Air separation pre-cooling system

A pre-cooling and air separation technology, applied in refrigeration and liquefaction, liquefaction, solidification, etc., can solve the problems affecting the long-term, safe and stable operation of the air separation unit, the reduction of the working efficiency of the air separation pre-cooling system, and the high temperature of the air at the outlet of the air cooling tower. problems, to achieve the effect of reducing operating costs and maintenance costs, reducing the amount of low-temperature scaling, and reducing the number of shutdowns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the drawings.

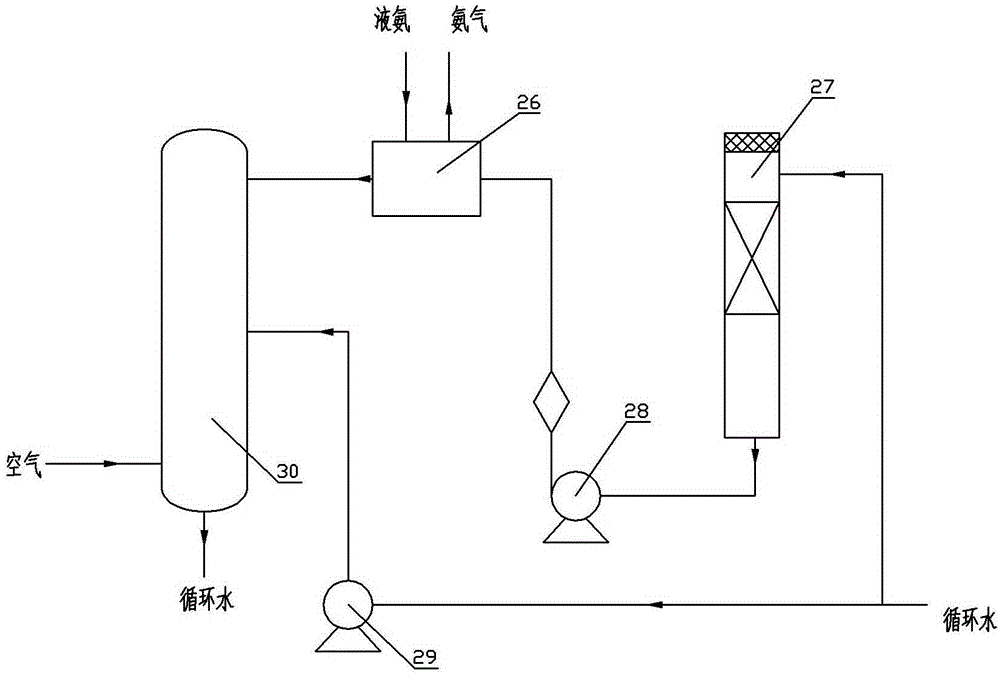

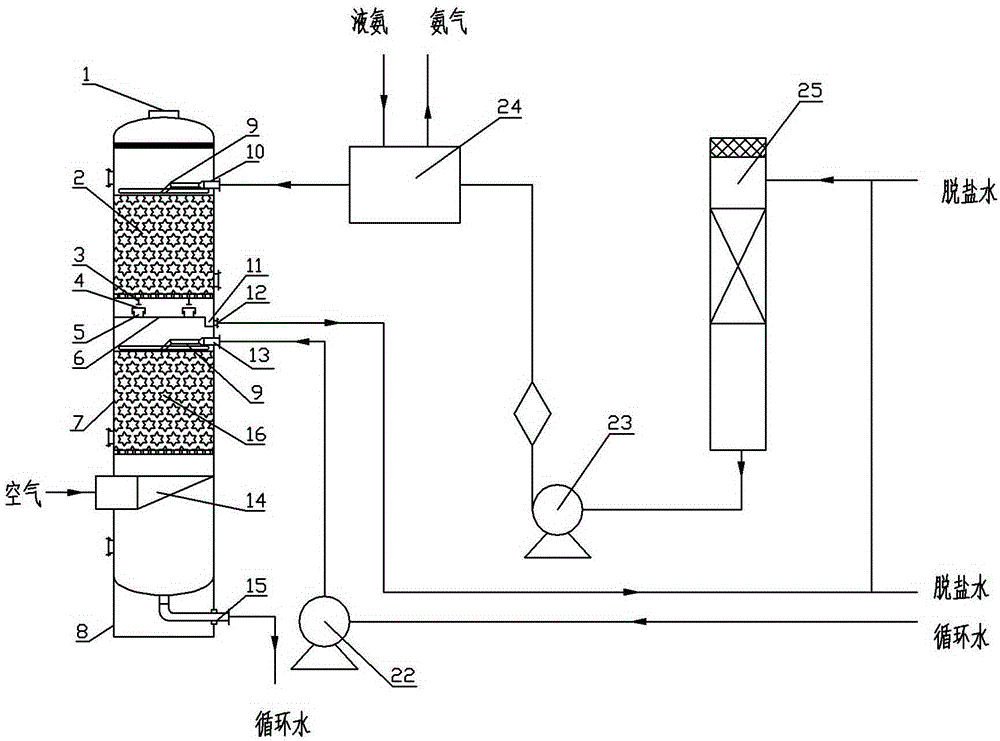

[0022] An air separation pre-cooling system, its structure is as figure 2 As shown, it includes a nitrogen water tower 25, a first pump 23 connected to the bottom of the nitrogen water tower 25, and an ammonia cooler 24 connected to the first pump 23. A double-layer air cooling tower is connected to the ammonia cooler 24.

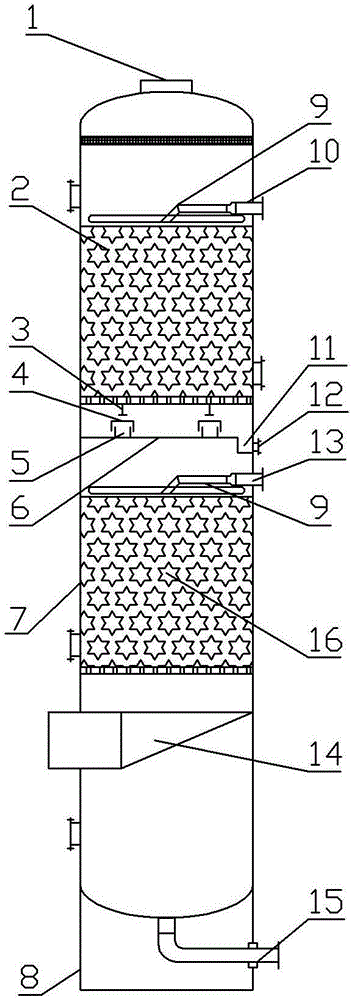

[0023] Such as image 3 As shown, the double-layer air-cooling tower includes a tower body 7, a skirt 8 is provided below the tower body, an air outlet 1 is provided at the top of the tower body 7, an air inlet 14 is provided at the lower part of the tower body 7, and water is provided at the bottom of the tower body 1. At the outlet 15, a partition 6 is arranged in the middle of the tower body 7. The partition 6 divides the space in the tower into an upper cooling tower 2 and a lower pre-cooling tower 16. The partition 6 is provided with an upwardly protruding and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com