A method for the integrated removal of nitrate nitrogen in water by ion exchange and denitrification

A technology of ion exchange and nitrate nitrogen, which is applied in the integrated field of nitrate nitrogen removal, can solve the problems of difficult treatment and low nitrate removal rate, and achieve the effects of reduced operating costs, fast and efficient removal, and simple control conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for integrated removal of nitrate nitrogen in water by ion exchange and denitrification, comprising the following steps:

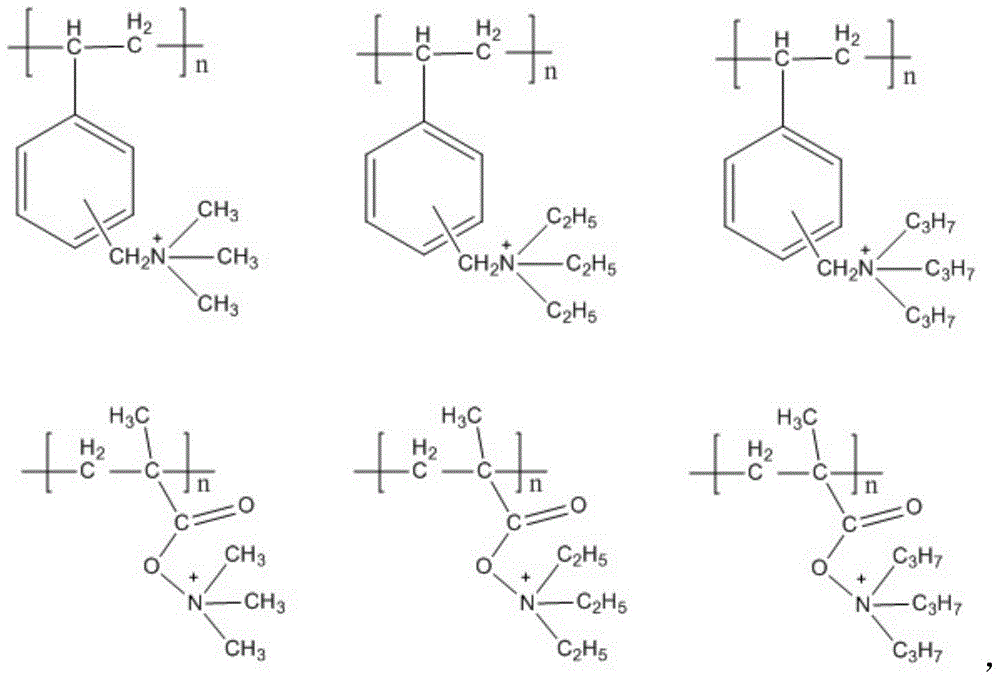

[0043] (1) Pass the waste water containing nitrate nitrogen through the anion exchange resin ( A520E) adsorption tower, the basic structural unit of the anion exchange resin is as follows:

[0044]

[0045] (2) When the concentration of nitrate nitrogen in the effluent of the adsorption tower is 5% of the concentration of nitrate nitrogen in the unadsorbed initial liquid, put the resin of 30% v / v in the adsorption tower into the reactor for regeneration, and add 1 times The resin volume mineral element solution (the mineral element solution is composed of 0.5wt% sodium chloride aqueous solution), the temperature is raised to 33°C at 0.5±0.4°C / min, and the temperature is kept at 33±3°C;

[0046] (3) adding in the system that step (2) obtains is the aerobic sludge of urban sewage treatment plant that is 1:1000 with the mass ratio of mine...

Embodiment 2

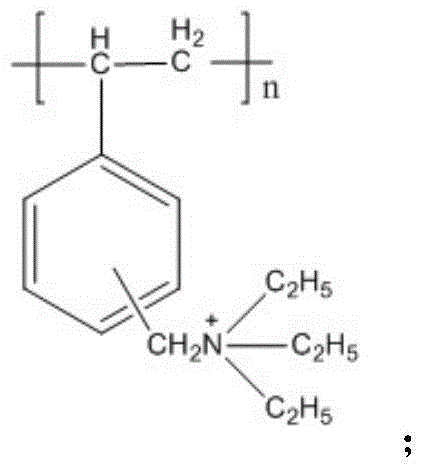

[0054] A method for integrated removal of nitrate nitrogen in water by ion exchange and denitrification, comprising the following steps:

[0055] (1) The waste water containing nitrate nitrogen is passed through an adsorption tower equipped with anion-exchange resin (anion-exchange resin D201 produced in China, Jiangsu Jinkai Resin Chemical Co., Ltd.), and the basic structural unit of this anion-exchange resin is as follows:

[0056]

[0057] (2) When the concentration of nitrate nitrogen in the effluent of the adsorption tower is 10% of the concentration of nitrate nitrogen in the unadsorbed initial liquid, put 50% v / v resin in the adsorption tower into the reaction kettle for regeneration, and add 2 times The resin volume mineral element solution (the mineral element solution is composed of 1wt% potassium chloride aqueous solution), the temperature is raised to 35°C at 1±0.5°C / min, and the temperature is kept at 35±2°C;

[0058] (3) in the system that step (2) obtains, ad...

Embodiment 3

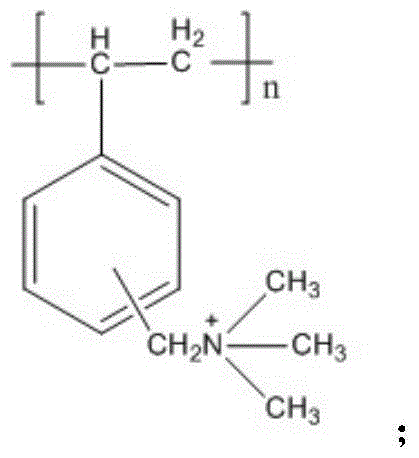

[0066] A method for integrated removal of nitrate nitrogen in water by ion exchange and denitrification, comprising the following steps:

[0067] (1) The waste water containing nitrate nitrogen is passed through an adsorption tower equipped with anion-exchange resin D205 (Jiangsu Jinkai Resin Chemical Co., Ltd.), and the basic structural unit of this anion-exchange resin is as follows:

[0068]

[0069] (2) When the concentration of nitrate nitrogen in the effluent of the adsorption tower is 30% of the concentration of nitrate nitrogen in the unadsorbed initial liquid, the resin of 100% v / v in the adsorption tower is injected into the reactor for regeneration, and 3 times of Mineral element solution of resin volume (mineral element solution is composed of 2.5wt% potassium chloride aqueous solution), the temperature is raised to 35°C at 2±1°C / min, and the temperature is kept at 35°C;

[0070](3) in the system that step (2) obtains, add the biofilm that is loaded on the granu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com