Desulfurization wastewater treatment process and desulfurization wastewater treatment system

A desulfurization wastewater treatment method technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of high cost of chemicals, complicated operation, long process flow, etc., to achieve energy saving, The effect of reducing the amount of dosing and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0070] According to one embodiment, the pH of the desulfurization wastewater is 4-6.5, the TDS value is 20000-40000 mg / L, the conductivity is 20-35 mS / cm, the calcium ion content is 400-6000 mg / L, and the magnesium ion content is 500 mg / L. -5000mg / L, the sodium ion content is 200-5000mg / L, the chloride ion content is 5000-20000mg / L, the sulfate ion content is 500-15000mg / L, the turbidity is 4000-15000NTU, and the alkalinity is 0.2-50mg / L L, the content of ammonia nitrogen is 10-200mg / L.

[0071] In the treatment method of the present invention, in step (1), the acid is preferably sulfuric acid, and the pH of the neutral softened and clarified effluent is 6-8, more preferably 7-8. In this step, sulfuric acid is added to the softened and clarified water to adjust the pH to neutral, and the added sulfate ions will react with calcium ions in the water to form a small amount of calcium sulfate crystals, which is beneficial to the subsequent reaction in the normal temperature crysta...

Embodiment 1

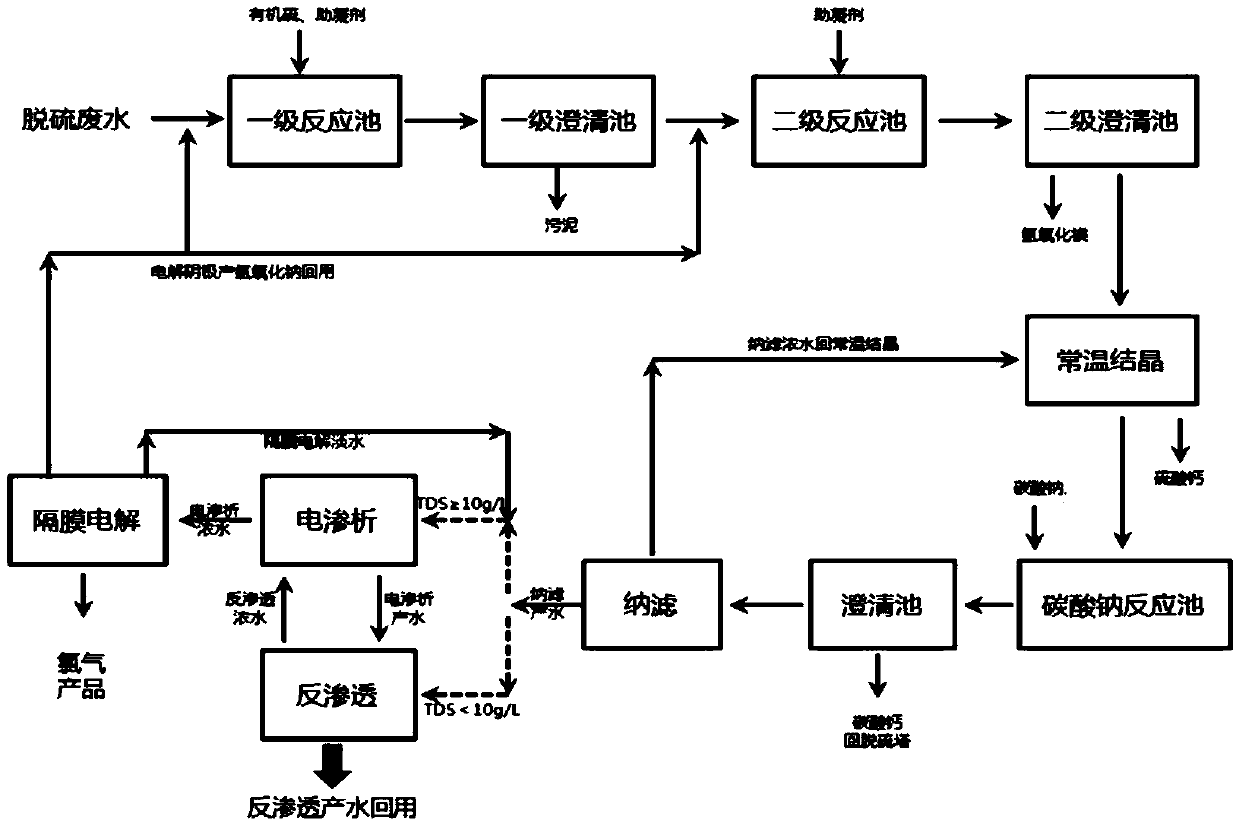

[0136] This embodiment combines figure 1 To illustrate the treatment method of desulfurization wastewater.

