Power plant desulfurization waste water membrane concentrating process and equipment

A technology of desulfurization wastewater and membrane method, which is applied in the direction of general water supply saving, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high treatment cost, serious pollution of reverse osmosis membrane, and utilization of non-reverse osmosis produced water, etc., to achieve The effects of less acid addition, reduced treatment water volume, and low requirements for influent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

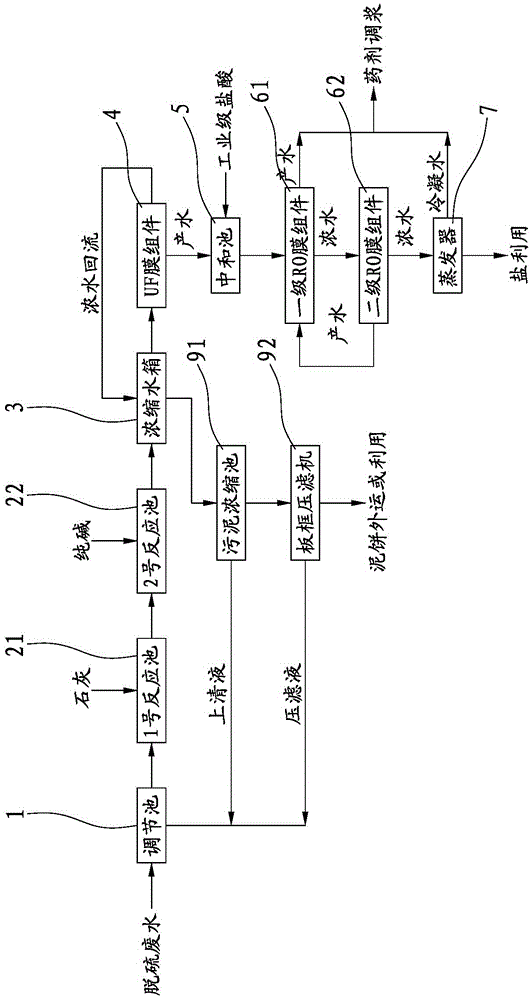

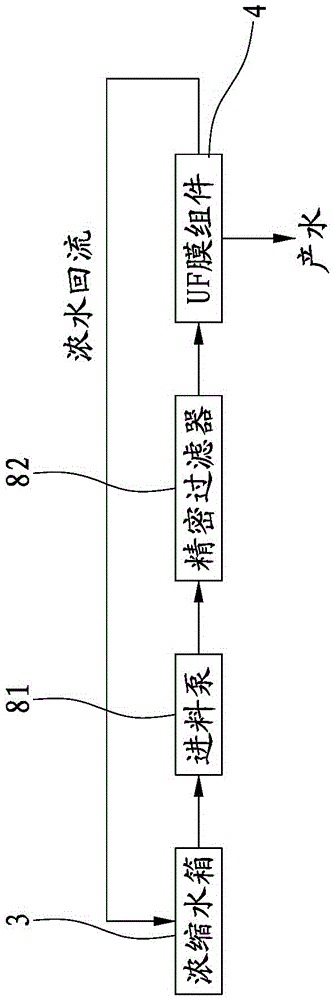

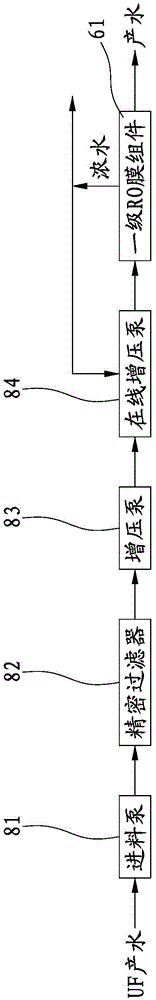

[0049] refer to Figure 1 to Figure 3 As shown, a kind of power plant desulfurization wastewater membrane concentration process disclosed by the present invention comprises the following steps:

[0050] 1. After the desulfurization wastewater is adjusted in the adjustment pool 1 to adjust the water volume and water quality, it will react with the lime with a mass concentration of 1.8-2.3% in the No. 1 reaction pool 21 and continuously stir for 10-20 minutes, and then enter the No. 2 reaction pool 21 in the state of coagulation liquid and mix with it. The soda ash with a mass concentration of 2.0-2.5% is continuously stirred and reacted for 10-20min, and then enters the concentrated water tank 3 in the state of coagulated liquid, and the coagulated liquid is continuously stirred, and the mass concentration of the coagulated liquid in the conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com