Coking wastewater advanced treatment system and treatment method thereof

A technology for advanced treatment and coking wastewater, applied in natural water treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of poor system operation stability, large-scale evaporation system, and low utilization rate of resources. Achieve the effects of reducing the amount of evaporated water, ensuring safe and stable operation, and reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

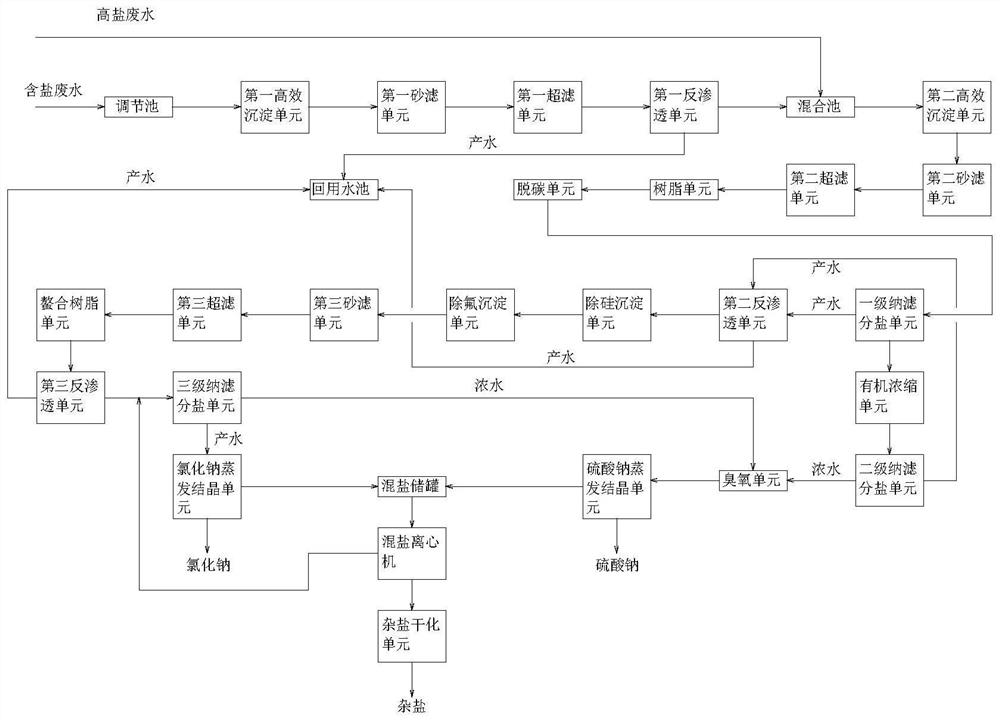

[0041] Embodiment 1: as figure 1 As shown, a coking wastewater advanced treatment system includes a first high-salt wastewater delivery pipe, a first pretreatment system, a second high-salt wastewater delivery pipe, a mixing tank, a second pretreatment system, a three-stage salt separation system and Evaporation and crystallization system; the outlet end of the first high-salt wastewater delivery pipe communicates with the water inlet of the regulating tank of the first pretreatment system; the outlet of the first reverse osmosis unit of the first pretreatment system and the second high-salt wastewater delivery pipe The water outlets of the mixing tank are all connected to the water inlet of the mixing tank; the water outlet of the mixing tank is connected to the water inlet of the second high-efficiency sedimentation unit of the second pretreatment unit; the water outlet of the decarbonization unit of the second pretreatment unit is connected to the third fraction The water i...

Embodiment 2

[0048] Embodiment 2: utilize the method for processing coking waste water of embodiment 1 system, it comprises the following steps:

[0049] (1) Primary pretreatment: TDS 3700mg / L, COD 35mg / L, total hardness 650mg / L, sulfate radical 1000mg / L, chloride ion 1000mg / L, alkalinity 400mg / L, fluoride ion 10mg / L, total silicon The 12mg / L salty wastewater is sent to the first pretreatment system through the first high-salt wastewater delivery pipe, and then passes through the first high-efficiency precipitation unit to remove hard and alkali, and the first sand filter unit and the first ultrafiltration unit to remove SS in the water and colloid, and finally concentrated by the first reverse osmosis unit to obtain concentrated water with a TDS of 16000mg / L. Add sodium hydroxide and sodium carbonate to adjust the pH value of the wastewater in the first high-efficiency precipitation unit to between 11 and 11.5; the total hardness of the effluent from the first high-efficiency precipitatio...

Embodiment 3

[0061] Embodiment 3: utilize the method for processing coking waste water of embodiment 1 system, it comprises the following steps:

[0062] (1) Primary pretreatment: TDS 3000mg / L, COD 30mg / L, total hardness 500mg / L, sulfate radical 500mg / L, chloride ion 500mg / L, alkalinity 350mg / L, fluoride ion 8mg / L, total silicon The 10mg / L salty wastewater is sent to the first pretreatment system through the first high-salt wastewater delivery pipe, and then passes through the first high-efficiency precipitation unit to remove hard and alkali, and the first sand filter unit and the first ultrafiltration unit to remove SS in the water and colloid, and finally concentrated by the first reverse osmosis unit to obtain concentrated water with a TDS of 10,000mg / L, and the produced water is sent to the reuse water tank for reuse, realizing 70% of the water is reused; to the first high-efficiency precipitation unit Add sodium hydroxide and sodium carbonate to adjust the pH value of the wastewater ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com