[0137] (1) In the primary neutralization reaction tank, add the sodium hydroxide aqueous solution obtained in step (6) to the desulfurization wastewater of the 20t / h power plant to react, adjust the pH of the wastewater to 7.8, and add 20mg / L organic sulfur TMT-15 , 10mg / L flocculant and 5mg / L coagulant, reacted for 60min, and the resulting reaction product was transported to the primary clarifier and settled for 120min to obtain the primary clarified effluent;

[0138] Send the primary clarified effluent to the secondary neutralization reaction tank, continue to add the aqueous sodium hydroxide solution obtained in step (6) therein, adjust the pH of the effluent to be 11.5, and add 5mg / L coagulant aid, react for 70min, and obtain The reaction product was transported to the secondary clarifier and settled for 120 minutes to obtain the magnesium hydroxide product (purit...

Embodiment 2

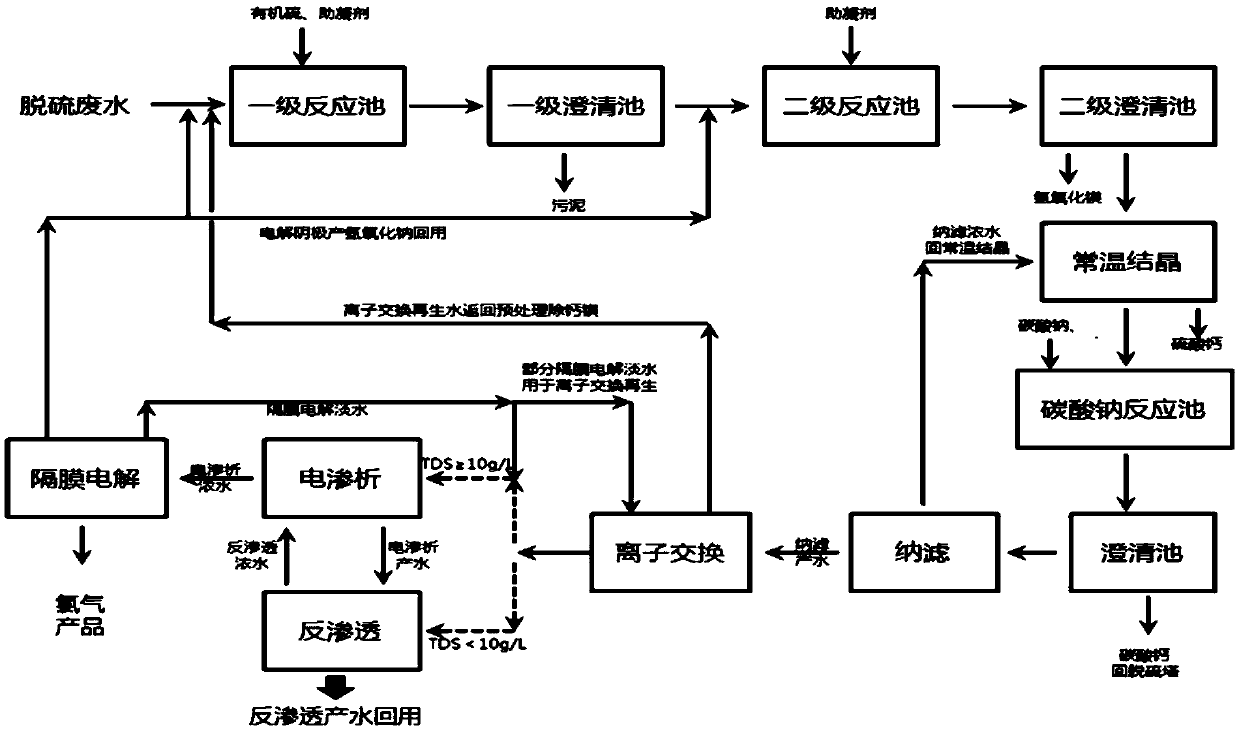

[0151] This embodiment combines figure 2 To illustrate the treatment method of desulfurization wastewater.

[0152] (1) In the primary neutralization reaction tank, add the sodium hydroxide aqueous solution obtained in step (6) to the desulfurization wastewater of the 20t / h power plant to react, adjust the pH of the wastewater to 7.2, and add 30mg / L organic sulfur TMT-15 , 8mg / L flocculant and 5mg / L coagulant, reacted for 60min, and the reaction product obtained was transported to the primary clarification tank and settled for 130min to obtain the primary clarified effluent;

[0153] Send the primary clarified effluent to the secondary neutralization reaction tank, continue to add the aqueous sodium hydroxide solution obtained in step (6) therein, adjust the pH of the effluent to be 11.6, and add 5mg / L coagulant aid, react for 60min, and obtain The reaction product was transported to the second clarifier and settled for 120 minutes to obtain a magnesium hydroxide product (98...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com