High-concentration pickle wastewater treatment process

A technology for wastewater treatment and high concentration, which is used in food industry wastewater treatment, water/sewage treatment, water treatment parameter control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

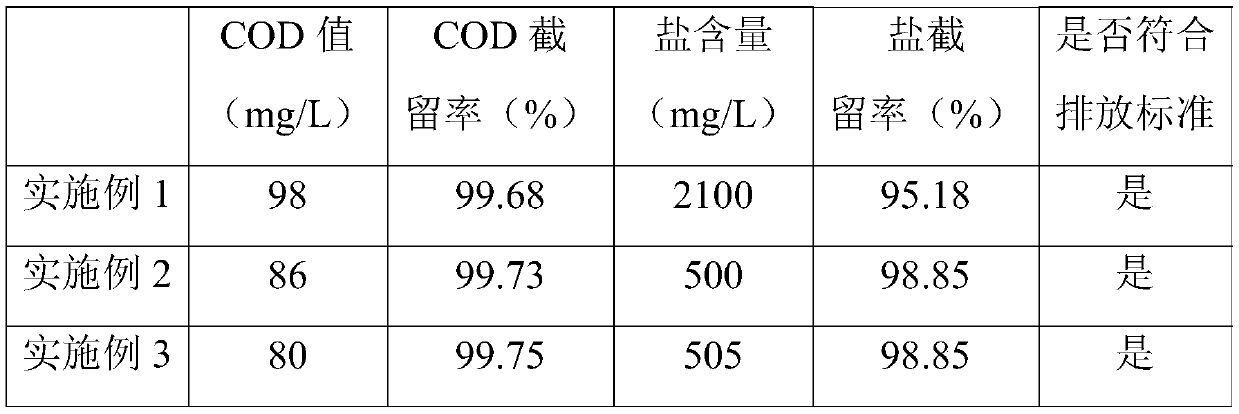

Embodiment 1

[0026] A high-concentration kimchi wastewater treatment process, comprising the following steps:

[0027] (1) Grille adjustment: remove a large amount of suspended solids in the kimchi wastewater through grid treatment, and then adjust the water quality and quantity in the adjustment tank;

[0028] (2) PH adjustment treatment: the pH of the raw water of kimchi wastewater is 5, adjust the pH of the wastewater to alkaline, and precipitate a small amount of heavy metals (if any) and colloidal substances, so that the wastewater becomes clear and transparent from turbidity, which is conducive to subsequent electrodialysis treatment;

[0029] (3) Electrodialysis treatment: Use electrodialysis to carry out sodium chloride salt concentration and COD separation to pickle wastewater, and separate high-concentration COD fresh water and high sodium chloride salt concentrated water to obtain salt solutions with a salt content of 15% respectively and a fresh water solution with a salt conte...

Embodiment 2

[0036] In the case of a large amount of water and a low COD concentration, low-temperature rising MVR can be used instead of electrodialysis. At this time, the high-concentration kimchi wastewater treatment process specifically includes the following steps:

[0037] (1) Grille adjustment: remove a large amount of suspended solids in the kimchi wastewater through grid treatment, and then adjust the water quality and quantity in the adjustment tank;

[0038] (2) PH adjustment treatment: the pH of the raw water of kimchi wastewater is 5, adjust the pH of the wastewater to alkaline, and precipitate a small amount of heavy metals (if any) and colloidal substances, so that the wastewater becomes clear and transparent from turbidity, which is conducive to subsequent electrodialysis treatment;

[0039] (3) MVR treatment: the product obtained in step (2) is pumped into the MVR at 75°C and -0.04MPa, and then the circulating steam in the MVR passes through the steam compressor and the tem...

Embodiment 3

[0045] In the case of large water volume and high COD concentration, low-temperature rising MVR can be used instead of electrodialysis. At this time, the high-concentration kimchi wastewater treatment process specifically includes the following steps:

[0046] (1) Grille adjustment: remove a large amount of suspended solids in the kimchi wastewater through grid treatment, and then adjust the water quality and quantity in the adjustment tank;

[0047] (2) PH adjustment treatment: the pH of the raw water of kimchi wastewater is 5, adjust the pH of the wastewater to alkaline, and precipitate a small amount of heavy metals (if any) and colloidal substances, so that the wastewater becomes clear and transparent from turbidity, which is conducive to subsequent electrodialysis treatment;

[0048] (3) MVR treatment: the product obtained in step (2) is pumped into the MVR at 75°C and -0.04MPa, and then the circulating steam in the MVR passes through the steam compressor and the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com