CWAO reactions is distilled under the condition of a vacuum of 0.085MPa to keep the water sample slightly boiling to evaporate the condensed water, and the condensed water enters the heterogeneous catalytic wet oxidation reaction tower (the second reaction tower) (Φ800mm﹡9000mm) for treatment, in which the tower Equivalent volumes of two catalysts are installed in total 4t (3wt.% ruthenium + 1wt.% palladium loaded on zirconia and 1wt.% lanthanum + 2wt.% pa...

Embodiment 3

[0028] The 4t / h cymoxanil mother liquor passed twice through the first reaction tower (Φ800mm*10000mm) filled with 4.5t inert packing (V (zirconium dioxide): V (titanium sponge) = 4:1) for catalytic wet oxidation treatment, The reaction conditions are as follows: add 1000 mg / L of homogeneous catalyst ferric nitrate (calculated as iron ions) to the raw water, reaction temperature = 250°C, reaction pressure = 7.0MPa, LHSV = 1h -1 . The water from the two CWAO reactions is distilled under the condition of a vacuum of 0.085MPa to keep the water sample slightly boiling to evaporate the condensed water, and the condensed water enters the heterogeneous catalytic wet oxidation reaction tower (the second reaction tower) (Φ800mm﹡9000mm) for treatment, in which the tower Equivalent volumes of two catalysts are housed in a total of 4t (3%wt. ruthenium+1wt.% palladium loaded on zirconia and 1wt.‰ platinum+2wt.% rhodium loaded on titania), at reaction temperature=240°C, reaction pressure=6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com